1. Purpose

Digital display push-pull gauge is a small, simple, multi-functional and high-precision thrust and pull test instrument, which is widely used in electronic appliances, construction hardware, light industrial textiles, auto parts, lighters and other ignition devices, fire equipment, pen making Push-pull load, insertion force test, destructive test, etc. in lock making, fishing gear, chemical industry, power machinery, scientific research institutions and other industries. The digital display has high resolution, high sampling speed, and easy to use. It is a new generation of high-efficiency and high-precision push-pull force testing instrument.

2. Features

1. High precision and high resolution.

2. Five test modes and three display modes are available (MAX degree improves test efficiency).

3. N (Newton), kg (Kilogram), lb (Pound) three measurement units are available for selection and conversion.

4. Gravity acceleration setting function: The user can input the accurate value of the gravity acceleration of the use place by himself. Make testing and unit conversion more accurate.

5. Peak hold function. Keep the peak display until manually cleared.

6. Automatic peak function, the time can be set freely, from 1 to 9999 seconds.

7. The upper and lower limits can be set for statistical analysis. By setting the upper and lower limits to exceed the limited range, the buzzer can alarm.

8. Data storage function, can store 447 test values.

9. Data output function, the data can be input into the computer through the data line for various analysis. (It can also be applied to multiple instruments to perform various analyses with a computer at the same time.)

10. Green and environmental protection, 10 minutes of no operation automatic shutdown, 10 minutes is the default, you can set the automatic shutdown to the required automatic shutdown time, when the automatic shutdown is set to 0, it will not automatically shut down.

11. High-quality charging power supply. The charging voltage is available from 100V to 240V, which can be adapted to most areas in China and abroad. There are also short-circuit, leakage, and overload protection functions.

12. The unique switch contact on-off force test function makes the switch on-off force test more accurate.

13. 6-bit large screen display.

14. Low battery detection and shutdown. When the battery is low, it will automatically shut down to prevent inaccurate measurement caused by insufficient battery.

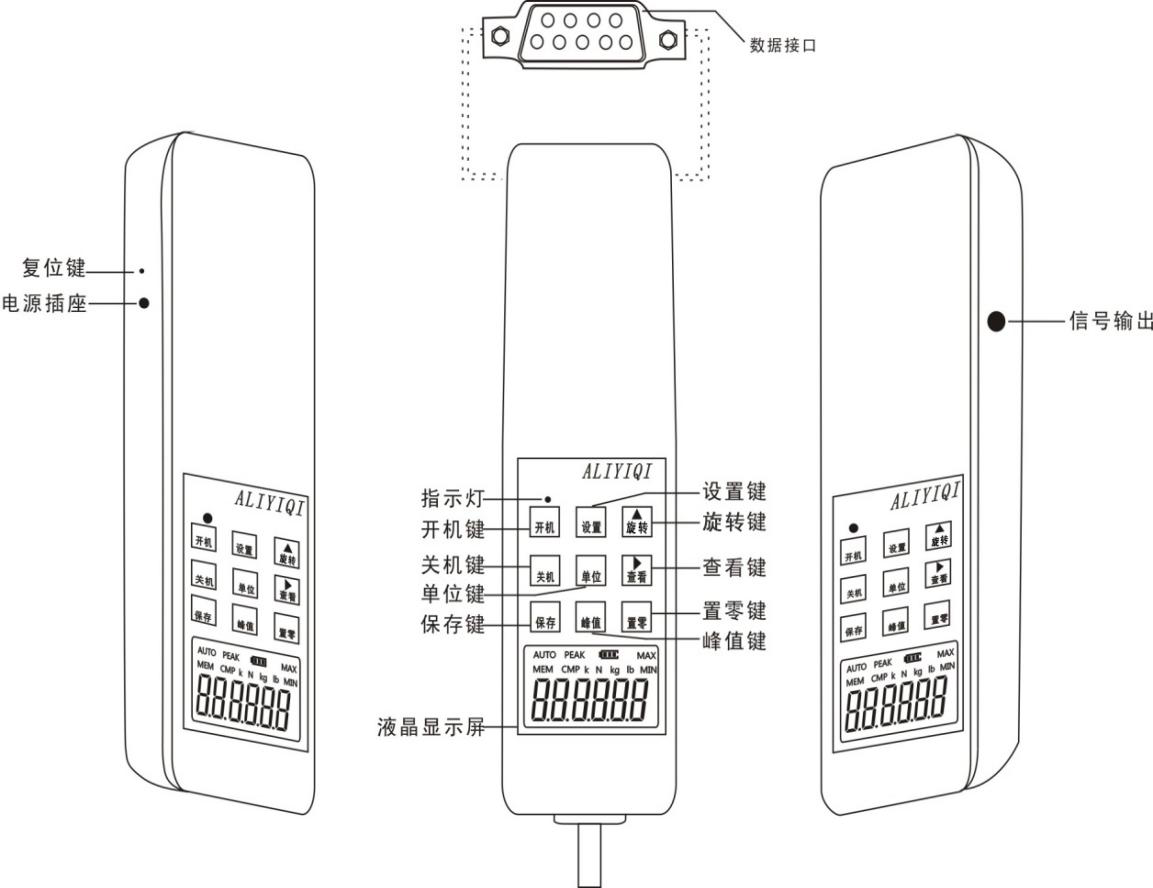

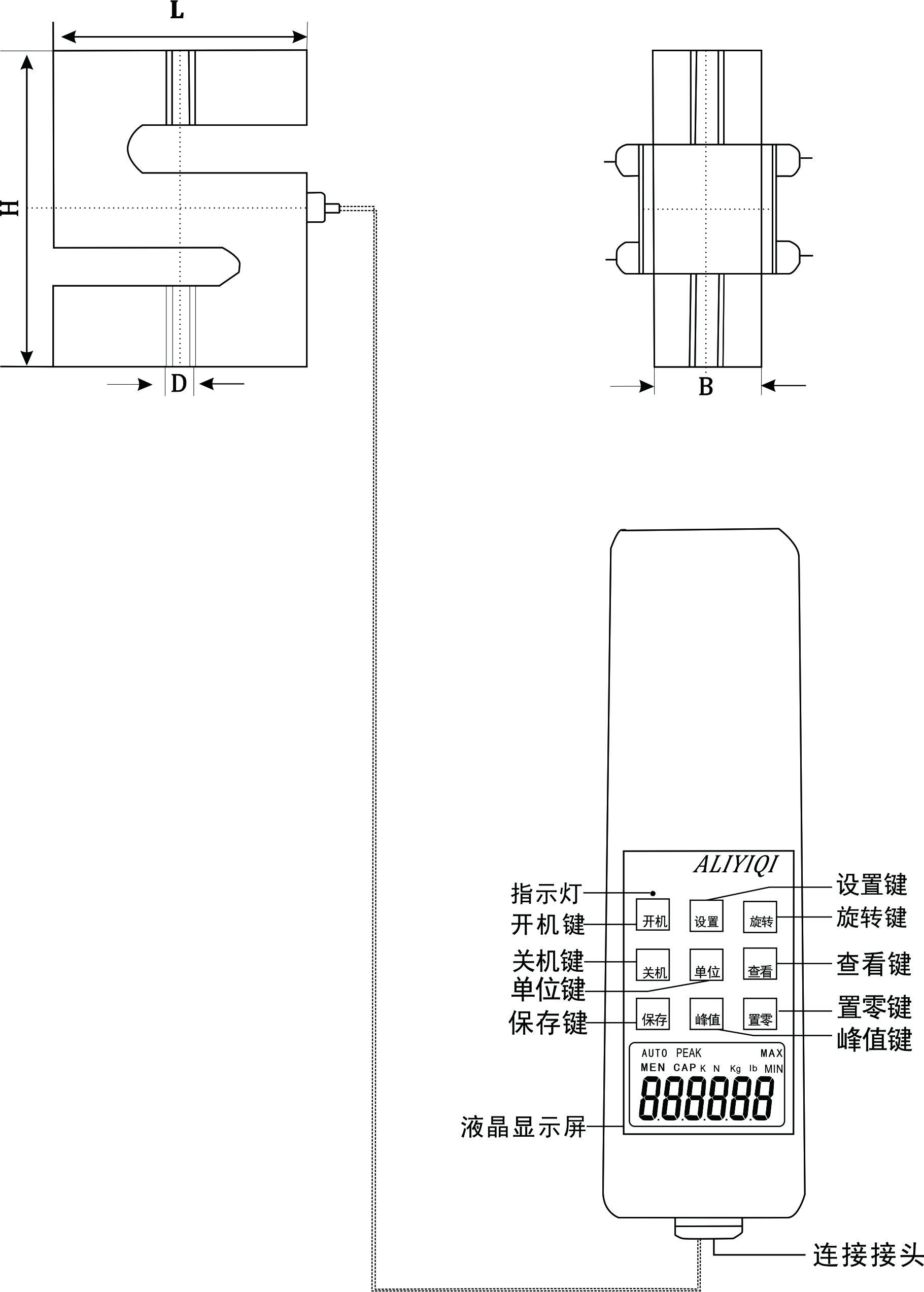

Second, the shape and structure

Built-in sensor

|

Specification range |

Size / mm |

||||

|

Equivalent to |

D |

L |

H |

B |

|

|

50 ~ 500N |

5 ~ 50Kg |

M8 |

51 |

64 |

12.7 |

|

1K ~ 5KN |

100 ~ 500Kg |

M12 |

51 |

76 |

19.1 |

|

10KN |

1t |

M12 |

51 |

76 |

25.4 |

|

20 ~ 50KN |

2 ~ 5t |

M20 |

76 |

108 |

25.4 |

|

100KN |

10t |

M30 |

127 |

178 |

51 |

|

200KN |

20t |

M36 × 3 |

140 |

188 |

60 |

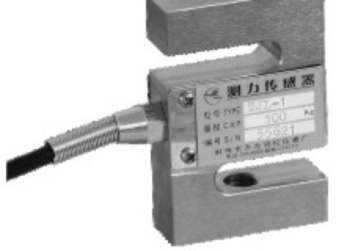

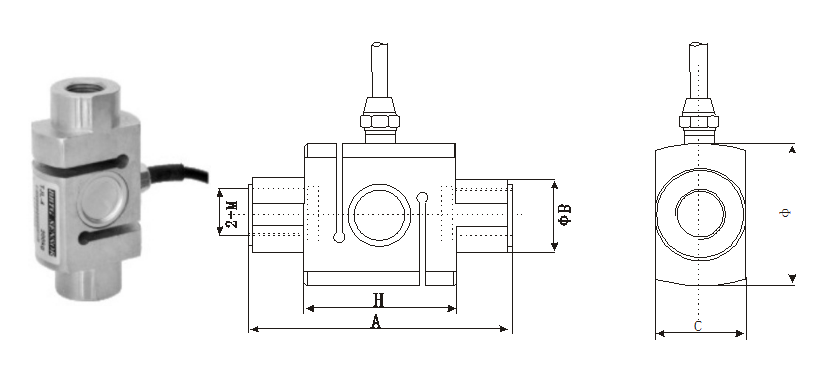

S-type sensor

Sensor external

|

Specification range |

Size / mm |

|||||||

|

Equivalent to |

ΦA |

ΦB |

ΦC |

ΦF |

MD |

H |

E |

|

|

5000N ~ 50KN |

500Kg ~ 5t |

105 |

88.9 |

6.5 |

32 |

M16 × 1.5 |

37 |

34 |

|

100, 200KN |

10 ~ 20t |

125 |

101.6 |

8.5 |

39 |

M32 × 1.5 |

52 |

48 |

|

500KN |

50t |

145 |

116.8 |

10.5 |

50 |

M40 × 1.5 |

58 |

54 |

|

1000KN |

100t |

205 |

162 |

12.5 |

80 |

M60 × 2 |

85 |

78 |

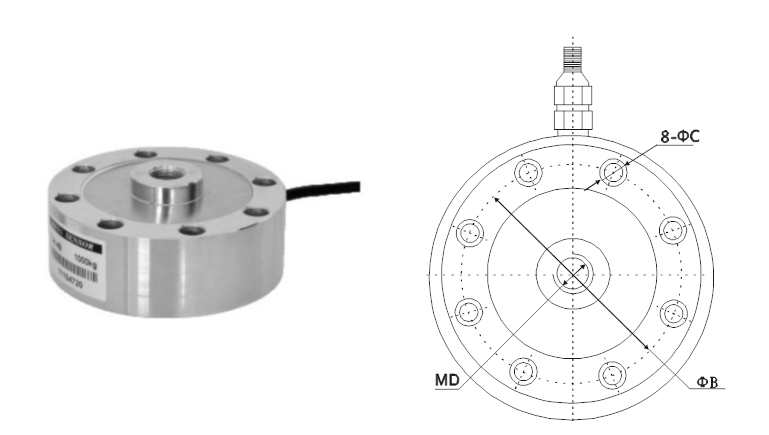

Spoke sensor

|

Specification range |

Size / mm |

||||||

|

Equivalent to |

A |

H |

φB |

φ |

M |

C |

|

|

1000 ~ 5000N |

100 ~ 500Kg |

88 |

58 |

28 |

44 |

16 × 1.5 |

26 |

|

10 ~ 50 |

1 ~ 5t |

120 |

68 |

51 |

63 |

22 |

48 |

|

100 |

10t |

138 |

94 |

60 |

76 |

30 |

56 |

|

200 |

20t |

156 |

108 |

68.5 |

88 |

36 × 3 |

76 |

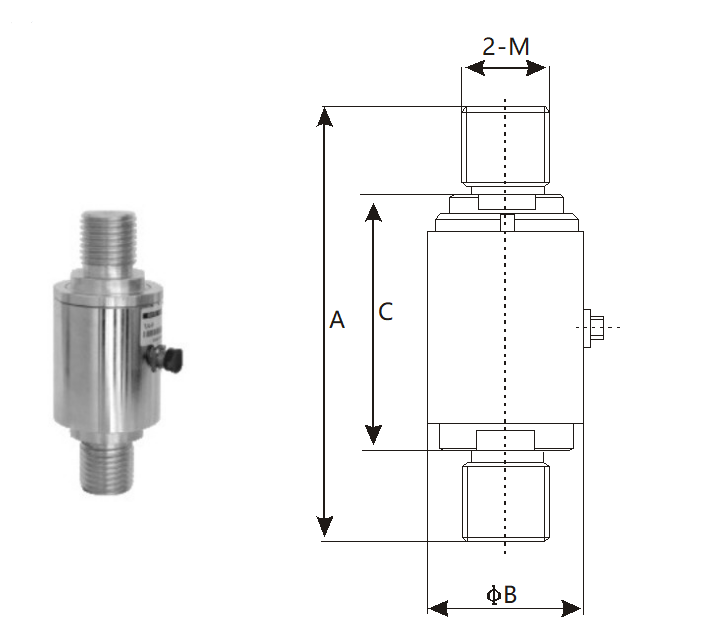

Internal thread cylindrical sensor

|

Specification range |

Size / mm |

||||

|

KN |

Equivalent to t |

A |

ΦB |

C |

M |

|

100 ~ 200 |

10 ~ 20 |

214 |

86 |

124 |

M42 × 4.5 |

|

500 |

50 |

276 |

106 |

156 |

M56 × 5.5 |

|

1000 |

100 |

380 |

142 |

180 |

M90 × 6 |

|

2000 |

200 |

500 |

175 |

220 |

M140 × 10 |

External threaded column sensor

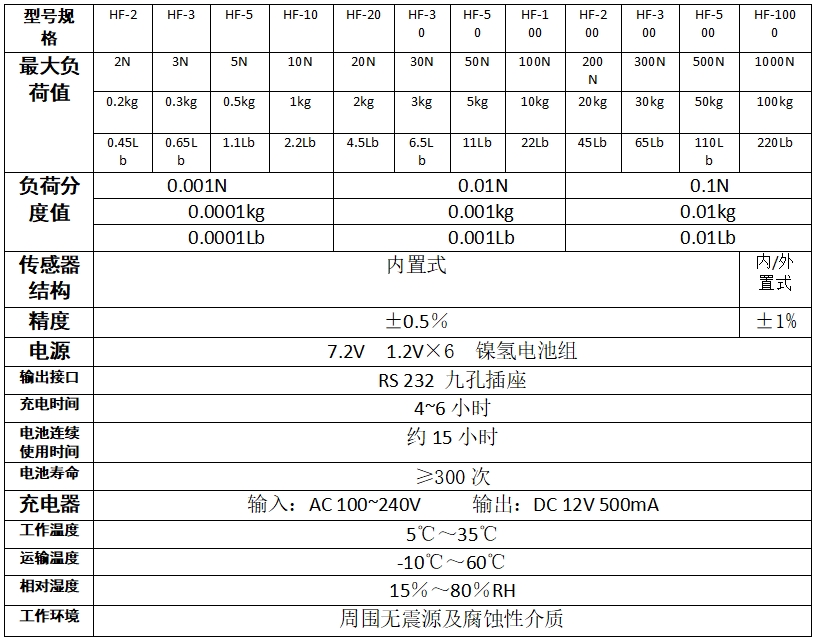

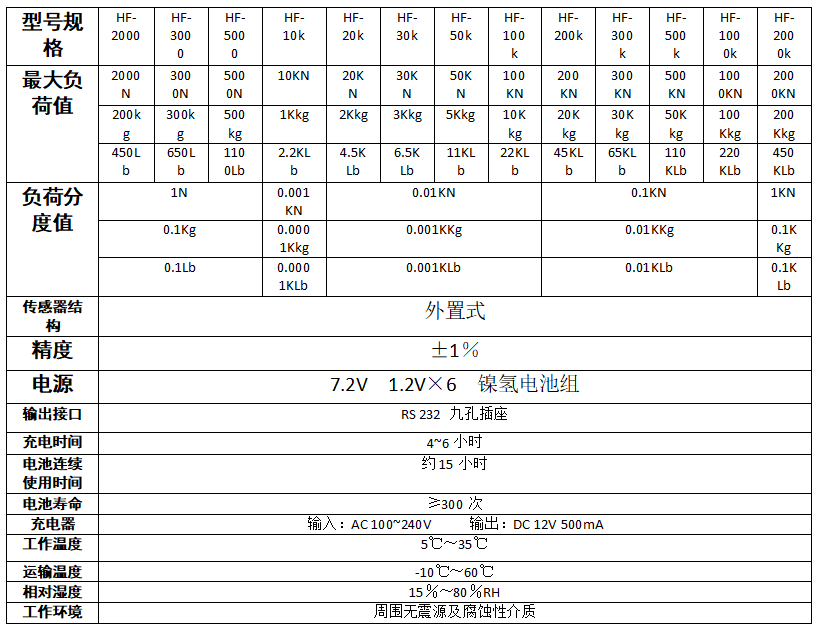

4. Model specifications

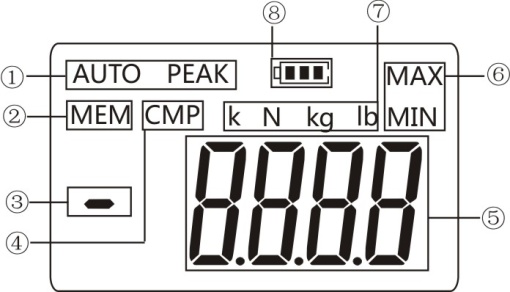

Five, screen display

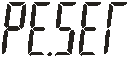

①, three kinds of display: after booting, when there is no character display, it means \"track mode \" (real-time load measurement mode), the value on the screen changes with the change of load; press \"peak \" key here When \"PEAK \" is displayed, it indicates Peak mode (peak hold measurement mode), and the display shows the peak value until it is manually cleared; press \"Peak \" key here, when \"AUTO PEAK \" is displayed, it means \"autopeak \" (Peak hold automatic release measurement mode), automatically save and clear the peak value after displaying the peak value for 10 seconds, the peak time of 10 seconds can be freely set. For details, please refer to the (PE.SET) Explanation}.

(PE.SET) Explanation}.

② With or without data storage display: when there is no \"MEM \" displayed, it means that no data is saved in the instrument; when there is \"MEM \" displayed, it means that there is data saved in the instrument; When you press \"View \" on the measurement interface to view the saved data, \"MEM \" is flashing.

③ Push and pull instructions: In this machine, the thrust (pressure) is displayed as a negative value (\"-\"), and the pulling force is a positive value (\"+ \" is not displayed).

④ Comparison function. When setting the comparison value via STOP (for details, please refer to the (STOP) Machine stop value description), this function is activated. \"CMP \" is displayed. It can be set separately according to need when using.

(STOP) Machine stop value description), this function is activated. \"CMP \" is displayed. It can be set separately according to need when using.

⑤, measurement force value display.

⑥ Display of upper and lower limit values reached: When \"MIN \" is displayed here, it indicates that the measured data reaches and is below the lower limit; when \"MAX \" is displayed here, it indicates that the measured data reaches and The upper limit is exceeded.

⑦, three units display: N (cow), kg (kilogram), lb (pound) three units are displayed separately, converted by pressing the unit key. When HF10K and above specifications, K N (kilo-newton), K Kg (ton), \"K lb (kilo-pound) \" are displayed here.

⑧, power display: when the battery voltage drops below 7.0V, it indicates that the voltage is insufficient and needs to be recharged (it can still be tested during charging). There is a power indicator light above the power button. When the charger is plugged in for charging, the indicator first changes from red to green. This process is repeated twice, indicating that the charging is normal, then the indicator light is red, and the indicator light changes when fully charged Into green. If the instrument is not used for a long time, and the battery power is too low, the indicator light may not light up when the charger is plugged in. After about half an hour, after the battery is woken up, the indicator light will turn red and the charging time will be 4 ~ 6 hours.

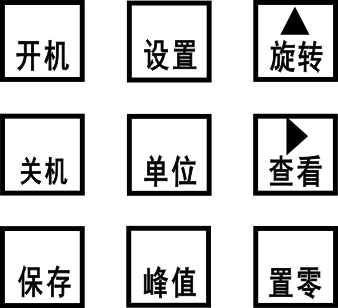

6. Key introduction

1. \"Boot \" key

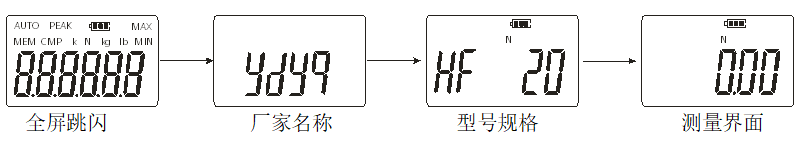

When this button is pressed, the power is turned on and the model number is displayed. After booting, before you press \"Clear \" to clear, the zero drift value of the analog signal may be displayed on the screen, just press \"Clear \" to clear.

2. \"Shutdown \" key

In the power-on state, when you press this button, the power is turned off, but the stored data will not disappear. When the power is turned on (that is, when the model is displayed and the measurement interface 0.00 is not displayed), pressing the shutdown key at this time is unresponsive.

3. \"Save \" key

In the peak measurement interface state, press this key to save the test data displayed on the screen; in the function setting interface state, press this key to save the set parameters. When the test data is stored in the machine, \"MEM \" is displayed. This machine can store 447 data.

4. \"Settings \" key

For detailed settings, please refer to the description of various setting methods in \"Function Introduction \".

5. \"Unit \" key

Press this key to switch between measurement units, and three units of N (Newton), kg (Kilogram), and lb (Pound) can be displayed cyclically. In the test data display state, the unit conversion of the same value can also be completed. In the specifications above HF10K, it is composed of the letters \"K \" \"KN (kilo-newton) \", \"Kkg (ton) \", \"Klb (kilo-pound) \".

6. \"Peak \" key

Each time you press this key, there will be a switch between \"PEAK \" display, \"AUTO PEAK \" display or \"PEAK \" disappearing-that is, peak hold, peak hold automatic release, and real-time load value switching.

7. \"Rotate \" key

This key is only valid in the test interface. When you press this key, the measured value displayed on the screen will rotate 180 degrees.

8. \"View \" key

When you press this key, the stored test data will be recalled and displayed on the screen. At this time, the word\"\" MEM \"flashes-the number of saves is displayed first, and the saved data is automatically displayed after 2 seconds. Press \"Zero \" to return to the measurement interface.

9. \"Zero \" key

When this key is pressed, the test value on the screen will be reset to zero. Note: When the instrument is cleared, the instrument can only be cleared in the real-time measurement mode under peak and automatic peak.

※ Choose a lighter fixture or remove the added load and clear it again.

※ In the \"View \" interface, press and hold this button for 4 seconds, all the stored test data can be cleared (may not be cleared in some states, then restart the machine after shutdown and then execute this function to clear all saved data) .

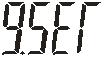

Seven, boot display

Eight, function introduction

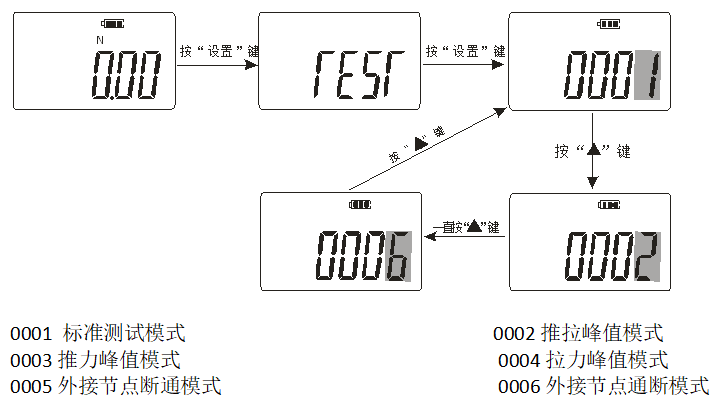

1. Setting function

a. Mode switching: After the boot is complete, press \"Settings \" key, \"TEST \" appears, press \"Settings\" key again, 0001 mode appears, use \"Keys can choose different modes. As shown in the figure below:

\"Keys can choose different modes. As shown in the figure below:

0001 Standard test mode (factory default mode): In this mode, three states can be set, namely real-time load state, peak hold state and automatic peak state. When there is no \"PEAK \" on the display, it is the real-time value state of the load, and the test value changes with the change of the load; press \"Peak \" key, when the word \"PEAK \" is displayed, it is the peak hold state The displayed test value is the MAX value of the test (regardless of tension and pressure), which needs to be cleared manually; press \"Peak \" key again, \"AUTO PEAK \" display, it is the automatic peak state, the displayed test The value is the MAX value in the test (regardless of tension and pressure), and it will automatically disappear after returning to zero for 2 seconds, and the next test can be performed.

0002 Push-pull peak mode: the function of simultaneously grasping the MAX load value in both directions of pressure and tension. When testing the connector, grasp the function of the MAX load on both the positive and negative sides of the insertion force and the extraction force.

0003 Peak thrust mode-only the MAX load function of insertion pressure is grabbed during the plug-in test

0004 Tension peak mode-when plugging and unplugging, only the function of MAX load that pulls out the tension is captured.

0005 0006 Switch contact on-off force test mode-accurately measure the load value at the moment of contact on and off action.

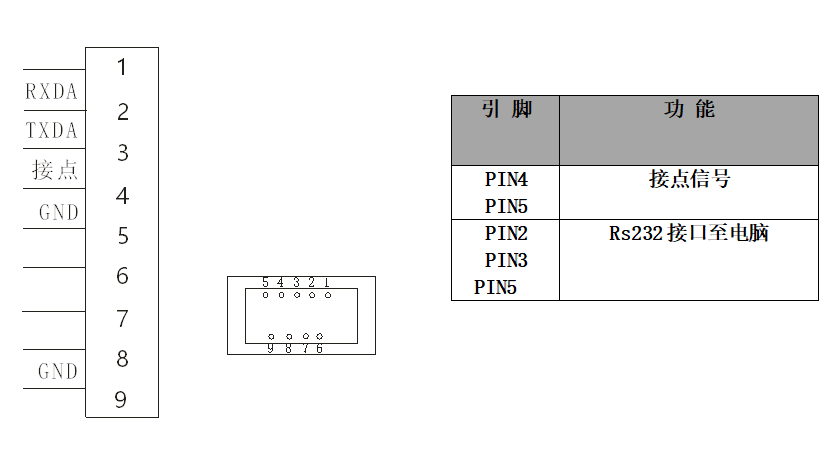

0005 The maximum force value of the external node from the moment of disconnection to the moment of connection. Connect the two tested contacts to pins 4 and 5 of the data interface, press \"Peak \" to select the peak mode, and apply pressure to the switch through the push-pull force gauge until the switch is turned on. The measured force value at this time is the force value required to turn on the switch.

0006 The MAX value of the external node from on to off. Connect the two tested contacts to pins 4 and 5 of the data interface (using the data plug in the accessory), press the\"\" peak\"key, select the peak mode, and apply pressure to the switch through the push-pull force gauge until When the switch is open, the measured force value at this time is the force value required to open the switch.

b. Various setting items

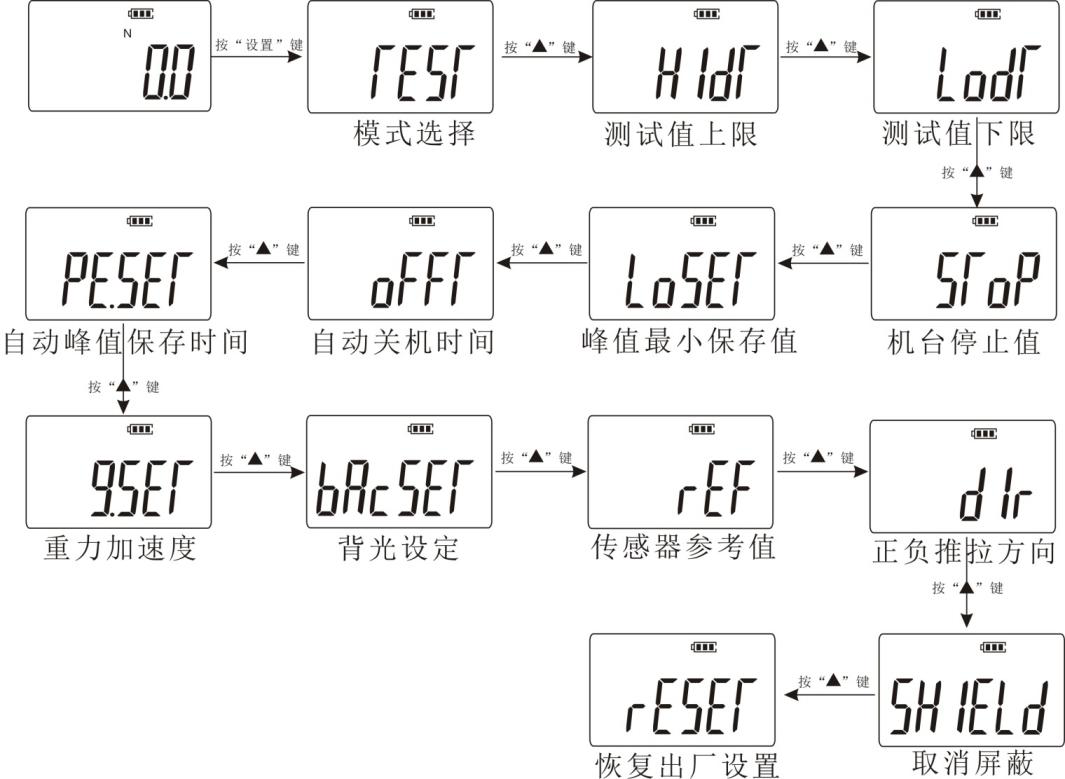

Press \"Settings \" key in the boot state, the display is \"TEST \", then press \" \"Key, you can view the setting options. \" HIDT \", \" LODT \", \" STOP \", \" LOSET \", \" OFFT \", \" PE.SET \", \"GSET \", \"BACSET \", \"RESET \". As shown below:

\"Key, you can view the setting options. \" HIDT \", \" LODT \", \" STOP \", \" LOSET \", \" OFFT \", \" PE.SET \", \"GSET \", \"BACSET \", \"RESET \". As shown below:

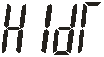

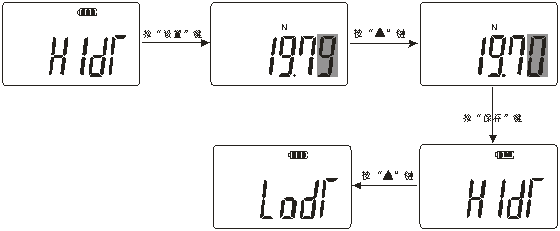

(HIDT) Test value upper limit setting: Set the test value upper limit, the upper limit default state is 99% of full scale. Above the upper limit is out of range, \"MAX \" is displayed. If you want to reset the upper limit, use \"

(HIDT) Test value upper limit setting: Set the test value upper limit, the upper limit default state is 99% of full scale. Above the upper limit is out of range, \"MAX \" is displayed. If you want to reset the upper limit, use \" \"Key and \"

\"Key and \" \"Key setting. \" Save \"and return to the setting item interface. As shown below:

\"Key setting. \" Save \"and return to the setting item interface. As shown below:

(LODT) Test value lower limit setting: Set the test value lower limit, the default value is 0 by default. Below the lower limit is out of range, \"MIN \" is displayed. If you want to reset the lower limit, it is similar to the previous operation, use \"

(LODT) Test value lower limit setting: Set the test value lower limit, the default value is 0 by default. Below the lower limit is out of range, \"MIN \" is displayed. If you want to reset the lower limit, it is similar to the previous operation, use \" \"Key and \"

\"Key and \" \"Key setting. \" Save \"and return to the setting item interface.

\"Key setting. \" Save \"and return to the setting item interface.

(STOP) The machine stop value setting, the default state is 99% of full scale. This product is used in combination with our own motor table. When the test value exceeds the set machine stop value, the instrument outputs a 5V signal and the machine receives the signal.

(STOP) The machine stop value setting, the default state is 99% of full scale. This product is used in combination with our own motor table. When the test value exceeds the set machine stop value, the instrument outputs a 5V signal and the machine receives the signal.

Operation method of this function:

a. Set the machine stop value for this instrument first: Setting method: Turn on, when the measurement interface is displayed, press \"Settings\" to enter the machine stop value setting (display After (STOP), set its value to the preset value.

After (STOP), set its value to the preset value.

b. There is a signal output jack on the right side of this instrument (see \"Outline Structure Diagram \" above). Insert one end of the signal output line into this jack (socket) and the other end into the electric test bench produced by our company The jack (socket) marked as signal input on the top (this signal output line is the standard accessory of the electric test bench).

c. Starting the electric test bench produced by our company can realize the function that the motor stops automatically when the test force exceeds the stop value of the machine.

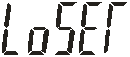

(LOSET) Minimum saved value of peak value:MIN peak save value. In peak mode, when the current value is less than this value, the peak value will not be saved.

(LOSET) Minimum saved value of peak value:MIN peak save value. In peak mode, when the current value is less than this value, the peak value will not be saved.

(OFFT) Automatic shutdown time setting: under this setting item, use \"

(OFFT) Automatic shutdown time setting: under this setting item, use \" \"Key selection, you can set 10 minutes to 90 minutes to automatically shut down, you can also set \" 00 \"does not automatically shut down. If you do not choose to shut down automatically, press \" Save \"after selection to complete the setting. That is Return to the option interface. The default setting of the instrument is 10 minutes.

\"Key selection, you can set 10 minutes to 90 minutes to automatically shut down, you can also set \" 00 \"does not automatically shut down. If you do not choose to shut down automatically, press \" Save \"after selection to complete the setting. That is Return to the option interface. The default setting of the instrument is 10 minutes.

(PE.SET) Automatic peak save time: automatic peak save time, the unit is second, the default value is 10, the setting cannot set this value to 0.

(PE.SET) Automatic peak save time: automatic peak save time, the unit is second, the default value is 10, the setting cannot set this value to 0.

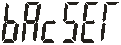

(BACSET) Backlight function setting: under this setting item, use \"

(BACSET) Backlight function setting: under this setting item, use \" \"Key selection, if selected \"

\"Key selection, if selected \" (YES) \"means turn on the backlight function, choose \"

(YES) \"means turn on the backlight function, choose \" (NO) \"means to turn off the backlight, press \" Save \"to save and return to the setting item interface after selection.

(NO) \"means to turn off the backlight, press \" Save \"to save and return to the setting item interface after selection.

(REF) Sensor reference value: manufacturer reference value, users do not need to pay attention.

(REF) Sensor reference value: manufacturer reference value, users do not need to pay attention.

(DIr) Positive and negative push-pull direction: used to switch the positive and negative direction of the push-pull force gauge.

(DIr) Positive and negative push-pull direction: used to switch the positive and negative direction of the push-pull force gauge.

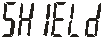

(SHIELD) Cancel the mask: Cancel the mask to display data below 1% of full scale. Press \"YES \" to not cancel, press \"NO \" to cancel.

(SHIELD) Cancel the mask: Cancel the mask to display data below 1% of full scale. Press \"YES \" to not cancel, press \"NO \" to cancel.

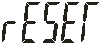

(RESET) Factory reset function:Under this setting item, press \"Settings \" to restore the factory settings, and the machine will shut down. If you use the machine to restart the machine.

(RESET) Factory reset function:Under this setting item, press \"Settings \" to restore the factory settings, and the machine will shut down. If you use the machine to restart the machine.

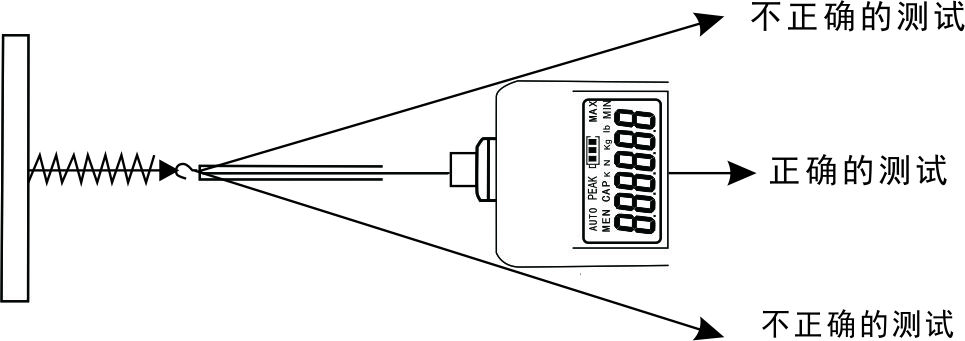

Nine, test

Press \"Power On \" key to turn on the power, and use the factory default settings as needed to directly test or press the Set key to select the test mode and test.

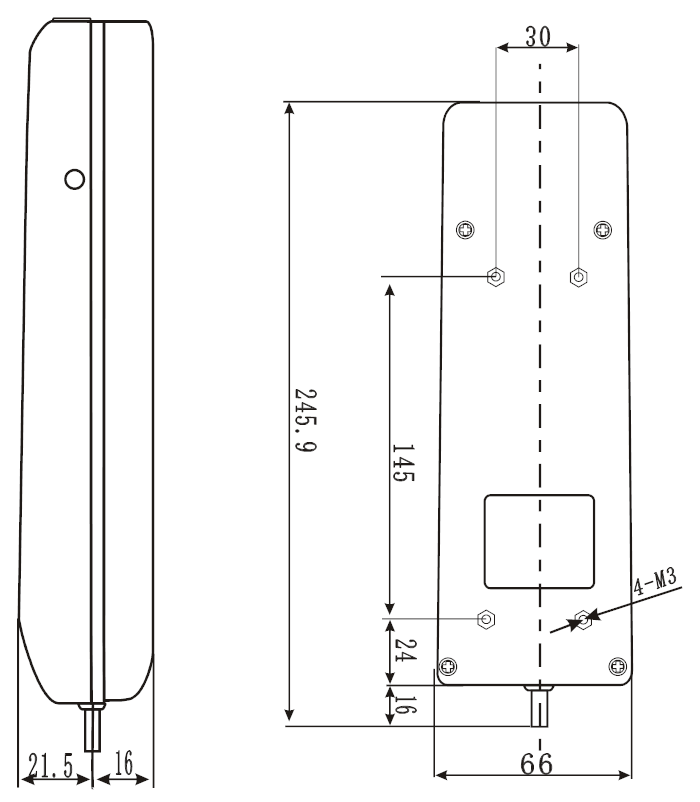

1. Select the appropriate test joint fixture to be installed on the push-pull force gauge (for self-made fixtures, please refer to the relevant data in \"Outline and Installation Dimensions \".

2. Please hold the push-pull force gauge firmly or install the push-pull force gauge on a suitable test machine for testing. During the test, please make the tested force and the push-pull rod of the push-pull force gauge in line to measure the accurate load .

3. After the test is completed, unload the load, turn off the power, remove the fixture, and clean the objects back into the tool box for the next use.

10. Introduction to storing data and connecting to a computer

1. Store data

Press \"Save \" to save the data. The saved value is the value displayed on the current screen. \"MEM \" will appear on the display. The stored data can also be saved after shutdown. When you use the\"\" View\"\" key to view the saved data, \"MEM \" flashes, the number of saves appears first, and the saved value automatically appears after 2 seconds. Press \"Clear \" key to exit save and enter test directly. Data can also be input into a computer for analysis and processing. This machine can store 447 data. When there are more than 447 data, the subsequent data will not be saved.

2. Data clearing

When viewing the interface, press the\"zero\" key for more than four seconds, all the saved data will be cleared, and the word\"MEM\" will disappear.

3. Introduction to connecting to a computer

a. Use the\"Data Export Program\" in the CD-ROM to export the data saved in the instrument to the computer. View, print, test times, average value, MAX value, MIN value and judge whether the test result meets the set requirements. (For details, please refer to the description in\"Data Export Program\")

b. Use the\"Synchronization Test\" in the CD to realize the curve of force value and time. (For details, please refer to the description in\"Synchronization Test\")

4. If connecting with PLC, modbus protocol needs to be customized.

11. Safety Precautions

1. Matters needing attention:

a. If you purchase this instrument, you need to charge it for 4 ~ 6 hours before it can be used normally.

b. To purchase this instrument, you must use the RS232 computer cable included in the company's distribution accessories.

c. If the operation is wrong, it may damage the instrument or cause serious accidents. This manual points out important matters for preventing accidents and how to use the instrument. Please read this manual carefully before use, and keep it properly after reading to prepare for reading here.

d. If you are testing the impact load, please select the model whose MAX load is twice the impact load to be tested.

2. Warning matters:

a. During destructive testing, protective masks and gloves should be worn to prevent the splashed material from hurting the human body during the testing process.

b. Do not use damaged or severely bent fixtures. For self-made fixtures, please refer to the relevant parameters in this manual (the company also provides various fixtures, customers can choose according to need; purchase separately).

C. Do not use the instrument beyond the MAX range. Otherwise, the sensor may be damaged or even an accident may occur.

d. When the test value exceeds 100% of full scale, the buzzer will continue to sound. In this case, please quickly release the added load or reduce the load. When the test value exceeds 120% of full scale, the instrument may be damaged.

3. Solve the crash status: When the instrument crashes unexpectedly, use a small round rod with a hard object to press the\"Reset\" button on the left side of the instrument to quickly reset and shut down.

4. Safety matters:

a. Please use the matching charger to charge, otherwise it will cause circuit failure and even fire.

b. Do not use a power supply other than the rated voltage of the charger, otherwise it may cause electric shock or fire.

c. Do not pull out or insert the power supply with wet hands, otherwise it may cause electric shock.

d. Do not pull the power cord of the charger to pull out the plug, so as to avoid the electric cord being broken and being subjected to electric shock.

e. Please clean the machine with a soft cloth. Immerse the cloth in water soaked with detergent and wring it out to remove dust and dirt. Note: Do not use volatile chemicals to clean the machine (such as volatile agent, thinner, alcohol, etc.).

f. Do not operate the machine in the following environment

①Humid environment

②Dusty environment

③ Where oil or chemicals are used

④ Places with earthquake sources around

g. Please use and store within the specified temperature and humidity range, otherwise it may cause malfunction of the instrument.

h. Do not dismantle, repair or modify the machine by yourself, these actions may cause the instrument to malfunction.

i. Other matters that need to be paid attention to in safety production.

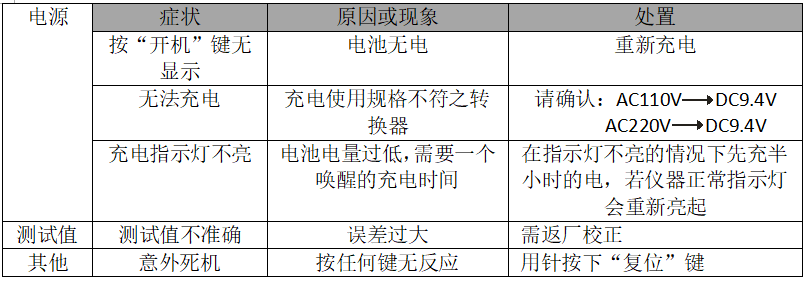

J, HF series push-pull force meter confirmation items before repair

12. Data interface (9PIN)

Thirteen, outline and installation dimensions

14. List of random attachments

|

|

charger |

Compression fixture |

Stretching fixture |

Extension rod |

Mounting screws |

Instructions |

Inspection certificate |

Certificate of conformity |

|

HF-2 |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-3 |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-5 |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-10 |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-20 |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-30 |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-50 |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-100 |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-200 |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-300 |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-500 |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-1000 (built-in) |

1 |

4 |

1 |

1 |

4 |

1 |

1 |

1 |

|

HF-1000 (external) |

1 |

3 |

2 |

- |

4 |

1 |

1 |

1 |

|

HF-2000 |

1 |

3 |

2 |

- |

4 |

1 |

1 |

1 |

|

HF-3000 |

1 |

3 |

2 |

- |

4 |

1 |

1 |

1 |

|

HF-5000 |

1 |

3 |

2 |

- |

4 |

1 |

1 |

1 |

|

HF-10K |

1 |

3 |

2 |

- |

4 |

1 |

1 |

1 |

|

HF-20K |

1 |

3 |

2 |

- |

4 |

1 |

1 |

1 |

|

HF-30K |

1 |

3 |

2 |

- |

4 |

1 |

1 |

1 |

|

HF-50K |

1 |

3 |

2 |

- |

4 |

1 |

1 |

1 |

|

HF-100K |

1 |

3 |

2 |

- |

4 |

1 |

1 |

1 |

|

HF-200K |

1 |

3 |

2 |

- |

4 |

1 |

1 |

1 |

|

HF-300K |

1 |

- |

- |

- |

4 |

1 |

1 |

1 |

|

HF-500K |

1 |

- |

- |

- |

4 |

1 |

1 |

1 |

|

HF-1000K |

1 |

- |

- |

- |

4 |

1 |

1 |

1 |

|

HF-2000K |

1 |

- |

- |

- |

4 |

1 |

1 |

1 |

(G.SET)

(G.SET)