SF simple push-pull force gauge

user's Guide

1. Purpose

SF series digital display push-pull force meter is a new generation of digital display push-pull force meter developed by our company. The volume is 1/2 of the original, which is convenient for users to carry around. It is an easy-to-operate thrust and pull test instrument. It is widely used in the push-pull load test, insertion force test and destruction test of various products. It can be combined with various machines and fixtures to form small-scale experimental machines for different purposes.

2. Features

1. Digital display, easy to read and high precision.

2. Light weight and small size, easy to carry.

3. Unit display: N, Kg and Lb switch between each other.

4. The battery has short-circuit, leakage, and overload protection. The battery has a low battery reminder. It is powered by a 3.7V lithium battery and will automatically shut down after 10 minutes of no operation.

5. There are two measurement modes: real-time, peak free switch.

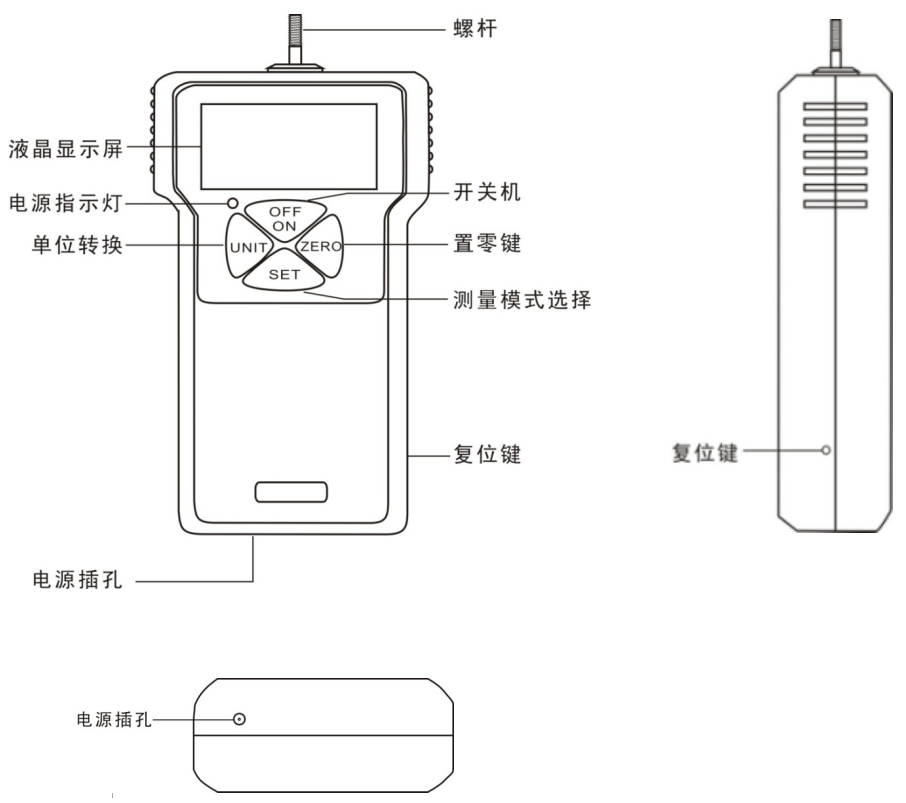

3. Shape and structure

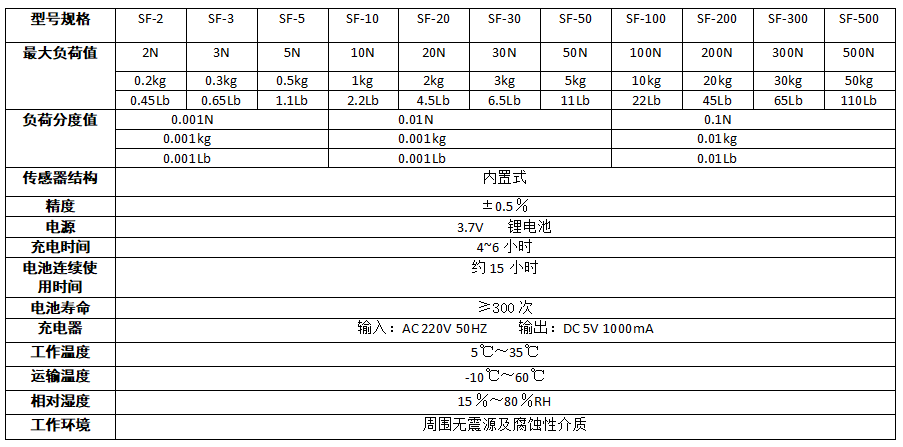

4. Specifications

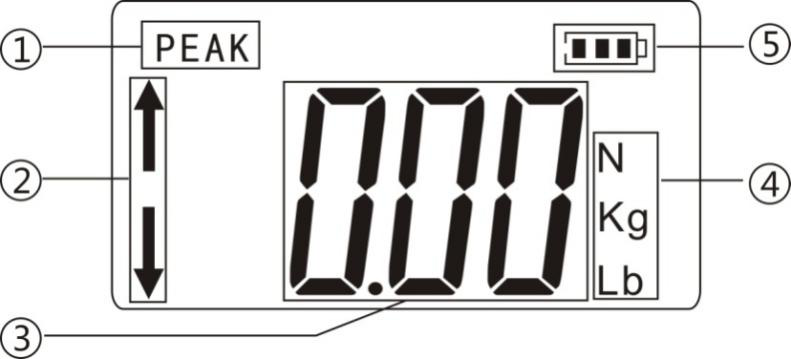

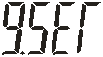

Five, screen display

① Peak mode: After power on, enter the measurement interface, press \"SET \" key, you can enter \"peak mode \", record the maximum force value measured in a period of time.

② Push-pull force means: the push-pull force meter does not move, the upper arrow shows the pulling force, and the lower arrow shows the pushing force.

③, the measured force value display.

④, three units display: N (cow), kg (kg), lb (pound) three units are displayed separately, press \"UNIT \" key to convert.

⑤, power display.

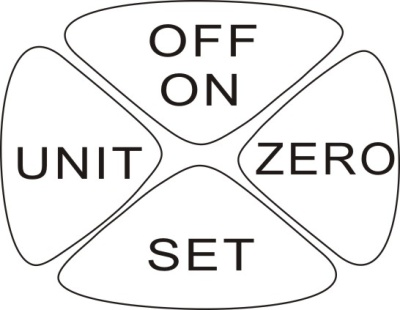

6. Key introduction

OFF / ON (\"Power On / Off \" key): When this key is pressed, the power is turned on and the measurement interface appears. When shutting down, press this key again to shut down.

ZERO (\"Zero \" key): When you press this key, the test value on the screen will be reset to zero.

SET (\"mode switch \" key): When this key is pressed, the peak measurement mode is entered. Press \"SET \" to enter the setting item interface.

UNIT (\"unit switch \" key): When this key is pressed, three different units can be switched.

Seven, boot display

Eight, function introduction

a. Setting items:

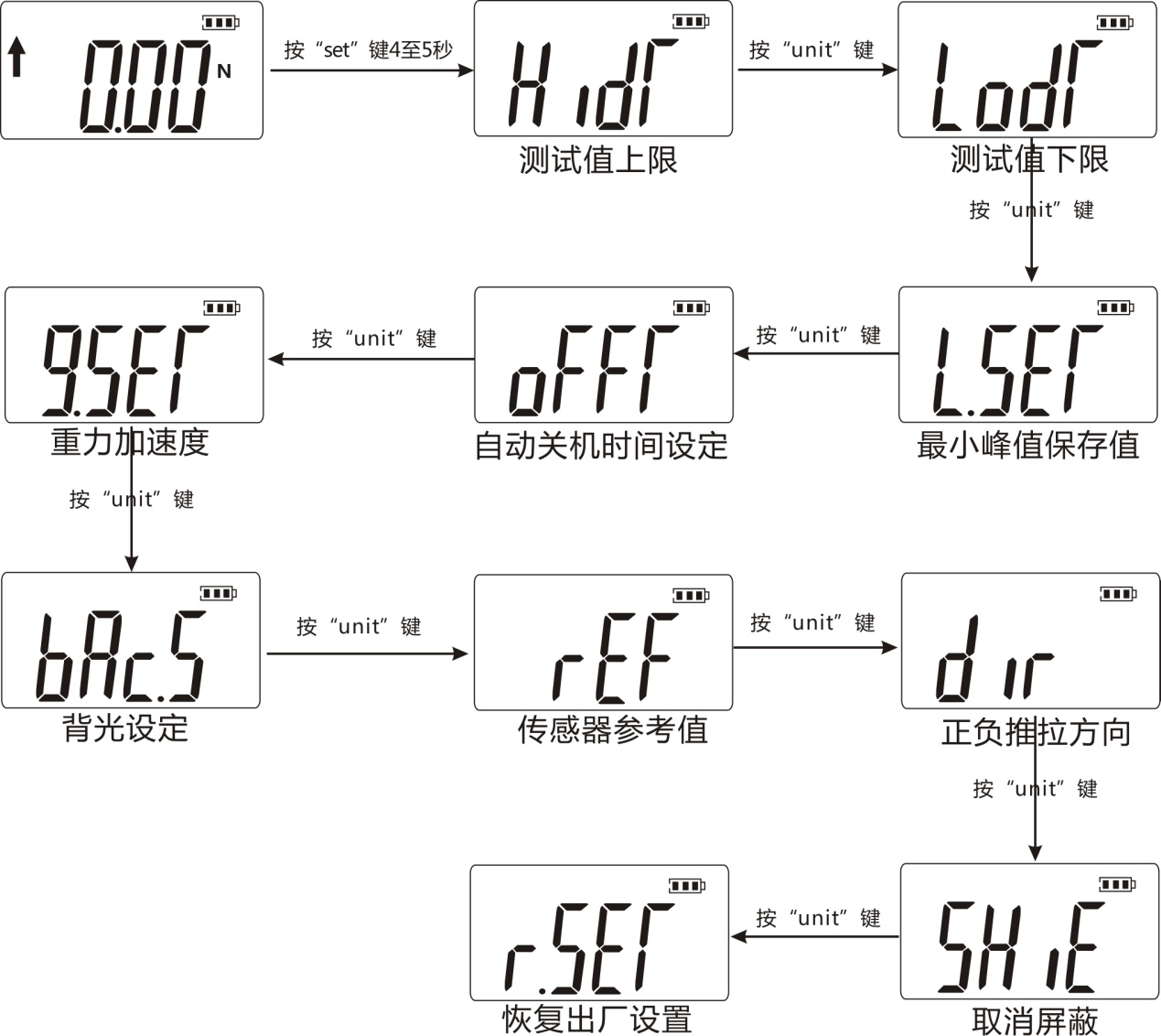

After booting, press \"SET \" key for 4 to 5 seconds, and then release, then enter the setting interface, display \"HIDT \", then press \"UNIT \" continuously, other setting items will appear in sequence: \"LODT \", \" L.SET \", \" OFFT \", \" G.SET \", \" BAC.S \", \" R.SET \", as shown below:

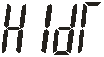

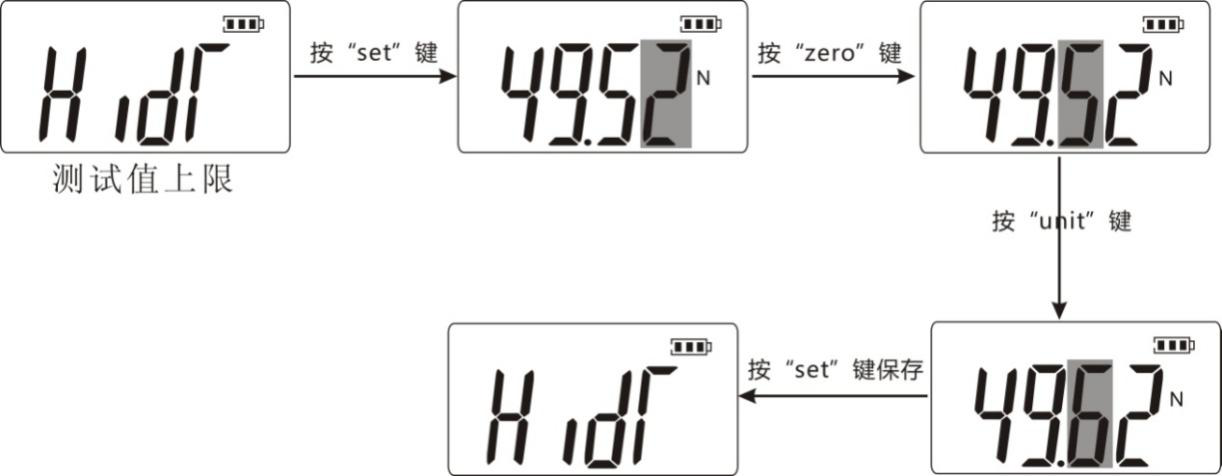

(HIDT) Test value upper limit setting: Set the test value upper limit, the upper limit default state is 99% of full scale. Above the upper limit is out of range, the instrument will beep. If you want to reset the upper limit value, you can use the\"UNIT\" key and\"ZERO\" key to set. Press \"SET \" to save and automatically return to the setting item interface. As shown below:

(HIDT) Test value upper limit setting: Set the test value upper limit, the upper limit default state is 99% of full scale. Above the upper limit is out of range, the instrument will beep. If you want to reset the upper limit value, you can use the\"UNIT\" key and\"ZERO\" key to set. Press \"SET \" to save and automatically return to the setting item interface. As shown below:

(LODT) Test value lower limit setting: Set the test value lower limit, the default value is 0 by default. Below the lower limit is out of range, and the instrument will beep. If you want to reset the lower limit value, it is similar to the previous operation, use \"UNIT \" and \"ZERO \" to set. Press \"SET \" to save and automatically return to the setting item interface.

(LODT) Test value lower limit setting: Set the test value lower limit, the default value is 0 by default. Below the lower limit is out of range, and the instrument will beep. If you want to reset the lower limit value, it is similar to the previous operation, use \"UNIT \" and \"ZERO \" to set. Press \"SET \" to save and automatically return to the setting item interface.

(L.SET)Peak minimum saved value:The minimum peak saved value. In peak mode, when the current value is less than this value, the peak value will not be saved.

(L.SET)Peak minimum saved value:The minimum peak saved value. In peak mode, when the current value is less than this value, the peak value will not be saved.

(OFFT) Automatic shutdown time setting: under this setting item, use\"UNIT\"Key and \"ZERO\"Key setting,Can be set1Minutes to9999Automatic shutdown in minutes, can also be set \"00\"No automatic shutdown. If not, please press \"SET\"Key to complete the setting. Return to the option interface. The default setting of the instrument is10minute.

(OFFT) Automatic shutdown time setting: under this setting item, use\"UNIT\"Key and \"ZERO\"Key setting,Can be set1Minutes to9999Automatic shutdown in minutes, can also be set \"00\"No automatic shutdown. If not, please press \"SET\"Key to complete the setting. Return to the option interface. The default setting of the instrument is10minute.

(G.SET) Gravity acceleration setting: The user can set the gravity acceleration value according to the location of the region, the default value is9.800。

(G.SET) Gravity acceleration setting: The user can set the gravity acceleration value according to the location of the region, the default value is9.800。

(bAC.S)Backlight function setting: Under this setting item, use\"UNIT\"Key selection, if selected \"

(bAC.S)Backlight function setting: Under this setting item, use\"UNIT\"Key selection, if selected \" (YES)\"Indicates to turn on the backlight function, select \"

(YES)\"Indicates to turn on the backlight function, select \" (NO) \"Means turn off the backlight, press \"SET\"Key to save and return to the setting project interface.

(NO) \"Means turn off the backlight, press \"SET\"Key to save and return to the setting project interface.

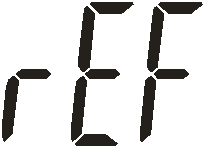

(REF) Sensor reference value: manufacturer reference value, users do not need to pay attention.

(REF) Sensor reference value: manufacturer reference value, users do not need to pay attention.

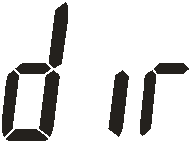

(dIr) Positive and negative push-pull direction: used to switch the positive and negative direction of the push-pull force gauge.

(dIr) Positive and negative push-pull direction: used to switch the positive and negative direction of the push-pull force gauge.

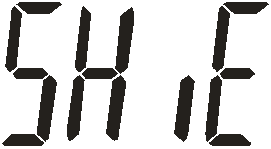

(SHIE) Cancel the shield: cancel the shield to display the full range1%The following data. press\"YES\"To not cancel, press \"NO\"Cancel.

(SHIE) Cancel the shield: cancel the shield to display the full range1%The following data. press\"YES\"To not cancel, press \"NO\"Cancel.

(R.SET) Factory reset function: under this setting item, press \"SET\"Key to restore the factory settings, the machine shut down. If you use the machine to restart.

(R.SET) Factory reset function: under this setting item, press \"SET\"Key to restore the factory settings, the machine shut down. If you use the machine to restart.

Nine, test

Press \"Power On \" to turn on the power, and use the factory default settings as needed to directly test or select the test mode to test.

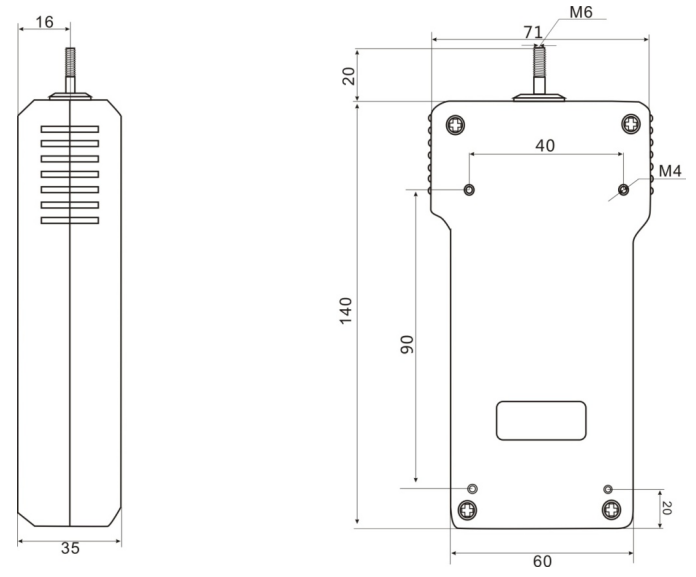

1. Select the appropriate test joint fixture to be installed on the push-pull force gauge (for self-made fixtures, please refer to the relevant data in \"Outline and Installation Dimensions \".

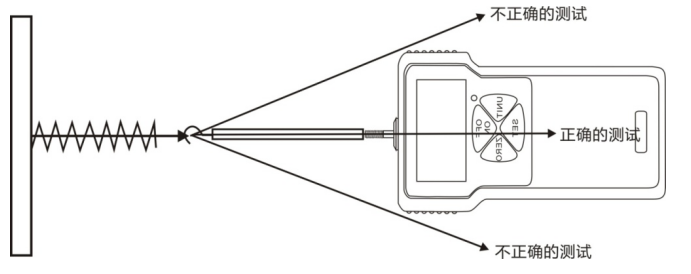

2. Please hold the push-pull force gauge firmly or install the push-pull force gauge on a suitable test machine for testing. During the test, please make the tested force and the push-pull rod of the push-pull force gauge in line to measure the accurate load .

3. After the test is completed, unload the load, turn off the power, remove the fixture, and clean the objects back into the tool box for the next use.

10. Safety precautions

1. Matters needing attention:

a. If you purchase this instrument, you need to charge it for 4 ~ 6 hours before it can be used normally.

b. If the operation is wrong, it may damage the instrument or cause serious accidents. This manual points out important matters for preventing accidents and how to use the instrument. Please read this manual carefully before use, and keep it properly after reading to prepare for reading here.

c. If the impact load is to be tested, please select the model whose maximum load is twice the impact load to be tested.

2. Warning matters:

a. During destructive testing, protective masks and gloves should be worn to prevent the splashed material from hurting the human body during the testing process.

b. Do not use damaged or severely bent fixtures. For self-made fixtures, please refer to the relevant parameters in this manual (the company also provides various fixtures, customers can choose according to need; purchase separately).

C. Do not use the instrument beyond the maximum range. Otherwise, the sensor may be damaged or even an accident may occur.

d. When the test value exceeds 100% of full scale, the buzzer will continue to sound. In this case, please quickly release the added load or reduce the load. When the test value exceeds 120% of full scale, the instrument may be damaged.

3. Solve the crash status: when the instrument crashes unexpectedly, use a small round rod with a hard object to press the\"reset\" button on the right of the instrument to quickly reset and shut down.

4. Safety matters:

a. Please use the matching charger to charge, otherwise it will cause circuit failure and even fire.

b. Do not use a power supply other than the rated voltage of the charger, otherwise it may cause electric shock or fire.

c. Do not pull out or insert the power supply with wet hands, otherwise it may cause electric shock.

d. Do not pull the power cord of the charger to pull out the plug, so as to avoid the electric cord being broken and being subjected to electric shock.

e. Please clean the machine with a soft cloth. Immerse the cloth in water soaked with detergent and wring it out to remove dust and dirt. Note: Do not use volatile chemicals to clean the machine (such as volatile agent, thinner, alcohol, etc.).

f. Do not operate the machine in the following environment

①Humid environment ②Dust environment ③Places where oil or chemicals are used ④Places with earthquake sources around

g. Please use and store within the specified temperature and humidity range, otherwise it may cause malfunction of the instrument.

h. Do not disassemble, repair or modify the machine by yourself, these actions may cause permanent failure of the instrument.

i. Other matters that need to be paid attention to in safety production.

J. Confirmation items before the push-pull force gauge is sent for repair

11. Appearance and installation dimensions

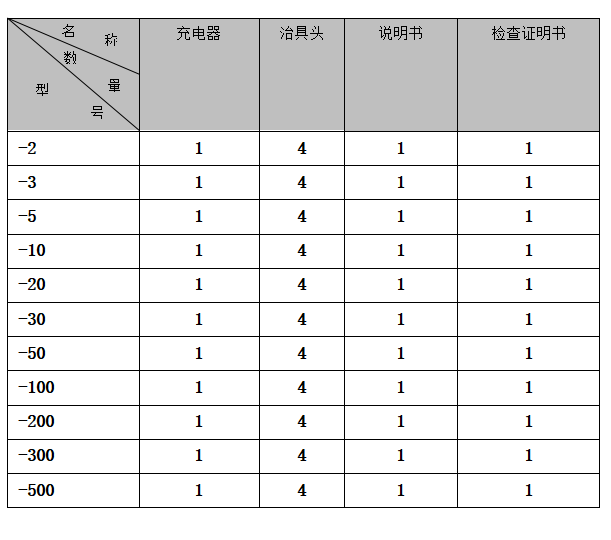

12. List of random attachments