One. Overview

The 50-ton electric horizontal hydraulic tester adopts a box frame structure, high-quality carbon structural steel material, single-rod double-acting piston cylinder to apply test force, pin-type link sample, load sensor force measurement, high-resolution meter data display . This machine is mainly suitable for tensile strength test of flexible parts such as steel wire rope, cable, hook, chain and so on.

2. Accessories for electric horizontal hydraulic tester

◆ 1 host;

◆ 1 set of electric hydraulic control system;

◆ 2 fixtures;

◆ 8 post supports;

◆ 1 high precision and high resolution digital display meter;

◆ One high-precision 100KN spoke tension sensor.

3. Main technical parameters

◆ Maximum test force: 500KN;

◆ Accuracy of test force: ± 1%;

◆ Measuring space 5000 mm;

◆ Horizontal measuring space 600 mm;

◆ Hydraulic station size: 1000 * 800 * 1100 mm;

◆ Piston stroke: 1000mm;

◆ Test speed: not less than 100mm / min;

◆ Force measuring method: load sensor measuring force;

◆ Overall dimensions of the host: about 7100 × 860 × 882mm (length × width × height)

◆ The weight of the whole machine is about 1200KG;

◆ Equipped with high-precision digital display push-pull force meter HF-10T;

◆ Maximum load 10T;

◆ Indication error ± 1% Scientific force range: 10-100% F · S;

◆ N (Newton), Kg (Kilogram), Ib (British Pound) three measurement units are available for selection and conversion;

◆ With peak hold, upper limit and lower limit settings, data storage function.

four. Instructions for use:

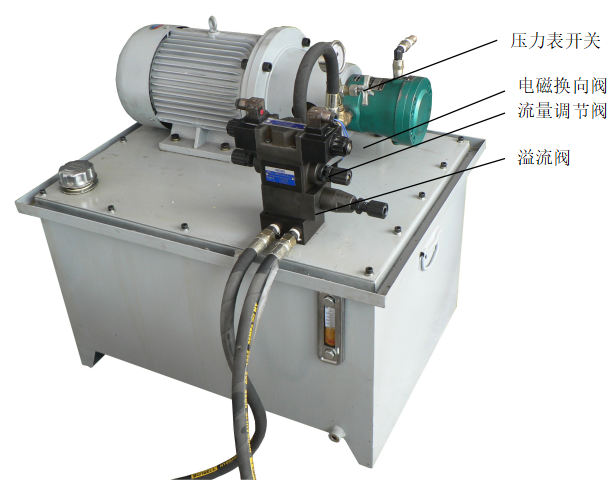

1. Pressure gauge switch: mainly used to cutBreak the connection between the pressure gauge and the oil circuit, or adjust the opening degree to prevent the pressure gauge from jumping rapidly and prevent damage. Under normal circumstances, it is normally open;

2. Electromagnetic directional valve: automatically control the direction of hydraulic oil in the oil circuit;

3. Flow regulating valve: used to adjust the flow rate, rotating clockwise decreases the flow, rotating counterclockwise increases the flow;

4. Overflow valve: It is used to adjust the pressure. Turning clockwise increases the pressure and turning counterclockwise decreases the pressure.

Five, matters needing attention:

1. The maximum pressure of this system is 31.5MPA, the capacity is 200L, the motor power is 5.5KW, and it is displayed on the nameplate;

2. 46 # anti-wear hydraulic oil must be selected before use, and the oil should reach the marked position of the liquid level gauge;

3. The use temperature is below 70 ℃, it may be best below 60 ℃;

4. It should be noted that no water can be mixed into the working oil, and oil from different manufacturers should also be avoided to be mixed; oil leakage should be controlled in every link;

5. The working oil should be checked once every three months. The new hydraulic oil that has begun to deteriorate will not prolong the service life, and should be replaced with new ones.

6. When the equipment starts to work, check whether the motor is running normally. If there is no sound of oil flowing, please check whether the motor is reversed;

7. This equipment adopts electric control mode to adjust the forward and backward work of the oil cylinder. The pressure can adjust the system pressure according to the force value of the object being pulled;

8. Due to the influence of voltage level or pressure during the operation of the equipment, the unstable sound of the equipment will be normal operation;

9. If you have any questions during use, please contact our technical department.

Other supporting instruments

|

equipment name |

model |

equipment name |

model |

|

Digital push-pull force gauge |

HF |

Electric vertical machine |

AEV |

|

Pointer push-pull force gauge |

NK |

Electric single column vertical machine |

AEL |

|

Digital torque tester |

ANL |

Electric horizontal machine |

AEH |

|

Bottle Cap Torque Tester |

ANL-P |

Spiral side roll test machine |

ASC |

|

Pointer torque screwdriver |

ANQ |

Manual horizontal test stand |

AMH |

|

High-speed impact torque tester |

AGN |

Manual vertical and horizontal test stand |

ASL |

|

Dynamic torque tester |

ADN |

Hand-pressed tensile and compression test stand |

AST |

|

Torque wrench tester |

ANJ |

Spiral tension and compression test stand |

ALX |

|

Torsion spring testing machine |

ANH |

Special testing machine for peeling force |

ABL |

|

Spring tension and compression testing machine |

ATH |

Ball pressure test device |

AQY |

|

Shore Rubber Hardness Tester |

LX |

Motorized hydraulic tension and compression test stand |

ALR |

|

Shore Hardness Test Stand |

LAC-J |

Button Tester |

ABQ |

|

Fruit Hardness Tester |

AGY |

Terminal tensile tester |

ADL |

|

Fruit Hardness Tester Stand |

GYJ |

Rope tension meter |

ASZ |

|

Tonometer |

ATN |

Side pressure tension tester |

HD |