Pointer Shore Hardness Tester Instructions

1. Performance Introduction

Pointer Shore hardness testers are widely used in hardness testing of vulcanized rubber and plastic products. It has the characteristics of simple structure, convenient use, small size, light weight and intuitive readings. It can be used for hand-held measurement. It can also be installed on the same type of Shore Durometer test stand of the same production for constant load test. Comply with standards DIN53505, ASTM D2240 ISO / R868, JIS R7215.

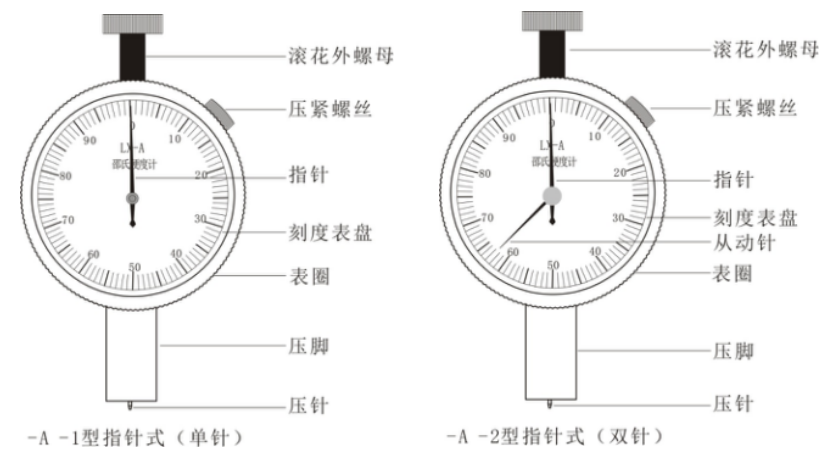

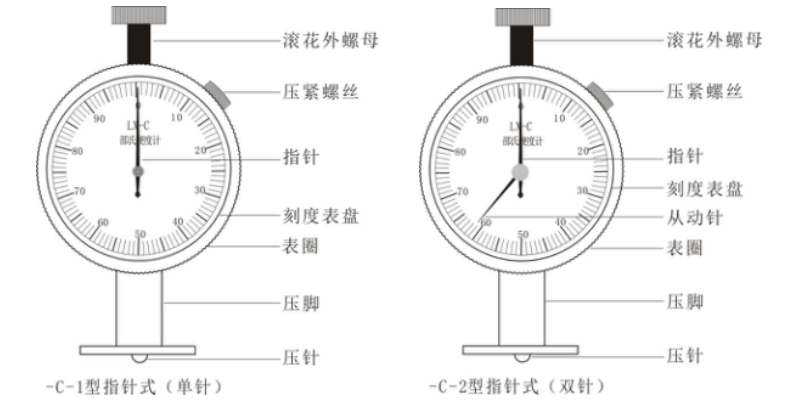

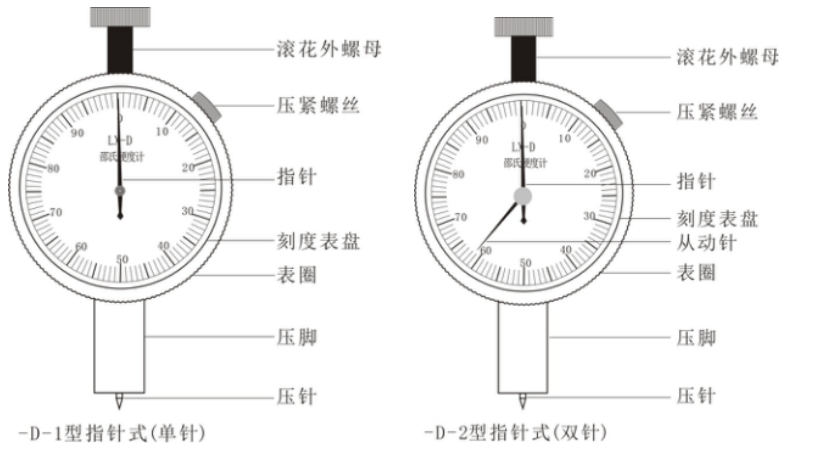

2. Type Appearance

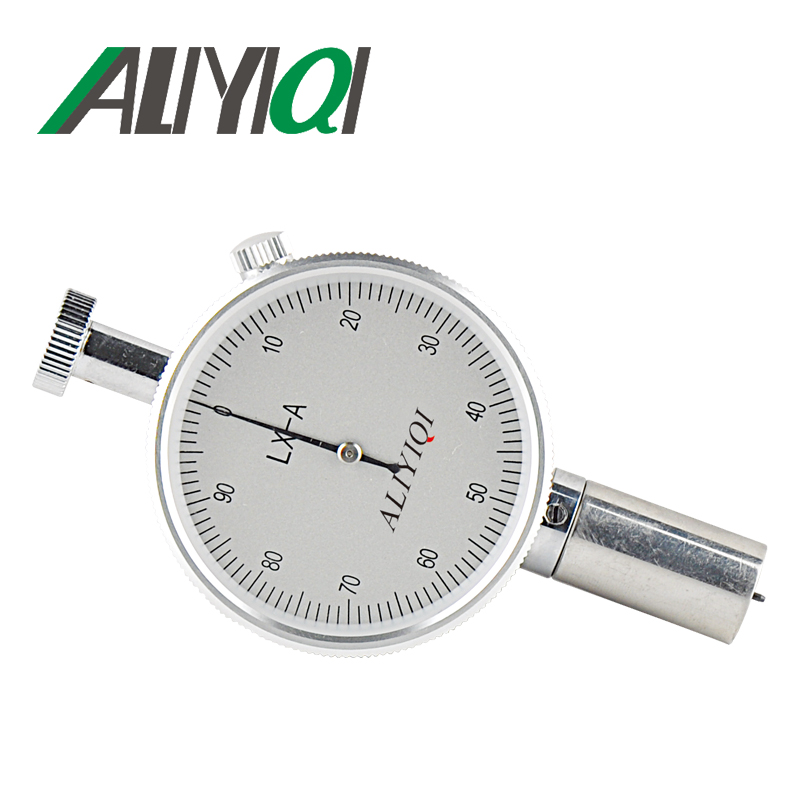

A pointer Shore hardness tester:

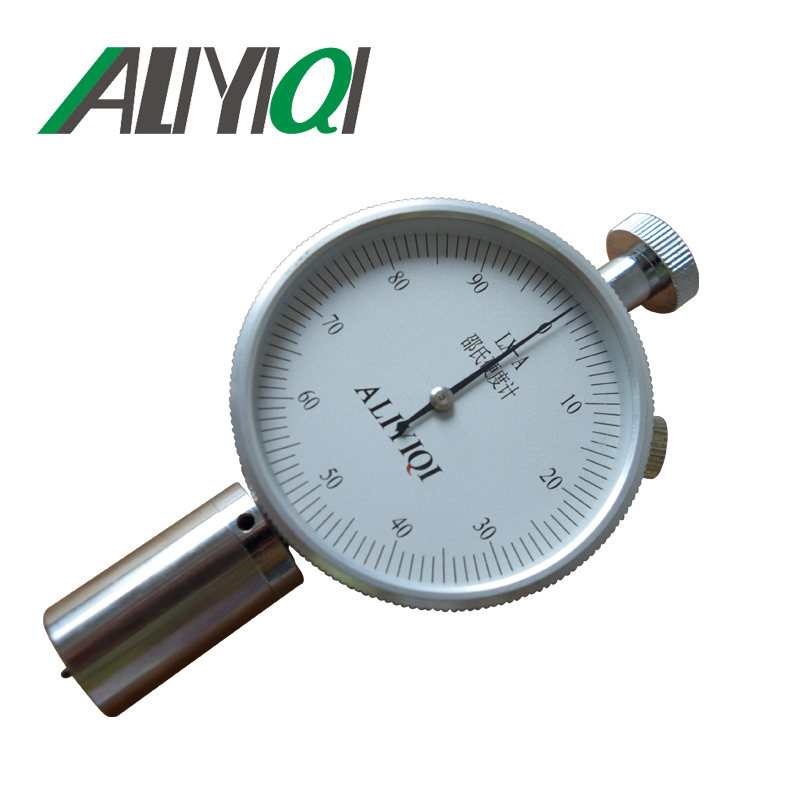

C Point Shore Hardness Tester:

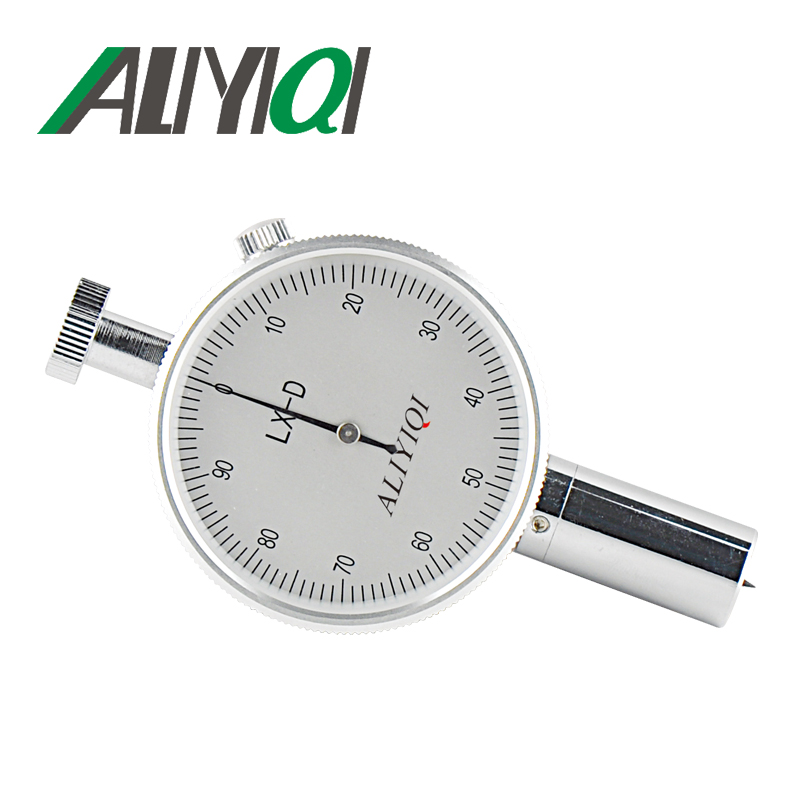

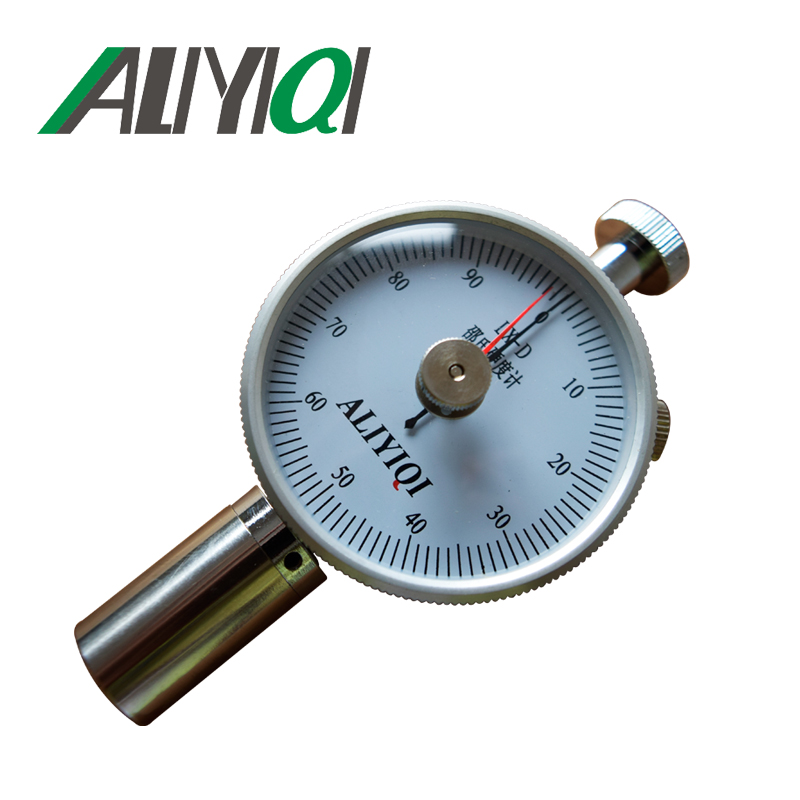

D Point Shore Hardness Tester:

3. Overview

Pointer Shore hardness tester has three types: A type, C type and D type.

Type A is generally suitable for testing the hardness of low-medium hardness materials such as rubber, synthetic rubber, polybasic grease, felt, leather, wax, etc.

Type C is suitable for the hardness testing of micro-porous materials for shoes similar to those made of rubber and plastics containing foaming agents with a compression rate of 50% and a stress of 0.049 MPa or more.

Type D is generally suitable for testing the hardness of high-hardness materials such as hard rubber, hard resin, organic glass, printed boards, floor materials, bowling balls and so on.

This hardness tester implements the relevant regulations of GB / T531-99, GB2411-80, HG / T2489-93, JJG304-2003, GBT 531.1-2008.

4. Main parameters

Dial value: 0-100 degrees

Needle stroke: 0-2.5mm

End pressure of pressing needle: A type, C type 0.55N-8.05N

D type 0-44.5N

5. How to use

Place the sample on a solid surface, hold the hardness tester and the panel of the hardness tester is at an angle with the operator, and press the needle at least 12mm away from the surface of the test sample. Press the hardness tester into the sample steadily until the presser foot and the sample are completely in contact, and the presser foot is completely in contact with the test sample within 1S. Each sample shall be tested no less than 5 times, and the distance between each test point shall be at least 6mm. After the test, take the average value (the distance between the measuring points of the microporous material is at least 15mm). In order to stabilize the test conditions and improve the test accuracy, the hardness tester should be installed on the Shore hardness tester matching with its model for testing. (Note: The double needle Shore hardness tester does not require a reading within 1S. After the double needle Shore hardness tester is tested, the driven needle will stay on the numerical scale of this test until the compression screw is turned to return to zero.)

6. Instructions for use

The pointer of the hardness tester should point to the zero position in a free state. If the pointer slightly deviates from the zero position, you can loosen the compression screw in the upper right corner and turn the bezel to align the hardness tester pointer to the zero position.

Press the hardness tester on the flat plate, and the end surface of the pressing pin is in close contact with the bottom surface of the presser foot. At this time, the pointer should be in the range of 100 ± 1 degrees. If the pointer is not at 100 ± 1 degrees, the hardness tester cannot be used.

Use method with the Shore Brinell test stand produced by the manufacturer: Remove the knurled outer nut on the head of the hardness tester and install it at the corresponding position of the test stand. Hold the handle down to pressurize the hardness tester under the weight of the weight, and its presser foot contacts the measuring platform on the test stand. At this time, the pointer of the hardness tester should be at 100 ± 1 degrees. If the pointer is not at 100 ± 1 degrees, the two adjustment handwheels of the test stand should be adjusted so that the hardness foot and the measuring platform are in full contact. After debugging, if the hardness count value still does not meet the standard, it can not be used, it is best to send the factory to adjust.

When checking the zero position of the D-type hardness tester, a special hard gauge block must be used for testing. If the glass plate is used for inspection directly, the hardness tester pressure pin will damage the surface of the glass plate, making the inspection value inaccurate. For the specific operation method, please refer to the instruction manual of the special gauge block.

Rubber samples should be prepared according to the requirements of GB / T631-99, plastic samples should be prepared according to the requirements of GB2411-80, and samples of rubber microporous materials should be prepared according to the requirements of GB2489-93.

If conditions permit, rubber samples should be adjusted at the laboratory standard temperature in accordance with the provisions of GB / T2941 and GB / T2918 before testing. When the sample is tested with the A-type hardness tester, if the measured value exceeds 90 degrees, it is recommended to use the D-type hardness tester; when the sample is tested with the D-type hardness tester, if the measured value is less than 20 degrees, it is recommended to use A type hardness tester is used for testing; when the A type hardness tester is used to test the sample, if the final measurement is less than 10 degrees, the measurement result is not accurate.

After the hardness tester is used, it should be wiped clean and placed in the instrument case, placed in a dry place to prevent moisture. The test bracket should be wiped frequently, and a small amount of anti-rust oil should be applied to prevent rust. In addition, No. 20 motor oil should be added to the active part. The hardness tester shall be submitted to the inspection regularly according to the provisions of JJG304-89.

Under the condition that the user abides by the product storage and use conditions, if it is due to the manufacture of the product and cannot work normally within 6 months from the date of purchase, our company is responsible for repairing and replacing the user for free.