Operating instructions of YGDW high and low temperature alternating damp heat test box

High and low temperature alternating heat and humidity test chamber

【Overview】

Features

The temperature controller of the high and low temperature alternating heat and humidity test chamber adopts the TH7110 series wide-screen panel LCD programmable temperature controller, which can be operated at a fixed value or a program, and the operation is simple and convenient. The refrigeration unit adopts French Taikang unit. The test box is equipped with a vacuum observation window with electrothermal coating, which can effectively solve the problem of condensation in the observation window. The test box adopts the overall integrated assembly structure, and the appearance is beautiful and elegant.

Main purpose and scope of application

The high and low temperature alternating humidity and heat test chamber is mainly used to test the temperature and humidity stress of the test piece, and can be used in aerospace, aviation, electronics, metallurgy, petroleum, chemical industry and other industries.

Basis and use standard

The design and manufacture of the test box meet the following test standards and methods

GB2423.1-89 Test A Low temperature test method

GB2423.2-89 Test A High temperature test method

GB / T2423.3-93 Test method for Ca constant humidity and heat

GB / T2423.4-93 Test Db alternating damp heat test method

GB2423.34-86 Test Z / AD temperature and humidity combined cycle test method

GJB150.3.4.9-89 High temperature test, low temperature test, damp heat test method

GB10586-89 Technical Conditions of Damp Heat Test Chamber

GB10592-89 high and low temperature test chamber technical conditions

2. 【Technical Parameters】

Temperature range: -40 ~ + 150 ℃

Studio size: 400 × 500 × 500 (mm) (depth × width × height)

Temperature uniformity: ≤2.0 ℃

Humidity Range: 20% ~ 98% R.H

Power source: AC220V, 50Hz

Power: 6kW

3. 【Structure characteristics and working principle】

The box body of this high and low temperature alternating humidity and heat test box adopts an integral structure. The inner plate is 1.0mm thick SUS304 stainless steel plate, the outer plate is 1.2mm thick cold-rolled steel plate, the surface is electrostatically powder coated, and the middle is filled with 100mm thick rock wool as an insulation layer.

The upper part of the test chamber is the working room, the right side is the electrical appliance control room; the lower part is the refrigeration unit, the lower right rear door is equipped with a water storage bucket for humidification, and a conductive film heating glass window is installed in the middle of the door to ensure that it can work under low temperature and high humidity Effectively observe the state of the test piece.

The control system of this high and low temperature alternating humidity and heat test chamber adopts Visuo TH7110 series wide-screen panel LCD display programmable temperature controller, PLC programmable controller and non-contact solid state relay, which can programmatically control the temperature and humidity of the test chamber, and Real-time paperless recording and storage of temperature and humidity test curves can be performed. (Up to 100 days)

The high and low temperature alternating heat and humidity test chamber has multiple safety protection functions:

Over-temperature protection function;

Water shortage protection function;

Compressor overload protector

Compressor overpressure protection.

4. [Installation and Use]

Turn on the external main power switch.

There is a display on the programmable controller screen.

The water tank at the bottom right of the tank is filled with distilled water.

Press Power \"On \", the screen of the meter lights up.

Set the temperature and humidity running program on the controller.

Press the\"Illumination\" switch when lighting is needed. (Do not turn on the lamp for a long time at high temperature)

When shutting down, first turn off the operation switch of the instrument, and then press the power button\"OFF\".

Fifth, the introduction of the temperature and humidity controller of Weishuo TH7110 color LCD touch screen

1. The 1000-segment mode can be executed (each step can be set with 1000 steps);

2. All repetitions: up to 999 times (infinite repetitions); partial repetitions: up to 99 times / programmatic connection;

3. Each segment can be set from 0 to 99 hours and 59 minutes;

4. Each set of settings can be part of the cycle of 1-499 times or all cycles of 1-499 times;

5. Microcomputer PID automatic check calculation and automatic adjustment function;

6. Can choose fixed value, program control;

7. The execution condition value can be arbitrarily changed when the fixed value is executed;

8. With over-temperature, fan overload and other alarm functions;

9. Memory type multi-function control, automatic adjustment of heating output;

10. The included recording function (and can store 100 days of historical data) can be analyzed, printed, and stored;

11. Equipped with one USB interface and one communication interface, which can be connected to a computer;

12. 8 points fault alarm input;

13. 10-point control output signal RUN / STOP.TS1-TS2;

14. Temperature upper limit deviation alarm TS1;

15. Absolute temperature upper limit alarm TS1—TS2;

16. Achieve high precision (0.1%) and high performance;

17. Operation screen display of auxiliary output state;

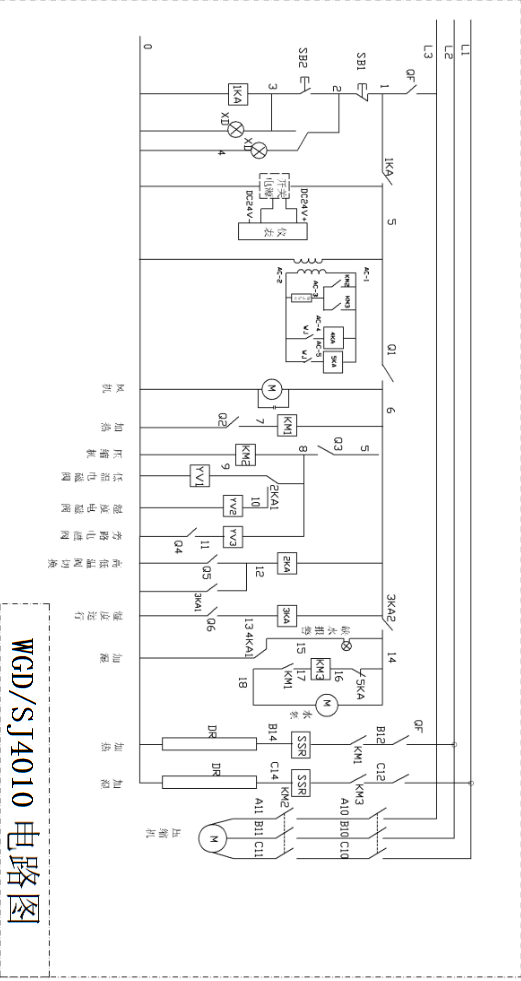

6. [Electrical Circuit Diagram]

7. [Notes]

The electrical control box should be reliably grounded.

After the equipment is powered on, it is strictly forbidden to carry out maintenance on power, and do not approach the electrical control box.

Those who are not qualified for operation are strictly prohibited from starting and operating.

It is strictly forbidden for other equipment to share an air protection switch with this equipment.

It is strictly forbidden for those who are not qualified to repair to repair the equipment.

Collisions are strictly prohibited.

Do not touch the control instrument with sharp objects.

It is strictly forbidden to wipe the control cabinet with corrosive cleaning fluid.

In order to exert the function and performance of the test chamber stably, the place with a temperature of 10 ℃ ~ 30 ℃ and a relative humidity of <85% should be selected.

Avoid sudden changes in the ambient temperature of the installation site.

It should be installed on a level ground (a level should be used to determine the level on the ground during installation)

It should be installed in a place without direct sunlight.

It should be installed in a well-ventilated place.

It should be installed in a place away from combustibles, explosives and high-temperature heat sources.

8. [Random Attachment]

|

No. |

Name |

Quantity |

Remarks |

|

1 |

file |

1 serving |

Operating Instructions |

|

2 |

Accessories |

2 sets |

Experiment stand |

Nine, [simple troubleshooting method]

|

Fault phenomenon |

the reason |

elimination method |

|

No heating |

Failure of the electric heating wire |

Replace the heating wire |

|

Heating circuit fuse blown |

Replace the fuse |

|

|

Temperature control instrument parameter setting error |

Set the temperature control instrument parameters to the correct value (see the manual for details) |

|

|

Damaged temperature control instrument |

Repair or replace |

|

|

Temperature control instrument over-temperature setting is lower than required |

Modify the over-temperature parameters of temperature control instrument |

|

|

Solid state relay damaged |

Replace solid state relay |

|

|

Contactor damaged |

Replace the contactor |

|

|

Temperature is not displayed |

Bad sensor |

Replace the sensor |

|

Temperature control instrument wiring is off |

Tighten the wiring |

|

|

The temperature control instrument is set incorrectly |

Set according to factory data |

|

|

Bad temperature control instrument |

Replace the temperature control instrument |

10. [Quality Assurance]

Under the premise of following the user manual of the product, if a product failure occurs, the company will implement a one-year product quality guarantee period from the date of product leaving the factory, and perform free maintenance on the product.

When the product quality guarantee period is exceeded, the company will continue to provide maintenance services for users and charge fees as appropriate.

In case of failure, please contact our company in time, we will guide the user how to eliminate the failure as soon as possible after receiving the phone or fax. If necessary, the company will send service personnel to the scene within 24 hours to troubleshoot.

|

Warranty registration card |

|

|

Product number |

|

|

device ID |

|

|

Purchase time |

|

|

warranty period |

One year |

Warranty description:

This service warranty card is Chixuan Test Equipment (Shanghai) Co., Ltd., and the products it sells provide free after-sales service certificates.

The warranty period starts from the acceptance date and provides one-year free after-sales service.

During the warranty period, the company provides free maintenance services, but in the following cases, although within the limited warranty period, you must also charge technical or material fees:

Damaged by natural disasters.

Failure due to user's fault or operation error.

Improper use of the power supply voltage causes damage.

Self-repair and damage.

Lend it to others for malfunction.

Refit yourself to cause a malfunction.

Correct yourself to cause a malfunction.

Failure to transfer or transport carelessly.

Services in remote areas.

If this warranty card is lost, the company will not reissue it, please keep it properly.

Thank you for using our products. If there is any unclear use, please contact our service personnel. Our company will do our best to provide you with the most complete service.

Certificate of conformity

Product name: High and low temperature alternating damp heat test box

Product model: YGDW

Factory number: XC18

According to the inspection results, the product is qualified and approved for delivery.

Quality inspector:

Inspection Date: 2018 Month Day