1. Applicable occasions

ASZ type rope tension meter is suitable for power industry, communication industry, transportation industry, glass wall curtain decoration industry, ropeway operation industry, construction industry, playground, tunnel construction, fishery fishing and major scientific research institutes and teaching institutions, testing institutions And occasions involving the pulling force of rope and wire rope.

2. Features

1. The rope structure with tension, can be measured directly without disassembly.

2. Light weight, simple structure and convenient operation, suitable for any occasion.

3. Stable performance, high measurement accuracy, with automatic system compensation function, when the measured cable specification is the same as the dynamometer cable specification, the accuracy can reach within 2% within the rated range.

4. It has fifteen kinds of wire diameter measurement functions and a wider measurement range.

5. Scope of application: suitable for flexible, stretched cables. Such as various steel wire ropes, high-strength ropes, etc.

6. Accuracy level: 2 ~ 6% of MAX function (depending on the rope form and characteristics).

7. Rope diameter: ¢ 6 ~ ¢ 40mm.

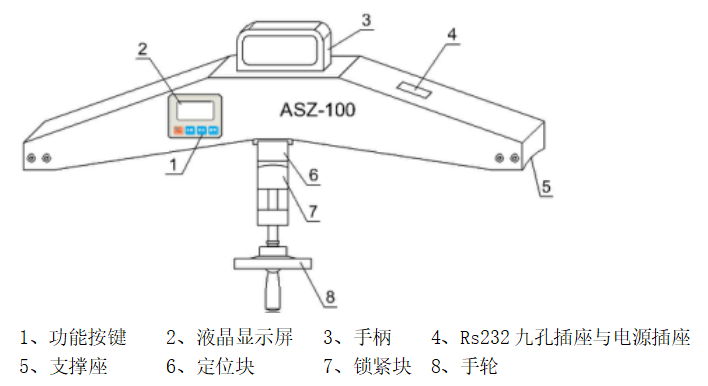

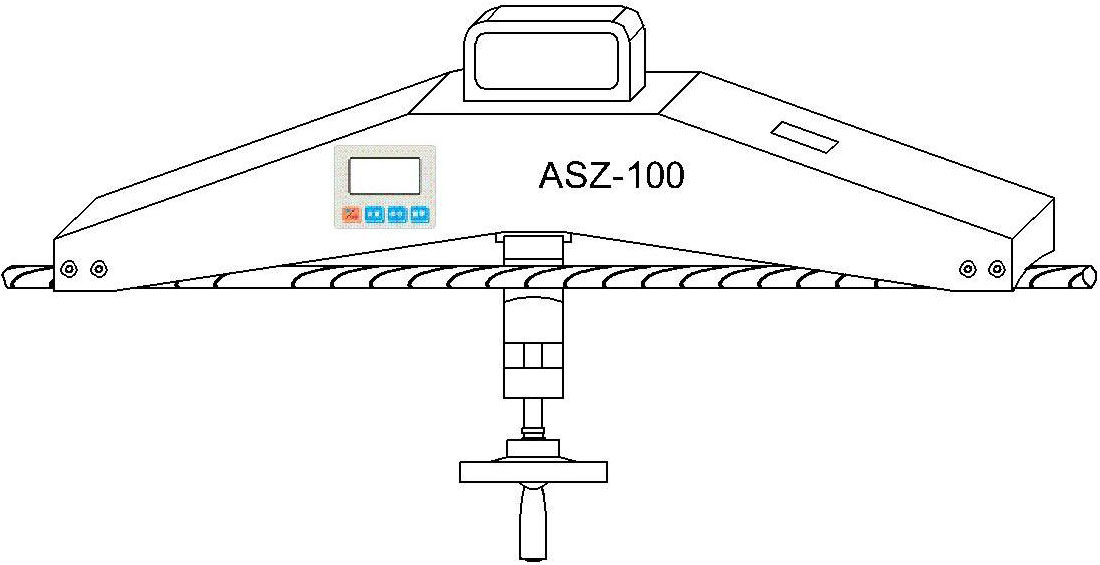

3. Shape and structure

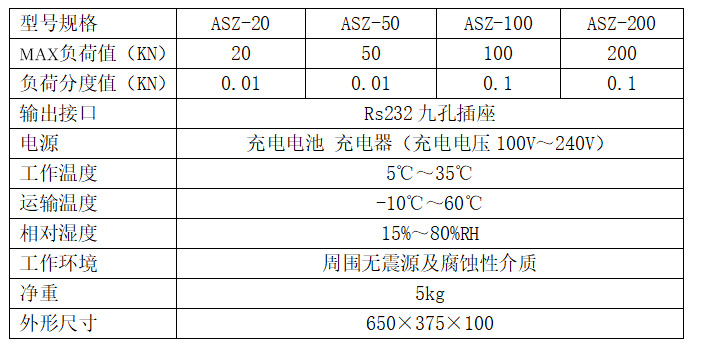

4. Model specifications

5. Working principle

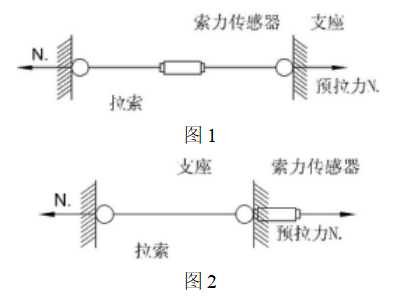

The determination of cable force is divided into two types: interventional and non-interventional. The so-called interventional force measurement refers to connecting a tension sensor in series at the end or span of the cable, and directly reading the cable force. This is the most accurate and intuitive force measurement method, as shown below 1, 2 shows.

The input of this force measurement method is large, and it is only suitable for experimental research and individual projects with large tonnage and high requirements. It is not suitable for prestressed structural projects with large amount of cable.

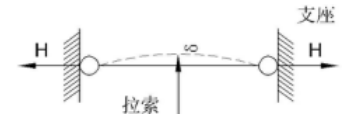

There are also two methods of non-intrusive force measurement. One is the vibration frequency measurement method, that is, the natural vibration period T of the cable is a function of the tension H, the length L of the cable, and the mass W of the cable. From the formula, the measured The cable's vibration period T can calculate the tensile force H in the cable. The principle is relatively simple, but the seismic signal is converted into a signal, and the cable force value is output after being processed by the computer. This process requires many instruments and equipment, which makes it difficult for workers to master, and is not convenient for working at heights. In addition, the supporting conditions of the cable end have an impact on the vibration period and the accuracy of the cable force measurement. Another principle for measuring the cable force is based on mechanical principles. As shown in the figure below, there is a functional relationship between the lateral displacement δ of the cable force and the tensile force H, lateral force P of the cable and the length of the cable. When the displacement maintains a certain value, the greater the cable tension H, the greater the lateral force P.

The force sensor outputs the lateral force P, which is converted into cable tension after being processed by the microprocessor, and then displayed on the LCD. The above principle is also relatively simple, but the relationship between the lateral force and the cable force is still related to the diameter of the cable, the cross-sectional structure. The elongation of the rope and the size of the tensile force, etc. We use the correction and accurate calibration of the microprocessor After getting the correct and stable cable. Can pass the test and inspection, has reached the level of similar foreign products.

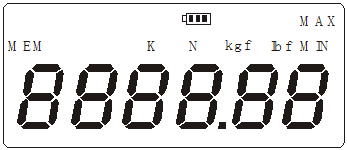

Six, screen display

1. PEAK display

When \"PEAK \" is displayed, it indicates Peak mode (peak holding mode), the display shows the peak until manually cleared; when \"PEAK \" is not displayed, it means \"track mode \" (real-time load value mode) , The value on the screen changes with the load.

2. MEM display

When data is stored in memory, \"MEM \" will be displayed. When you press \"Save \" to view the memory data, \"MEM \" flashes.

3. Unit display

The letters \"K \" are combined with \"N \", \"kgf \", \"lbf \" to form \"KN (thousand of cattle) \", \"t (tons) \", \"Klb (Thousand pounds) \"As shown:

4. MAX, MIN display

When the measured value is greater than the MAX value, MAX is displayed;

When the measured value is less than the MIN value, MIN is displayed.

1. Power display

Power display And low battery tips.

And low battery tips.

Seven, key introduction

1. ON / OFF key: can be used to turn on and off.

2. Setting key: the user can enter the setting menu through this key in the measurement interface, and press this key to save the data when setting the data.

3. Save key: used to save the measured data, long press this key to enter the view interface. When viewing the interface, press this key to select the currently stored measurement value.

4. Zero setting key: during real-time measurement, press this key to correct the zero point. During peak and auto peak, press this key to clear the peak and return to zero; when viewing the interface, press this key to clear the currently stored measurement value, long press this key to clear all stored measurement values. In the user setting interface, press this key to return to the previous interface without saving data.

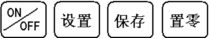

Eight, boot display

Nine, function introduction

1. Setting function

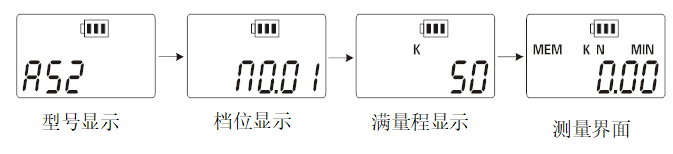

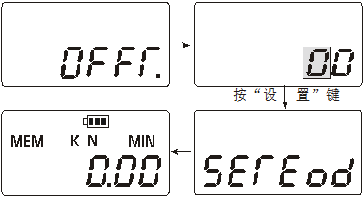

a. Unit setting: After the start-up display is completed, press \"Settings \" to enter the unit setting, and press \"Set Zero \" once to switch between N, kg, and Ib units, and select the desired unit. , And then press \"Settings \" to enter the next function setting, as shown in the figure below:

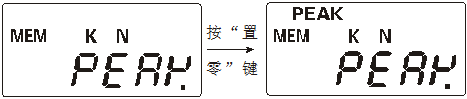

b. Peak setting: After the previous operation is completed, press \"Settings\" to enter the peak setting, and press \"Zero \" once to perform PEAK (indicating peak hold mode), no such character display (indicating real time Load value mode) Switch between the two modes, select the desired mode, and then press \"Settings \" to enter the next function setting, as shown in the following figure:

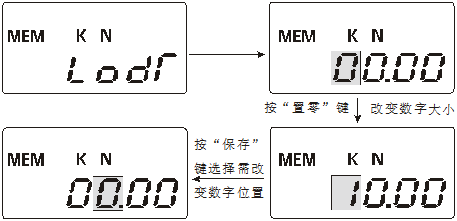

c. Limit setting: After the previous operation is completed, press \"Settings \" to enter the lower limit setting, press \"Save \" and \"Zero \" keys to adjust the numbers and select the desired value, Press \"Settings \" again to enter the next function setting, as shown below:

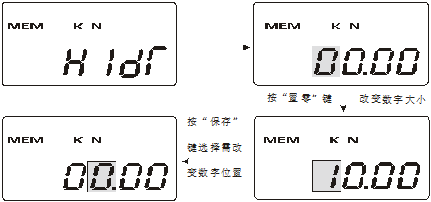

d. Upper limit value setting: After the previous operation is completed, press \"Settings \" to enter the upper limit value setting, respectively press \"Save \", \"Zero \" to adjust the numbers and select the desired value , And then press \"Settings \" to enter the next function setting, as shown in the figure below:

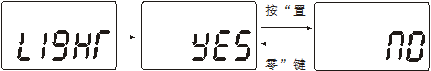

e. Backlight function setting: After the previous operation is completed, press \"Settings \" key to enter the backlight function setting, and press \"Zero \" key once to switch between YES and NO modes, select the required Mode, then press \"Settings \" to enter the next function setting, as shown in the figure below:

f. Automatic shutdown time setting: After the previous operation is completed, press \"Settings \" to enter the automatic shutdown time setting. Press \"Save \" and \"Zero \" keys to adjust the numbers and select the desired value. , And then press \"Settings \" key to display the setting completed interface, and then return to the measurement mode, as shown in the following figure:

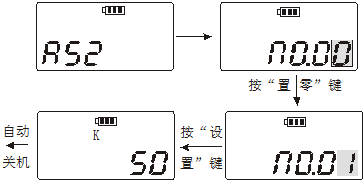

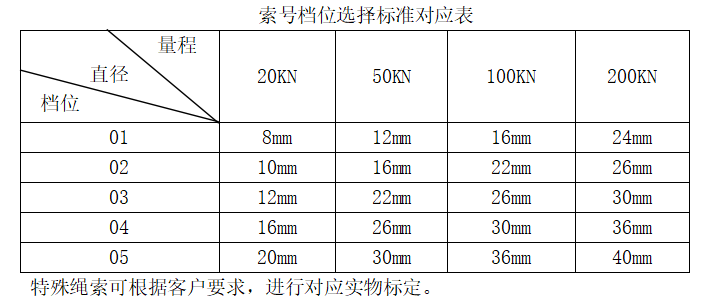

2. Selection of number slot

After booting, press and hold \"Save \" key to enter the gear selection, press \"Zero \" key to select the gear, and then press \"Settings \" key, the system saves the data, automatically shuts down, restarts after shutdown, as follows The picture shows:

3. Save function

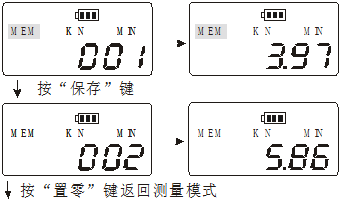

a. Under the normal measurement state, press the \"Save \" key to save a measurement value obtained while testing;

b. Press and hold the\"Save\" button for 4 seconds to enter the view interface. The \"MEM \" character flashes on the interface to view the stored data. Then press the\"Save \" key to view the next set of data and press \ Press the\"Zero \" key to return to the measurement mode, as shown in the following figure:

10. How to use

1. According to the outer diameter of the tested rope, select the cable number gear. (For the specific key operation, please refer to the second point of the function introduction above)

Note: During the test, align the highest point of the rope with the positioning block, and press the tested rope tightly on the positioning block.

Loosen the locking handle, the tested rope passes between the locking block and the positioning block, the two support bases are in full contact with the rope, as shown in the figure below, press \"Zero \" to select the measurement mode (real-time load value mode Peak hold mode, peak hold automatic release mode).

2. Tighten the locking handle and press the tested rope against the positioning block. The displayed value is the actual tension of the tested rope.

11. Safety Precautions

Precautions

Incorrect operation may damage the instrument or cause serious accidents. This manual points out important matters for preventing accidents and how to use the instrument. Please read this manual carefully before use, and keep it properly after reading, so that you can read it again.

If you are testing the impact load, please select the model whose MAX load is twice the impact load to be tested.

Warning matters

1. Do not use the instrument beyond the MAX range. Otherwise, the sensor may be damaged or even an accident may occur.

2. When the test value exceeds the range, the buzzer will beep continuously, at this time, please quickly release the added load or reduce the load.

Safety Precautions

1. Please use the matching charger to charge, otherwise it will cause circuit failure and even fire.

2. Do not use a power supply other than the rated voltage of the charger, otherwise it may cause electric shock or fire.

3. Do not pull out or insert the plug with wet hands, otherwise it may cause electric shock.

4. Do not pull the plug of the charger's power cord to pull out the plug, so as to prevent the cord from being broken and being shocked.

5. Please clean the machine with a soft cloth. Immerse the cloth in water soaked with detergent and wring it out to remove dust and dirt.

Note: Do not use volatile chemicals to clean the machine (such as volatile agent, thinner, alcohol, etc.)

6. Do not operate the machine in the following environment

(1) Humid environment (2) Dusty environment

(3) Places where oil or chemicals are used (4) Places with vibrators around

7. Please use and store within the specified temperature and humidity range, otherwise it may cause instrument failure.

8. Do not dismantle, repair or modify the machine by yourself, these actions may cause instrument failure.

9. Other matters that need to be paid attention to in safety production.

Other supporting instruments

|

equipment name |

model |

equipment name |

model |

|

Digital push-pull force gauge |

HF |

Electric vertical machine |

AEV |

|

Pointer push-pull force gauge |

NK |

Electric single column vertical machine |

AEL |

|

Digital torque tester |

ANL |

Electric horizontal machine |

AEH |

|

Bottle Cap Torque Tester |

ANL-P |

Spiral side roll test machine |

ASC |

|

Pointer torque screwdriver |

ANQ |

Manual horizontal test stand |

AMH |

|

High-speed impact torque tester |

AGN |

Manual vertical and horizontal test stand |

ASL |

|

Dynamic torque tester |

AND |

Hand-pressed tensile and compression test stand |

AST |

|

Torque wrench tester |

ANJ |

Spiral tension and compression test stand |

ALX |

|

Torsion spring testing machine |

ANH |

Special testing machine for peeling force |

ABL |

|

Spring tension and compression testing machine |

ATH |

Ball pressure test device |

AQY |

|

Shore Rubber Hardness Tester |

LX |

Motorized hydraulic tension and compression test stand |

ALR |

|

Shore Hardness Test Stand |

LAC-J |

Button Tester |

ABQ |

|

Fruit Hardness Tester |

AGY |

Terminal tensile tester |

ADL |

|

Fruit Hardness Tester Stand |

GYJ |

Rope tension meter |

ASZ |

|

Tonometer |

ATN |

Side pressure tension tester |

HD |