I. Overview

1.1 Main uses and scope of application

AZGH-G series rope tension meter is an online instrument for measuring the tension of wires, cables, optical fibers and ropes. Used for tension measurement. It is also suitable for major scientific research institutions, testing institutions and other occasions.

1.2 Product Features

1.2.1 Online measurement: The rope does not need to be disassembled when measuring the rope. The rope with tension can be measured online. When the rope tension is loaded in real time, the real-time tension can be observed online.

1.2.2 Portable: The instrument adopts high-strength aluminum alloy structure, light weight, small volume, and easy to carry. When measuring the tension of the rope, one person can complete all operations.

1.2.3 Convenient operation: The loading mechanism of the instrument adopts a lever structure, which only needs to push the handle of the instrument to measure the rope tension correctly; the operation is simple, and one person can complete a measurement within 30 seconds.

1.2.4 The performance of the instrument is stable and the measurement accuracy is high. When the rope size to be tested is consistent with the rope number stored in the dynamometer, the measurement accuracy can reach 5% within the quantifiable range.

1.2.5 The instrument has 3 kinds of preset specifications ropes, you only need to select the corresponding rope number when measuring.

1.2.6 Digital display shows the force value, the instrument uses LCD to display the measured force value, the reading is more convenient.

1.2.7 Three unit switch: The instrument can switch N, KSf and Lbf three force values.

1.2.8 The instrument can save 383 sets of measurement data, and the saved data can be exported by computer.

1.3 Varieties and specifications

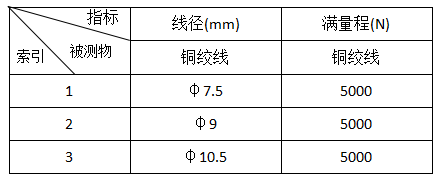

1.3.1 The built-in specifications of AZGH-A-5000G rope tension meter are as follows:

1.4 Product technical parameters

1.4.1 Division value: 1N

1.4.2 Accuracy: ± 5%

1.4.3 Power supply: 7.2V Ni-MH battery pack

1.4.4 Charger: input AC 100 ~ 240V 50Hz output: DC 12V 500mA

1.4.5 Sampling rate: 10Hz

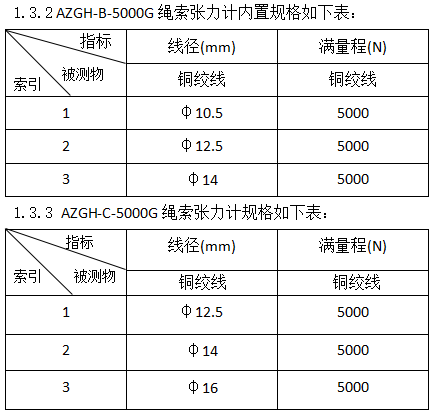

1.5 Model composition and its representative meaning

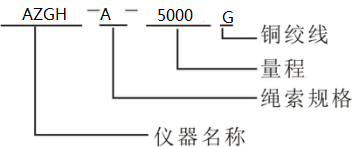

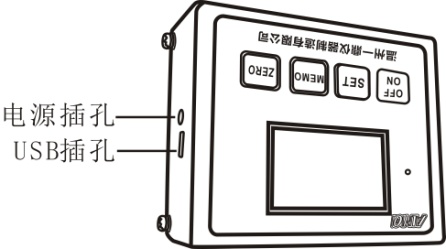

Second, the overall product structure

2.1 Overall structure

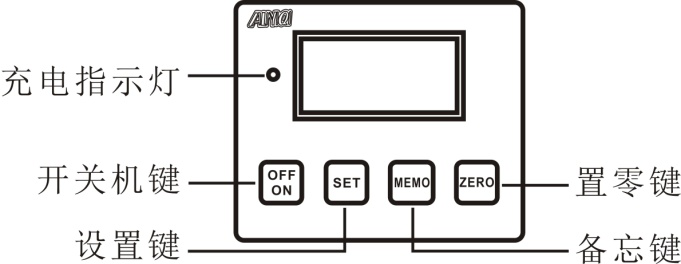

2.2 LCD screen function

2.2.1 Power on / off key: When this key is pressed, the power is turned on or off.

2.2.2 Setting key: the user can enter the setting interface through this key during the measurement interface, and press this key to save the data when setting the data.

2.2.3 Memo key: There is a function to save the measurement data in the measurement interface; long press this key in the measurement interface to view the saved data; when entering the setting interface, it has an up function.

2.2.4 Zero setting key: In the measurement interface, press this key, the test value on the screen will be reset to zero. When setting data, press this key to return to the setting interface.

2.2.5 Charging indicator: When plugging in the charging power supply, the red light will be displayed when the power supply is not full, and the green light will be displayed when it is full.

3. Use and operation

3.1 Preparation and inspection before use

3.1.1 Check the power, if it is insufficient, it needs to be charged before use.

3.2 Operation and instructions in use

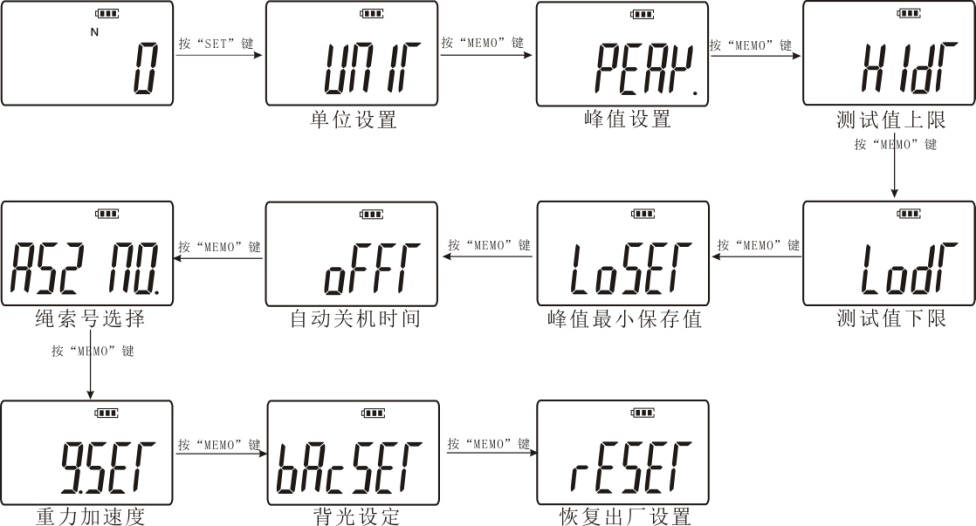

3.2.1 Setting items

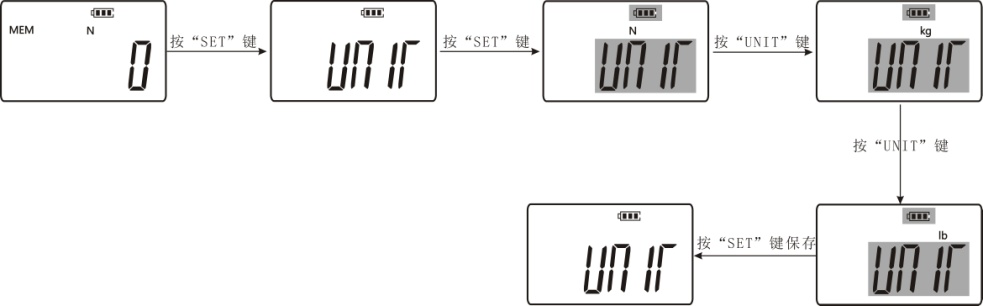

3.2.2 Unit setting: After power on, enter the measurement interface, press \"SET \" to enter the setting interface, press \"SET \" again to enter the unit setting, press \"MEMO \" to select the unit, After saving the required units, press \"SET \" to save and exit to the setting interface. As shown below:

3.2.3 Peak setting: After the previous operation is completed, press \"MEMO \" to select \"PEAK \", after entering, press \"MEMO \" in \"PEAK \" (peak mode), no such character is displayed ( Indicates the real-time load value mode) Switch between the two modes, select the desired mode, then press \"SET \" to save and enter the next function setting, as shown in the following figure:

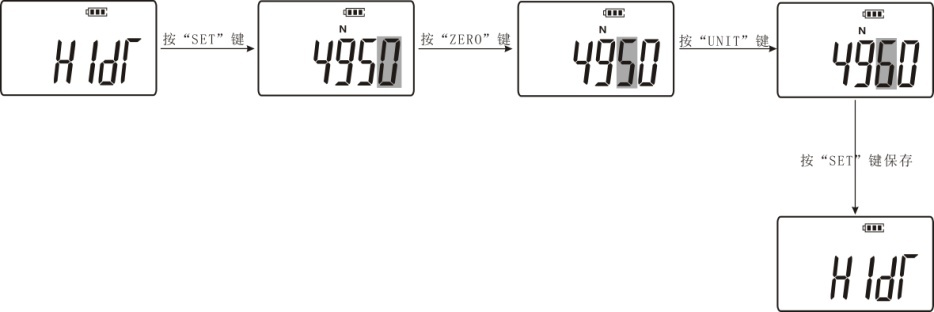

3.2.4 Upper limit value setting: Press \"SET \" key to enter the upper limit value setting, press \"ZERO \" key and \"MEMO \" key to perform digital adjustment, select the desired value, then press \"SET \"Key to save and enter the next function settings, as shown in the following figure:

3.2.5 Lower limit value setting: Press \"SET \" key to enter the lower limit value setting, press \"ZERO \" key and \"MEMO \" key to adjust the numbers, select the desired value, then press \"SET \"Key to save and enter the next function settings.

3.2.6 Peak minimum saved value: In peak mode, when the current value is less than this value, the peak value will not be saved. Press \"SET \" to enter the setting of the minimum stored value of the peak value, press \"ZERO \" and \"MEMO \" to adjust the numbers, select the desired value, then press \"SET \" to save and enter the next step Function settings.

3.2.7 Automatic shutdown time setting: It can be set to shut down automatically from 1 minute to 9999 minutes, or it can be set to\"0000\" to not shut down. The machine is set to 30 minutes by default. Press \"SET \" to enter the automatic shutdown time setting, press \"ZERO \" and \"MEMO \" to adjust the numbers, select the desired value, then press \"SET \" to save and enter the next function Settings.

3.2.8 Selection of file number: Press \"SET \" to enter \"Cable number file selection \" settings, press \"MEMO \" to select the desired file, press \"SET \" to save, the instrument Automatic shutdown, just restart.

3.2.9 Gravity acceleration setting: The user can set the gravity acceleration value according to the location of the area, the default value is 9.800.

3.2.10 Backlight function setting: Under this setting item, use \"MEMO \" key to select, if you select \"YES \" to turn on the backlight function, choose \"NO \" to turn off the backlight, press \ The\"SET \" key saves and returns to the setting item interface.

3.2.11 Restore factory settings function: Under this setting item, press \"SET \" key to restore the factory settings, the machine shuts down. If you use the machine to restart the machine.

3.3 Test

3.3.1 Turn on the switch.

3.3.2 According to the outer diameter of the tested rope, select the cable number gear. (Refer to the specification table above)

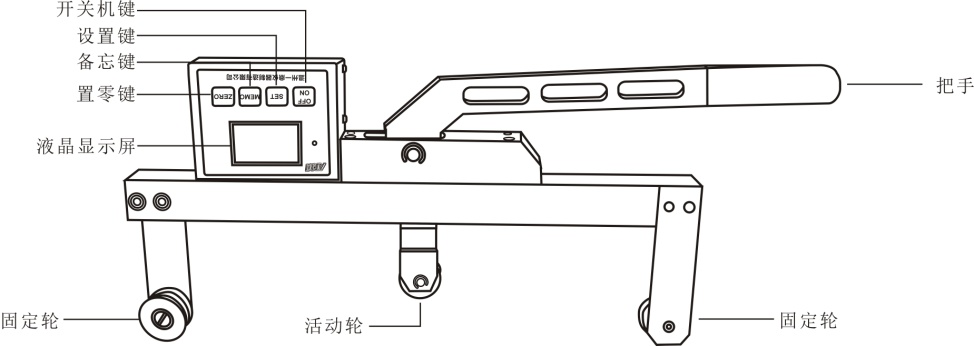

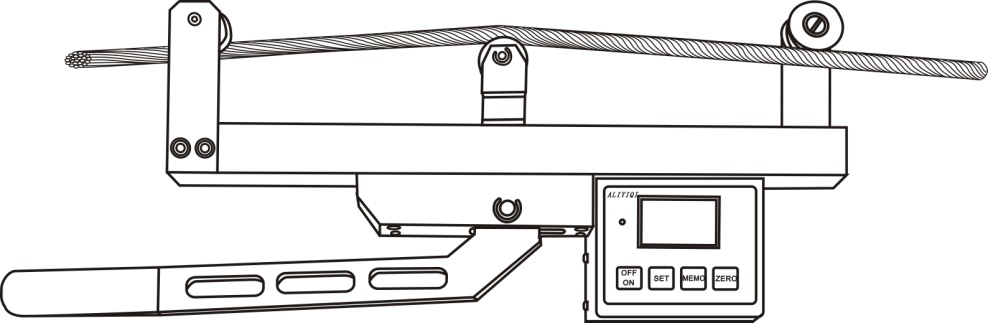

3.3.3 Pass the tested rope through the movable wheel, and the two fixed wheels are in full contact with the rope, as shown in the following figure:

3.3.4 Press the tested rope tightly on the movable wheel, tighten the handle, and the displayed value is the actual tension force value of the tested rope.

3.4 Export of saved data

3.4.1 Store data

Press \"MEMO \" to save the data. When no data is saved, there is no display on the display. When data is saved, MEM is displayed. When you press and hold \"MEMO \" to view the saved data, \"MEM \" flashes, the number of saves appears first, and the saved value automatically appears after 2 seconds. Press \"ZERO \" to exit the view interface and enter the test directly. Data can also be input into a computer for analysis and processing. This machine can store 383 sets of data. When more than 383 sets of data, the subsequent data will not be saved.

Four, maintenance and warranty

4.1 Routine maintenance and maintenance

4.1.1 Please use the matching charger to charge, otherwise it will cause circuit failure and even fire.

4.1.2 Do not use a power supply other than the rated voltage of the charger, otherwise it may cause electric shock or fire.

4.1.3 Do not pull out or insert the plug with wet hands, otherwise it may cause electric shock.

4.1.4 Do not pull the plug of the charger's power cord to pull out the plug, so as to avoid the electric cord being cut off and being subjected to electric shock.

4.1.5 Please use a soft cloth to clean the machine. Immerse the cloth in water soaked with detergent and wring it out to remove dust and dirt.

Note: Do not use volatile chemicals to clean the machine (such as volatile agent, thinner, alcohol, etc.)

4.2 Maintenance during operation

4.2.1 Do not use the instrument beyond the maximum range. Otherwise, the sensor may be damaged or even an accident may occur.

4.2.2 When the test value exceeds the range, the buzzer will beep continuously. At this time, please quickly release the added load or reduce the load.

4.3 Maintenance and care during long-term shutdown

4.3.1 Please use and store within the specified temperature and humidity range, otherwise it may cause instrument failure.

Five, packing list

|

1 |

AZGH-G Rope Tensiometer |

1 |

|

2 |

12V charger |

1 |

|

3 |

Instructions |

1 serving |

|

4 |

Certificate of conformity |

1 piece |

|

5 |

Desiccant |

1 package |

|

6 |

Inspection certificate |

1 serving |

|

7 |

Data cable |

1 |