The elevator rope tension meter is mainly used for the tension test of elevator traction wire rope. In the process of elevator installation, acceptance and annual inspection, the tension of each traction wire rope is tested and adjusted to make it as consistent as possible, so as to extend the life of the traction wheel and make the elevator wire rope run more smoothly. The tensiometer can also be used for bridge slings, pole and tower wiring, overhead wires, index wire ropes and other tests involving steel cable tension.

1. Features:

1. High precision and high resolution, 6-bit large screen display;

2. Three display modes are available-to maximize the test efficiency;

3. N (Newton), kg (Kilogram), lb (Pound) three measurement units are available for selection and conversion;

4. Peak hold function. Keep peak display until manually cleared;

5. Automatic peak function, keep displaying the peak value and automatically release after 3 seconds;

7. The upper and lower limits and comparison values can be set for statistical analysis. Buzzer alarm when the comparison value is exceeded;

8. Data storage function, can store 896 test values;

9. Data output function, the data can be input into the computer through the data line for various analysis;

10. Green and environmental protection, automatic shutdown after 50 minutes of no operation.

11. High-quality charging power supply. The charging voltage is available from 100V to 240V, which can be adapted to most areas at home and abroad. There are short circuit, leakage, overload protection functions;

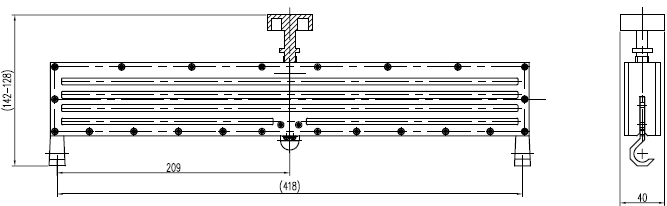

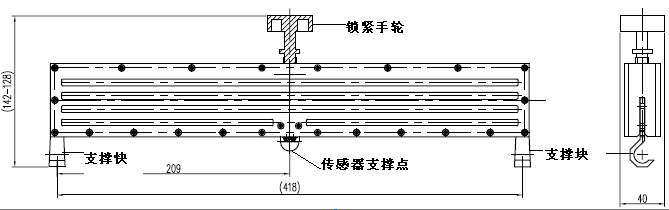

Second, the structural dimensions of the sensor bearing body are shown in Table 1, and the instrument model specifications are shown in Table 2.

1. Dimension drawing of sensing bearing body

2. Instrument specifications

|

model |

300 |

500 |

1000 |

3000 |

5000 |

|

Range |

300N |

500N |

1000N |

3000N |

5000N |

|

Resolution |

0.1N |

1N |

|||

|

Recommended measuring range |

10% -90% |

||||

|

Accuracy |

≦ ± 5% |

||||

|

Rope diameter |

φ15mm (φ8 ~ φ14mm need to be customized) |

||||

|

Loading method |

Manual |

||||

|

power supply |

7.2V Ni-MH rechargeable battery pack |

||||

|

Dimensions |

Bearing body: 418 × 128 × 40mm Host machine: 230 × 66 × 36mm |

||||

|

weight |

1.37kg |

||||

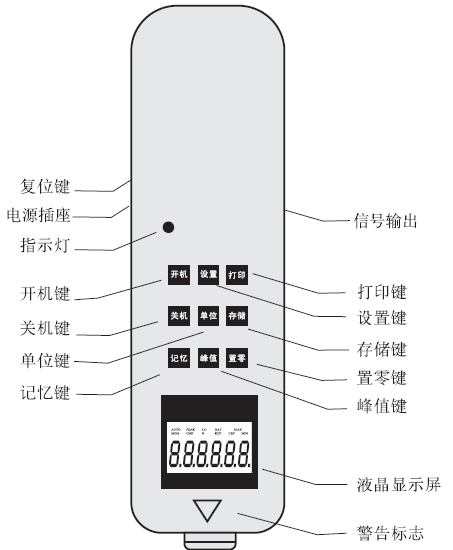

1. Structure name:

1. Structure name diagram

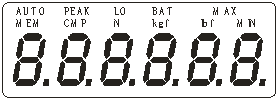

Fourth, the screen display instructions

1. PEAK

When \"PEAK \" is displayed, it indicates Peak mode (peak hold mode), the display shows the peak value until manual zero; when \"AUTO PEAK \" is displayed, it means \"auto peak \" , The peak value is automatically cleared after 3 seconds; when \"PEAK \" is not displayed, it means \"track mode \" (real-time load value mode), and the value on the screen changes with the change of load;

2.LO BAT

When the battery voltage drops below 7.0V, \"LO BAT \" appears on the screen, indicating that the voltage is insufficient and needs to be recharged (it can still be tested while charging);

3. MEM

When data is stored in memory, \"MEM \" will be displayed. Press \"DATA \" to check the memory data, MEM \"flashes;

4. CMP

Compare function.

This function is activated when the comparison value is set by CPDT (see the corresponding explanation later). \"CMP \" is displayed. The comparison value defaults to full scale, and can be set separately according to needs when used.

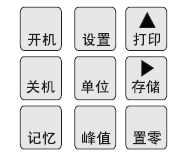

First, the key description (see the figure below)

1. \"Boot \" key

When you press this button, the power is turned on, and the \"power \" indicator will light up (this indicator will also light up when charging), and the model will be displayed. After booting, before pressing the\"zero\" key to clear, the zero drift value of the analog signal may be displayed on the screen, just press the\"zero\" key to clear;

2. \"Shutdown \" key

Whenever this key is pressed, the power is turned off. But the stored memory data will not disappear;

3. \"Memory \" key

When you press this key, the stored test data (memory data) will be recalled and displayed on the screen in sequence, at this time \"MEM \" flashes-first display the number of memories, automatically display the memory data after 2 seconds. Press \"Peak \" key to exit memory;

4. \"Unit \" key

Press this key to switch the measurement unit, and three units of N (Newton), kg (Kilogram), and lb (Pound) can be displayed cyclically. In the test data display state, the unit conversion of the same value can also be completed.

5. \"Peak \" key

Each time you press this key, there will be a switch to display\"PEAK \", display\"AUTO PEAK \", or disappearance of \"PEAK \"-that is, peak hold, peak hold automatic release, and real-time load value switching

6. \"Print \" key

In the test state, press this key to flip the screen 180 degrees.

When \"MODE \" is set, press this key to change the flashing digit between \"0 \" and \"9 \";

7. \"Storage \" key

When you press this key, the test data displayed on the screen will be stored. The stored data can be recalled using the\"\" Memory\"\" key, and can be cleared and cleared using the\"\" Zero\"\" key, and can also be output to the computer for analysis processing or printing using the\"\" Communication \"\" key.

When the test data is stored in the machine, \"MEM \" is displayed;

8. \"Zero \" key

When this key is pressed, the test value on the screen will be reset to zero.

※ When there is a load over 20% of the range of this machine, press \"Zero \" key can not be cleared. At this time, you need to choose a lighter fixture or remove the added load, and clear again;

※ Press and hold this button for 4 seconds, all the stored test data can be cleared (may not be cleared in some states, then restart the machine after shutdown and then execute this function to clear all the memory data).

9. \"Settings \" key

For detailed settings, please refer to the description of various setting methods in \"Function Settings \".

6. MODE function setting:

Press \"Settings \" key in the boot state, at this time there will be set items displayed, the initial display is \"TEST \" ( ), The number setting window appears automatically after 2 seconds. Use \"Print \" key and \"Store \" key to set the test mode; then press \"Settings \" key, \"AODT \" (

), The number setting window appears automatically after 2 seconds. Use \"Print \" key and \"Store \" key to set the test mode; then press \"Settings \" key, \"AODT \" ( ), \"LODT \" (

), \"LODT \" ( ), \"HIDT \" (

), \"HIDT \" ( ), \"CPDT \" (

), \"CPDT \" ( ), The digital setting windows are automatically displayed after the corresponding items appear for 2 seconds, use the \"Print \" key and \"Storage \" key to set the required parameters. \"Setend \" is displayed, indicating that the setting is completed and the test state is entered.

), The digital setting windows are automatically displayed after the corresponding items appear for 2 seconds, use the \"Print \" key and \"Storage \" key to set the required parameters. \"Setend \" is displayed, indicating that the setting is completed and the test state is entered.

0001 Standard test mode

In this mode, three states can be set, namely real-time load state, peak hold state and automatic peak state. When there is no \"PEAK \" on the display, it is the real-time value state of the load, and the test value changes with the change of the load; press \"Peak \" key to display \"PEAK \", the peak hold state

Status, the displayed test value is the maximum value in the test, which needs to be cleared manually; press \"Peak \" key again, \"AUTO PEAK \" display, it is the automatic peak state, the displayed test value is under test The maximum value, and it will automatically disappear and return to zero after being displayed for 3 seconds, and the next test can be performed.

AODT sensor value setting

During the test, set the sensing value Fa. If the value exceeds the induction value, it indicates that the test is started, and then the value is lower than the induction value, indicating that the thrust test is over;

LODT test value lower limit setting

Set the lower limit of the test value, below the lower limit is out of range, \"MIN \" is displayed.

HIDT test value upper limit setting

Set the upper limit of the test value. If the upper limit is exceeded, it is out of range, \"MAX \" is displayed.

CPDT comparison value setting

When the test value exceeds the set comparison value, the buzzer will alarm.

When the user does not know the debugging, (preferably after powering off and restarting), press and hold the \"Settings \" key for more than four seconds, then release the hand after hearing the \"beep \" sound, the instrument can return to the factory default state .

7. Testing

1. Press \"Start \" key to start, press \"Zero \" key, press \"Peak key \" to select measurement mode (real-time load value mode, peak hold mode, peak hold automatic release mode).

2. Loosen the locking hand wheel, the tested elevator rope passes the sensor support point of the load-bearing body, and the two support blocks are in full contact with the rope.

3. After locking the locking hand wheel, the meter will automatically grab the data, which is the tension of the rope.

4. After the test is completed, unload the load, turn off the power, and put all the objects back in the tool box after cleaning to prepare for the next use.

8. Storage (memory) data

1. Store data

Only in the peak hold (PEAK) state, after the test is completed, press \"Save \" key, the data will be stored, the display will show \"MEM \", the stored memory data can also be saved after shutdown . When viewing memory data with the\"\" Memory\"\" key, \"MEM \" flashes, the number of memory appears first, and the memory value automatically appears after 2 seconds. Press \"Peak \" to exit the memory and directly enter the test. Data can also be input into a computer for analysis and processing. This machine can store 896 data. When \"O.E \" is displayed, it means that the 897th data can no longer be stored.

2. Memory clear

When the general load is displayed, press the\"\" Zero\"button for more than four seconds, all the memory data will be cleared, and the word\"\"MEM \" will disappear.

This machine can be connected to a computer and input test data into the computer. View and print the test times, average value, maximum value, minimum value, and determine whether the test results meet the set requirements.

Nine, safety precautions:

Precautions

Incorrect operation may damage the instrument or cause serious accidents. This manual points out important matters for preventing accidents and how to use the instrument. Please read this manual carefully before use, and keep it properly after reading, so that you can read it again.

If you are testing the impact load, please select the model with the maximum load twice the impact load to be tested;

Warning matters

1. During destructive testing, protective masks and gloves should be worn to prevent the splashing material from hurting the human body during the testing process;

2. Do not use the instrument beyond the maximum range. Otherwise, the sensor may be damaged or even an accident may occur;

3. When the test value exceeds 105% of the measuring range, the buzzer will beep continuously. In this case, please quickly release the added load or reduce the load

Safety Precautions

1. Please use the matching charger to charge, otherwise it will cause circuit failure and even fire;

2. Do not use a power supply other than the rated voltage of the charger, otherwise it may cause electric shock or fire;

3. Do not pull out or insert the plug with wet hands, otherwise it may cause electric shock;

4. Do not pull the plug of the charger's power cord to pull out the plug, so as to avoid the electric cord being broken and being subjected to electric shock;

5. Please clean the machine with a soft cloth. Immerse the cloth in water soaked with detergent, wring it out and remove dust and dirt;

Note: Do not use volatile chemicals to clean the machine (such as volatile agent, thinner, alcohol, etc.)

6. Do not operate the machine in the following environment

(1) Humid environment;

(2) Dusty environment;

(3) Where oil or chemicals are used;

(4) Places with earthquake sources around.

7. Please use and store within the specified temperature and humidity range, otherwise it may cause instrument failure;

8. Do not disassemble, repair or modify the machine by yourself, these actions may cause permanent failure of the instrument;

9. Other matters that need to be paid attention to in safety production.

10. List of random attachments

|

Serial number |

name |

Quantity |

|

1 |

Host |

1 |

|

2 |

Sensor bearing body |

1 |

|

3 |

CD |

1 |

|

4 |

Data cable |

1 |

|

5 |

Power Adapter |

1 |

|

6 |

Inspection certificate |

1 |

|

7 |

user's Guide |

1 |

|

8 |

Certificate of conformity |

1 |