1.1 Main uses and scope of application

ANBH torque wrench tester is a special equipment for testing torque wrenches and torque drivers. Mainly used for testing or calibrating torque wrenches, preset torque wrenches, pointer torque wrenches. Widely used in electrical manufacturing, mechanical manufacturing, automotive light industry, professional scientific research and testing industries. The torque value is displayed through a digital meter, which is accurate and intuitive.

1.2 Product features

This instrument is a digital torque wrench tester specially designed for calibrating or adjusting torque wrenches.

(1) Multiple units can be selected

Units of measurement include Newton units (N.m), metric units (kgf.cm) and US units (lbf.in).

(2) Two measurement modes

The real-time and peak modes of this instrument can be switched at will.

(3) Upper and lower limit settings

The upper and lower limits of this instrument can be set. When the set value is reached, the buzzer will alarm.

(4) Data saving function

This instrument can save 100 sets of measurement data.

1.3 Variety specifications

Second, the overall product structure

|

specification |

ANBH-20 |

ANBH-50 |

ANBH-100 |

ANBH-200 |

ANBH-500 |

||

|

Maximum |

20N.m |

50N.m |

100N.m |

200N.m |

500N.m |

||

|

Minimum resolution |

0.001 |

0.001 |

0.001 |

0.01 |

0.01 |

||

|

Accuracy |

± 1% |

||||||

|

Unit switch |

N.m, Kgf.cm, Lbf.in |

||||||

|

power supply |

Input: AC 220v Output: DC 12V |

||||||

|

Dimensions mm |

299 * 299 * 242 |

772 * 400 * 276 |

1142 * 553 * 360 |

||||

|

Operating temperature |

5 ℃ ~ 35 ℃ |

||||||

|

Transport temperature |

-10 ℃ ~ 60 ℃ |

||||||

|

Relative humidity |

15% ~ 80% RH |

||||||

|

working environment |

No vibrating sources and corrosive media around |

||||||

|

Weight (Kg) |

12 |

27 |

43 |

||||

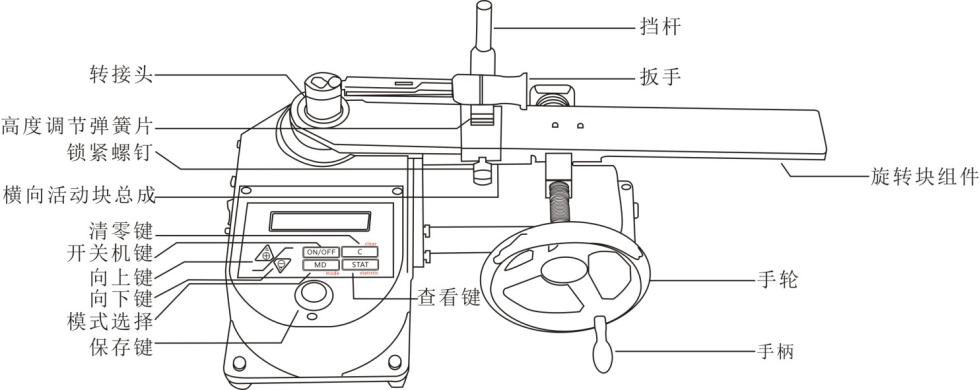

2.1 Overall structure

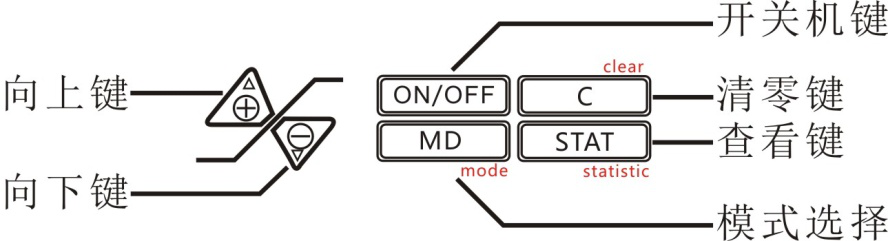

2.2 Key introduction

2.2.1 Up key: Press this key on the measurement interface to rotate the measured data by 180 °.

2.2.2 Down key: In the setting interface, it has the function of down selection and displacement.

2.2.3 Switch key: power on and off function.

2.2.4 Clear key: The measurement interface has data clear function, and the setting interface has return function.

2.2.5 View key: In the measurement interface, there is a function to view saved data.

2.2.6 Mode selection: In the measurement interface, press this key to switch between peak mode and real-time measurement mode. Long press this key for 6 seconds to enter the setting interface. This key has a save function in the setting interface.

3. Function introduction

3.1 Setting items:

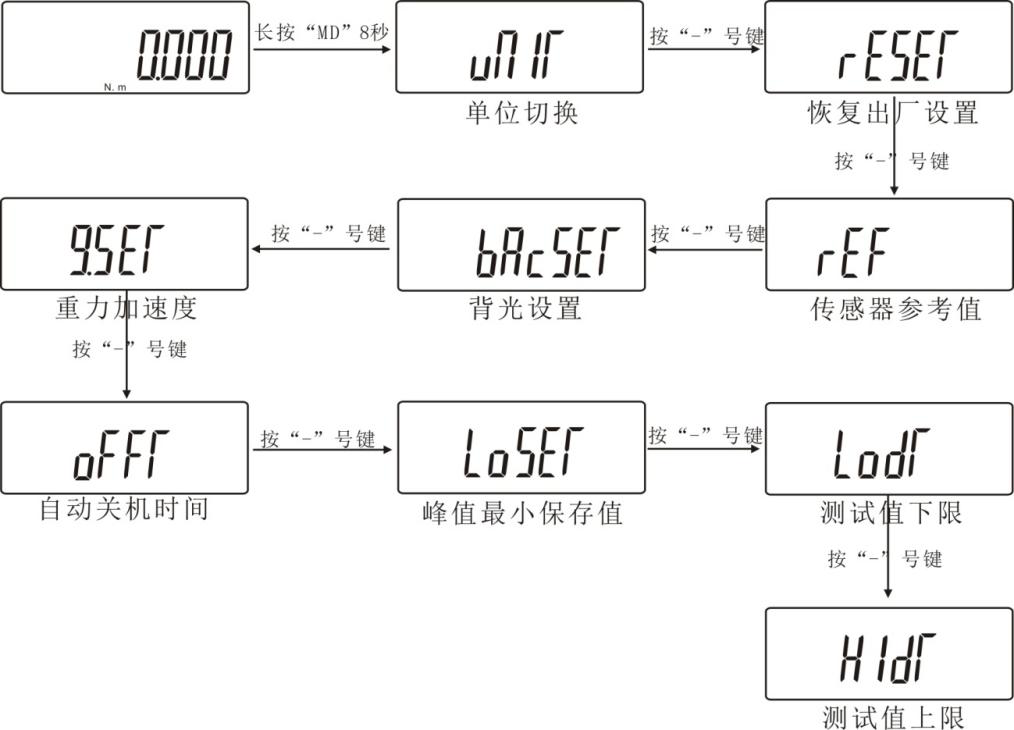

3.1.1 In the measurement interface, press and hold \"MD \" for 8 seconds to enter the setting interface, as shown in the following figure:

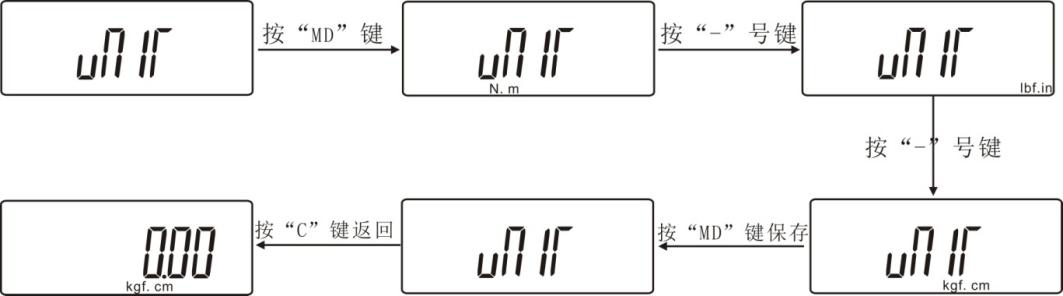

(UNIT) Unit setting: The instrument can switch 3 units. After entering the unit setting interface, press \"+ \" or \"-\" to select the unit, as shown in the following figure:

(UNIT) Unit setting: The instrument can switch 3 units. After entering the unit setting interface, press \"+ \" or \"-\" to select the unit, as shown in the following figure:

(RESET) Restore factory settings function: Under this setting item, press \"MD \" key to restore the factory settings, and the machine will shut down. If you use the machine to restart the machine.

(RESET) Restore factory settings function: Under this setting item, press \"MD \" key to restore the factory settings, and the machine will shut down. If you use the machine to restart the machine.

(REF) Factory setting value: It has nothing to do with users.

(REF) Factory setting value: It has nothing to do with users.

(BACSET) Backlight function setting: Under this setting item, use \"+ \" or \"-\" key to select, select \"

(BACSET) Backlight function setting: Under this setting item, use \"+ \" or \"-\" key to select, select \" (YES) \"Backlight on, choose \"

(YES) \"Backlight on, choose \" (NO) \"Backlight off, press \" MD \"key to save after selection, return to the setting interface.

(NO) \"Backlight off, press \" MD \"key to save after selection, return to the setting interface.

(G.SET) Gravity acceleration setting: The user can set the gravity acceleration value according to the location of the region, the default value is 09.800.

(G.SET) Gravity acceleration setting: The user can set the gravity acceleration value according to the location of the region, the default value is 09.800.

(OFFT) Automatic shutdown time setting: Under this setting item, use \"+ \" and \"-\" to select, you can set the automatic shutdown from 0 minutes to 9999 minutes, or you can set \"0000 \" Automatic shut-down. If you do not want to shut down automatically, press \"MD \" to complete the setting after selection and return to the setting interface. The default setting of the instrument is 10 minutes.

(OFFT) Automatic shutdown time setting: Under this setting item, use \"+ \" and \"-\" to select, you can set the automatic shutdown from 0 minutes to 9999 minutes, or you can set \"0000 \" Automatic shut-down. If you do not want to shut down automatically, press \"MD \" to complete the setting after selection and return to the setting interface. The default setting of the instrument is 10 minutes.

(LOSET) Peak minimum saved value: minimum peak saved value. In peak mode, when the current value is less than this value, the peak value will not be saved.

(LOSET) Peak minimum saved value: minimum peak saved value. In peak mode, when the current value is less than this value, the peak value will not be saved.

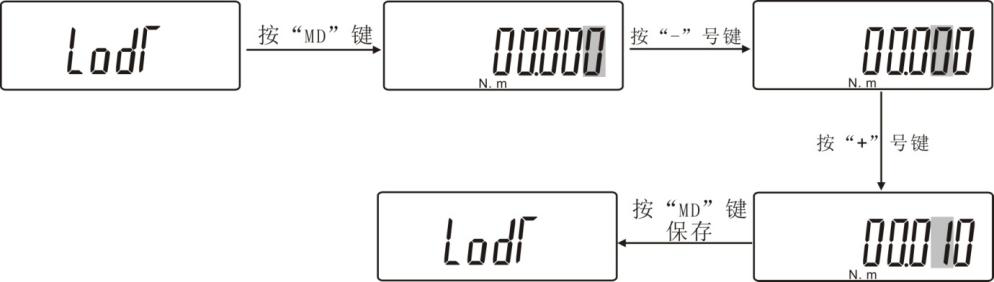

(LODT) Test value lower limit setting: Set the test value lower limit, the default value is 0 by default. Below the lower limit is out of range, \"MIN \" is displayed. The lower limit of this instrument is 0 by default. If you want to reset the lower limit, under this setting item, use \"+ \" and \"-\" keys to set. Press \"MD \" to save and return to the setting interface. As shown below:

(LODT) Test value lower limit setting: Set the test value lower limit, the default value is 0 by default. Below the lower limit is out of range, \"MIN \" is displayed. The lower limit of this instrument is 0 by default. If you want to reset the lower limit, under this setting item, use \"+ \" and \"-\" keys to set. Press \"MD \" to save and return to the setting interface. As shown below:

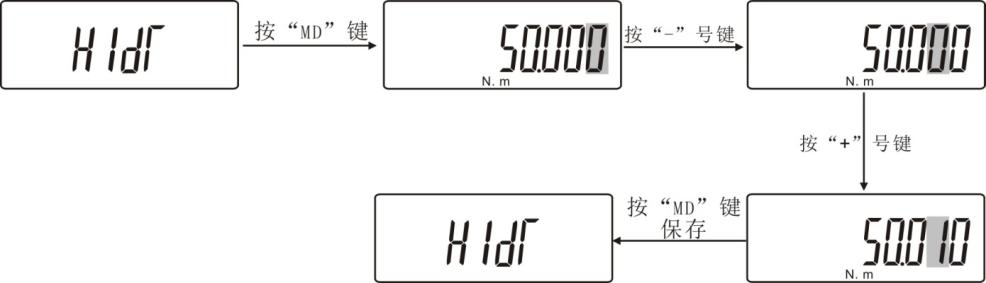

(HIDT) Test value upper limit setting: Set the test value upper limit, and the upper limit value defaults to full scale. Above the upper limit is out of range, \"MAX display \". The default upper limit value of this instrument is full scale. If you want to reset the upper limit, under this setting item, you can use \"+ \" and \"-\" keys to set. Press \"MD \" to save and return to the setting interface.

(HIDT) Test value upper limit setting: Set the test value upper limit, and the upper limit value defaults to full scale. Above the upper limit is out of range, \"MAX display \". The default upper limit value of this instrument is full scale. If you want to reset the upper limit, under this setting item, you can use \"+ \" and \"-\" keys to set. Press \"MD \" to save and return to the setting interface.

3.2 View saved data

After saving the measurement data, press \"STAT \" key, \"1 \" appears on the screen, indicating the first set of stored data, then the screen automatically displays the saved data, then press \"+ \", \"2 \", The screen automatically displays the saved second set of data, press \" + \", \" 3 \"appears, the screen automatically displays the saved third set of data, and then press \" STAT \"screen display \" 3 \" , Indicating the total number of groups of stored data, and then pressing \"STAT \" key will display the maximum value of the stored data sum, then press \"STAT \", it will display the minimum value of the stored value sum, then press\"STAT \", The average value of the sum of the stored values will be displayed, and then you can press \" C \"to return to the measurement interface. As shown below:

Fourth, the calibration method

4.1 Calibration conditions

4.1.1 Before starting the torque wrench calibration, please check the following.

(1) Place the torque wrench tester on a stable workbench.

(2) For direct-reading torque wrenches, when reading the measurement data, the line of sight must be perpendicular to the dial.

(3) For the trip-type torque wrench, apply the maximum torque of each model 5 times in both directions for trial operation to perform the preheating operation.

(4) For direct-reading torque wrenches, load the maximum torque of each model once in both directions as a warm-up operation, and ensure that the pointer or digital display shows \"0 \" after loading.

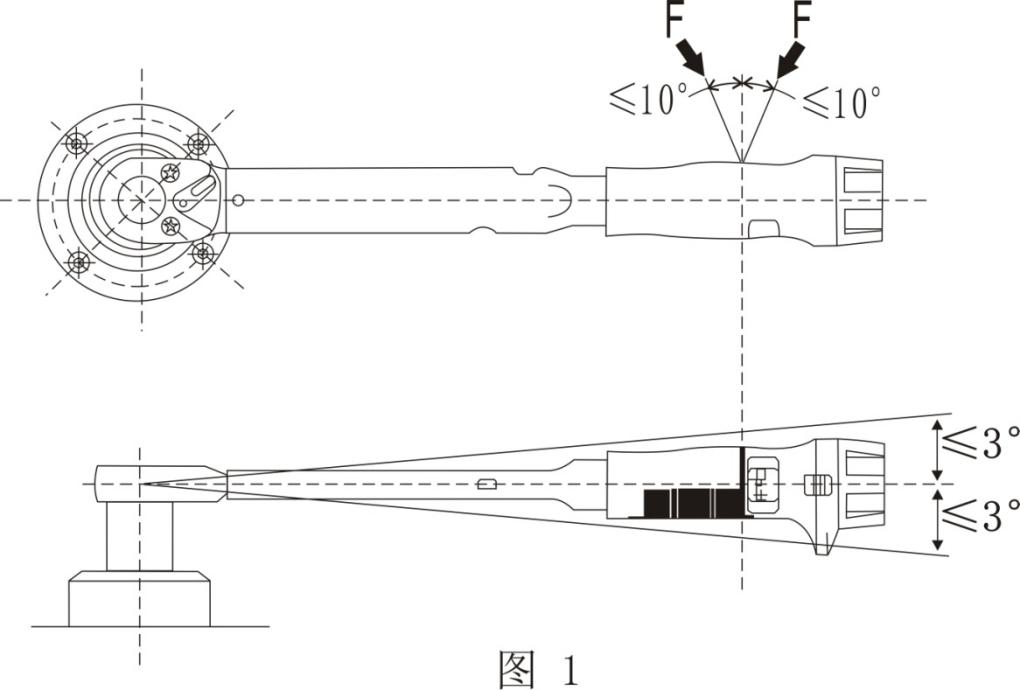

(5) Apply the load within the range specified in Figure 1 at the center of the handle or at the marked load point.

4.2 Notes on calibrating torque wrench

(1) For the tripping torque wrench, load the initial torque to 80% of the target torque, and then slowly and evenly apply the remaining torque. (The last 20% takes 1-3 seconds.) The preset torque wrench must start at a low level and then adjust to the target torque. (Do not drop from a high level to the target torque.)

(2) For direct-reading torque wrenches, gradually apply torque to the target torque, being careful not to exceed the target torque. If you accidentally exceed the target torque, loosen the torque to zero and restart the process.

5. Operation steps

5.1 When using the instrument for the first time, the horizontal slide block and handle must be installed.

5.2 Slide the horizontal movable block assembly into the rotating block assembly and fix it in a certain position with locking screws.

5.3 Rotate the handle into the handwheel.

5.4 Plug in the power cable.

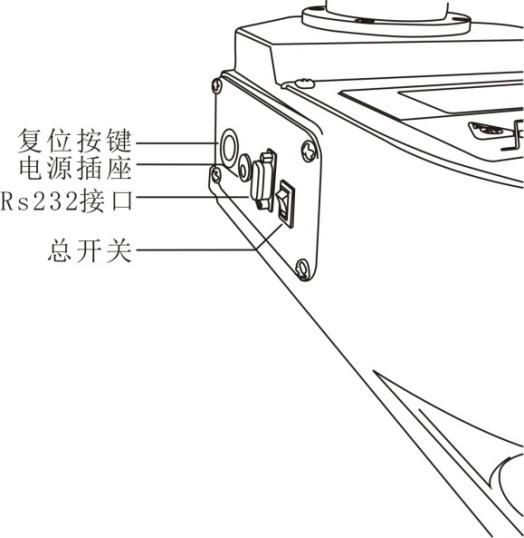

5.5 Turn on the main switch and press the power button.

5.6 Put the torque wrench into the adapter.

5.7 Adjust the height adjustment spring and the length adjustment nut to the appropriate position, and then clear the display.

5.8 Select the desired unit and measurement mode

5.9 Shake the handwheel to start testing until the instrument emits a \"click\" to complete the testing.

Six, matters needing attention, maintenance and repair

6.1 Do not overload the torque test, be sure to test within the allowable range of the instrument, otherwise it will damage the instrument.

6.2 Do not hit or scratch the display with sharp objects such as heavy objects and sharp objects.

6.3 Do not use the torque wrench calibrator where water, oil or other liquids are splashed. Store the torque wrench calibrator in a cool, dry and vibration-free place.

6.4 Please use the matching power adapter to charge, otherwise it will cause circuit failure and even fire.

6.5 Insert the AC power adapter completely into the socket before using it. Loose plugs may cause a short circuit, resulting in electric shock or fire.

6.6 Please do not pull out or insert the plug with wet hands, otherwise it may cause electric shock.

6.7 Please clean the machine with a soft cloth, immerse the dry cloth in the water soaked with detergent, wring it out to remove dust and dirt. Do not use chemicals that emit easily, such as volatile agents, thinners, alcohol, etc.

6.8 Handle gently during use and handling.

6.9 Do not disassemble, repair or modify the machine by yourself. These actions may cause permanent failure of the instrument.

6.10 Please contact the original place of purchase or our company if a fault occurs.

Seven, packing list

|

1 |

Torque wrench tester |

1 set |

|

2 |

Instructions |

1 serving |

|

3 |

Adapter |

See packing list |

|

4 |

Power adapter 12V |

1 |

|

5 |

Certificate of conformity and warranty card |

1 serving |

|

6 |

Inspection certificate |

1 serving |

|

7 |

Desiccant |

1 package |