1. Purpose

The torque wrench tester is a special equipment for testing torque wrenches and torque screwdrivers. It is mainly used for testing various constant-force torque wrenches, digital display torque wrenches and preset torque wrenches. Widely used in electrical manufacturing, mechanical manufacturing, automotive light industry and professional scientific research and testing industries. Digital and instrument display of torque value, accurate and intuitive, simple preparation of various mortises, easy to clamp.

2. Features

1. High precision, high resolution and fast sampling speed.

2. Instrument display, curve display, curve zoom function, full touch screen display.

3. Adopt high-precision torque sensor with torque direction display.

4. The upper and lower limits can be set, red font prompt and buzzer alarm.

5. The three units can be converted to each other for selection (N · m, kgf · cm, lbf · in).

6. Real-time and peak two modes can be switched at will.

7. The system time can be set.

8. Store a large amount of data in the form of U disk.

3. Specifications

|

model index |

100 |

200 |

300 |

500 |

1000 |

2000 |

3000 |

|

|

measuring range / Minute Degree |

N · m |

100.0 / 0.01 |

200.00 / 0.01 |

300.00 / 0.01 |

500.00 / 0.01 |

1000.0 / 0.1 |

2000/0.1 |

3000/0.1 |

|

Kg · cm |

1021.0 / 0.1 |

2042.0 / 0.1 |

3063.1 / 0.1 |

5105.2 / 0.1 |

10210/1 |

20420/1 |

30631/1 |

|

|

Ib · in |

886.2 / 0.1 |

1772.4 / 0.1 |

2658.6 / 0.1 |

4431.1 / 0.1 |

8862/1 |

17724/1 |

26586/1 |

|

|

Dimensions |

880mm × 350mm × 550mm |

1250mm × 500mm × 800mm |

||||||

|

Checked length range |

130mm ~ 750mm |

250mm ~ 980mm |

250mm ~ 1800mm |

|||||

|

Rotation angle |

0 ~ 60 ° |

0 ~ 360 ° |

||||||

|

Height travel |

130mm |

150mm |

||||||

|

Accuracy |

± 1% |

|||||||

|

Peak sampling frequency |

2000HZ |

|||||||

|

power supply |

AC220V / 50Hz |

|||||||

|

Net Weight |

65Kg |

335kg |

||||||

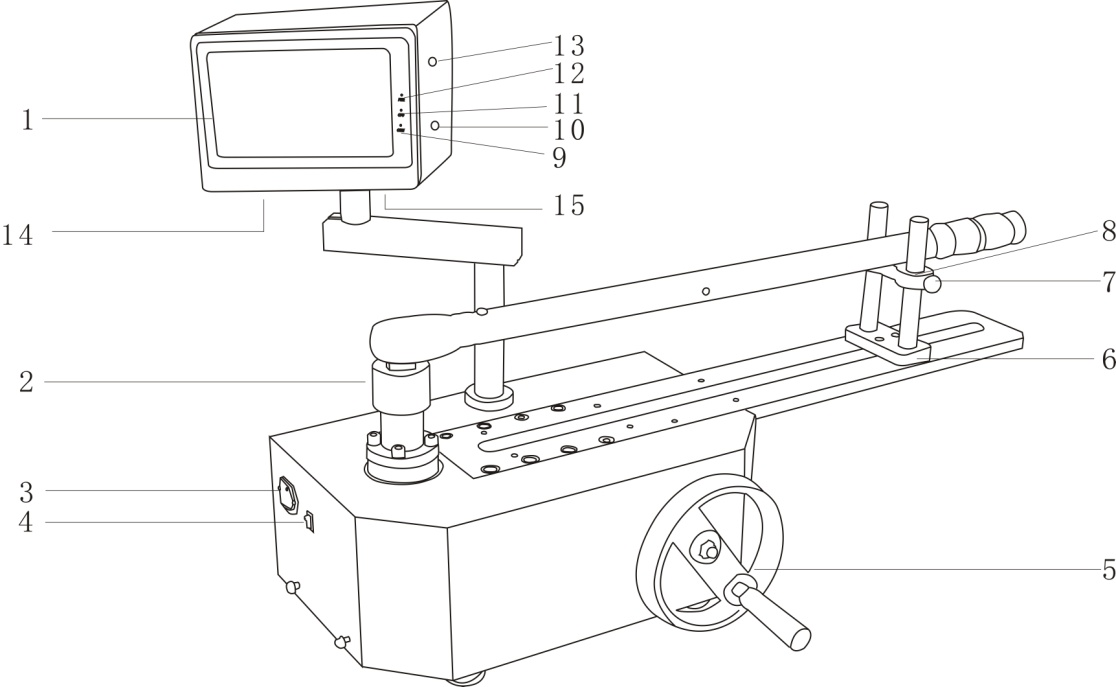

Fourth, the name and function of each part

1. LCD touch screen 8. Height adjustment block

2. Mortise 9. Window indicator

3. Power interface 10. Clear button

4. Hard switch 11. CPU indicator

5. Handwheel 12. Power indicator

6. Length adjustment block 13. LCD screen switch

7. Height adjusting nut 14. Network cable port

15. USB jack

1. LCD touch screen

a. Start the measurement interface

2. Function buttons

a, \"LANGUAGE \" key: language switch key, press to switch between Chinese and English.

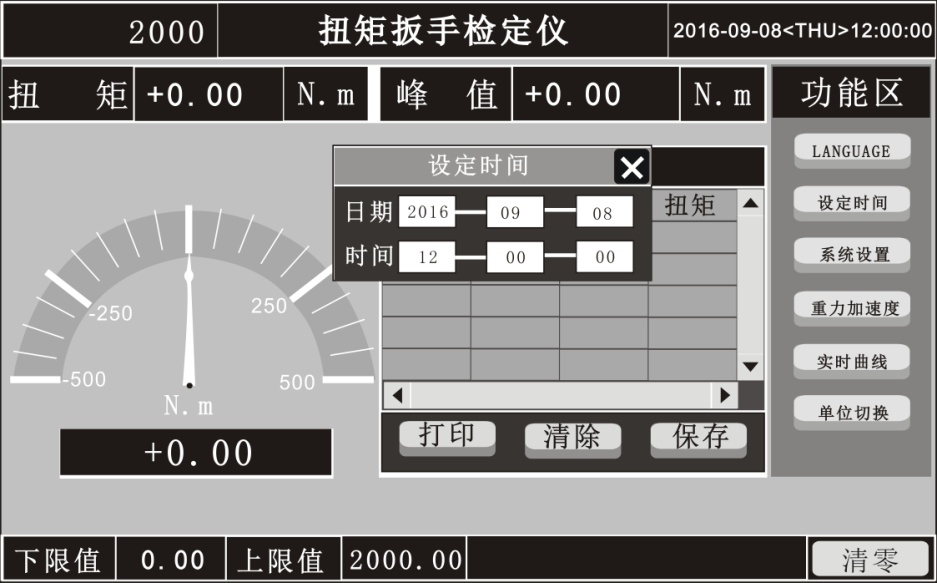

b. \"Set Time \" key: Time setting key, press it, a \"Set Time \" dialog box will appear, you can freely modify the date and time, as shown in the following figure:

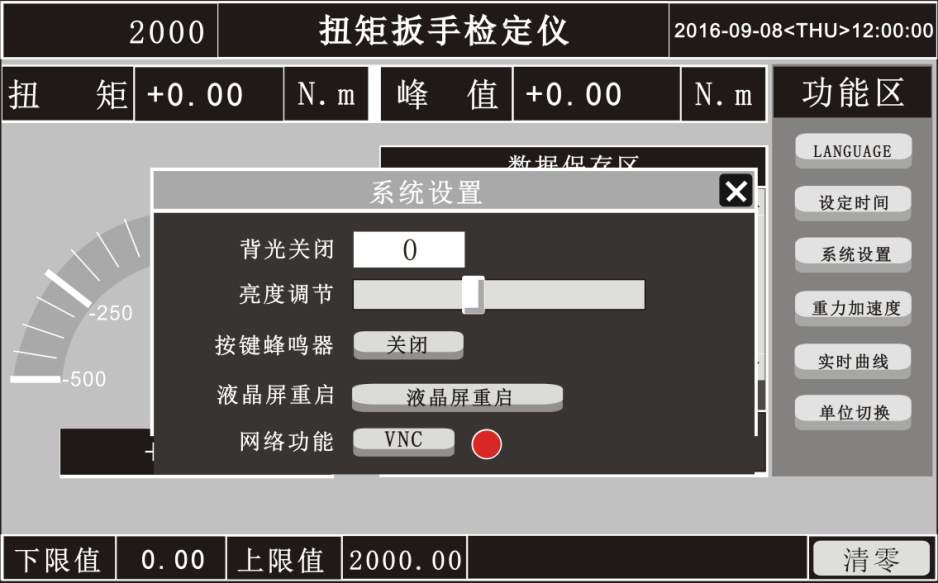

c. \"System Settings \" key: including \"Backlight \", \"Screen Brightness \", \"Key Buzzer \", \"LCD Screen Restart \", \"Network Function \" 5 functions .

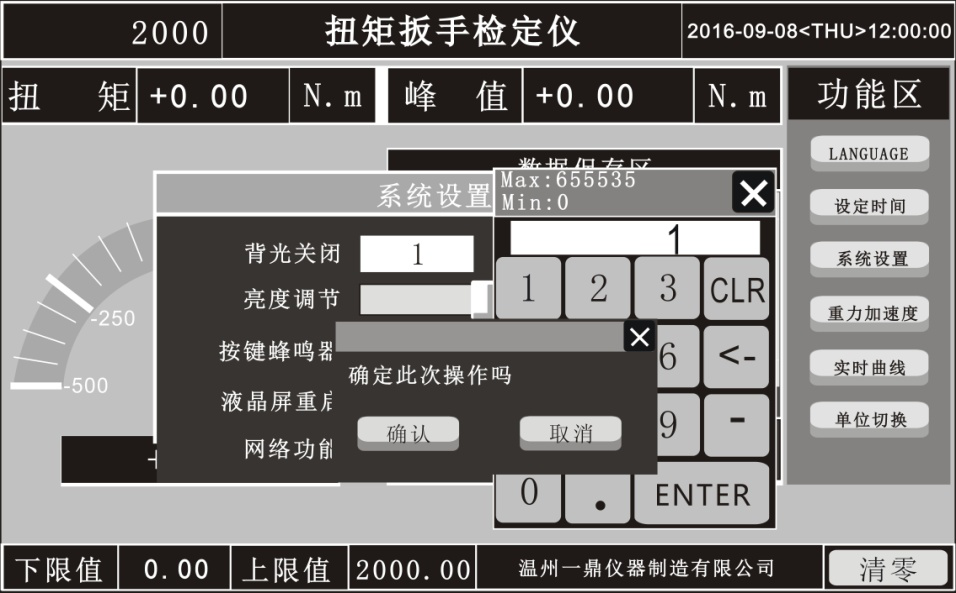

As shown below:

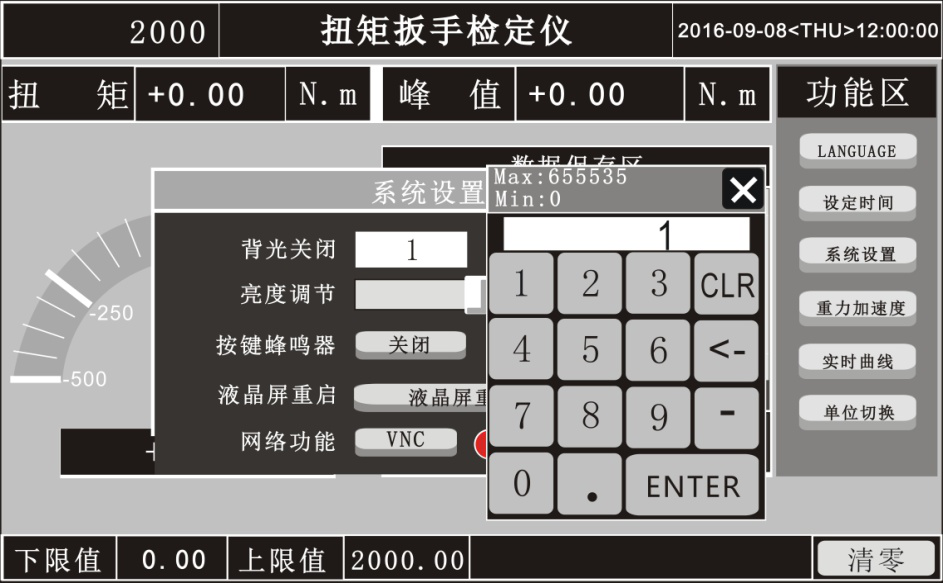

\"Backlight off \" setting: Click \"Backlight off \" box, the box shown below will appear:

You can freely input the number you want to set, for example: \"1 \" (here the time unit is: minutes), the dialog box has: \"Max: 655535, Min: 0 \", indicating that the input number is up to \"655535 \", the minimum is \"0 \", then press \"ENTER \", a new dialog box will appear, press OK to set. As shown below:

\"Key Buzzer \": After pressing \"Close \", the key sound will be cancelled.

\"LCD screen restart \": After pressing \"LCD screen restart \", the screen will restart.

\"Network function \": After clicking \"VNC \", the red on the right turns to green light, the network function is turned on, after plugging in the network cable, it can be connected to the upper computer on the computer, and the torque wrench tester can be operated on the computer .

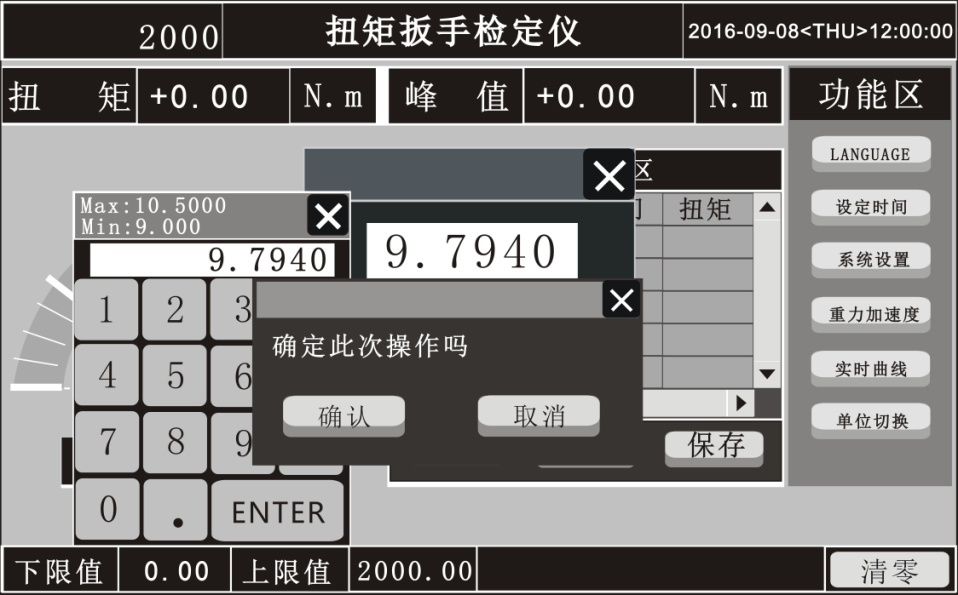

d. \"Gravity acceleration \" key: Set \"Gravity acceleration \", press to display a dialog box, as shown below:

The default gravity acceleration is \"9.7940 \", click the white box when you want to modify, a new dialog box will appear, as shown below:

Enter the value to be set (Max: 10.5000, Min: 9.000 at the top of the dialog means that the maximum value can be set to 10.5000 and the minimum value can be set to 9.000), press \"ENTER \", a new dialog box will appear, press \ OK \". As shown below:

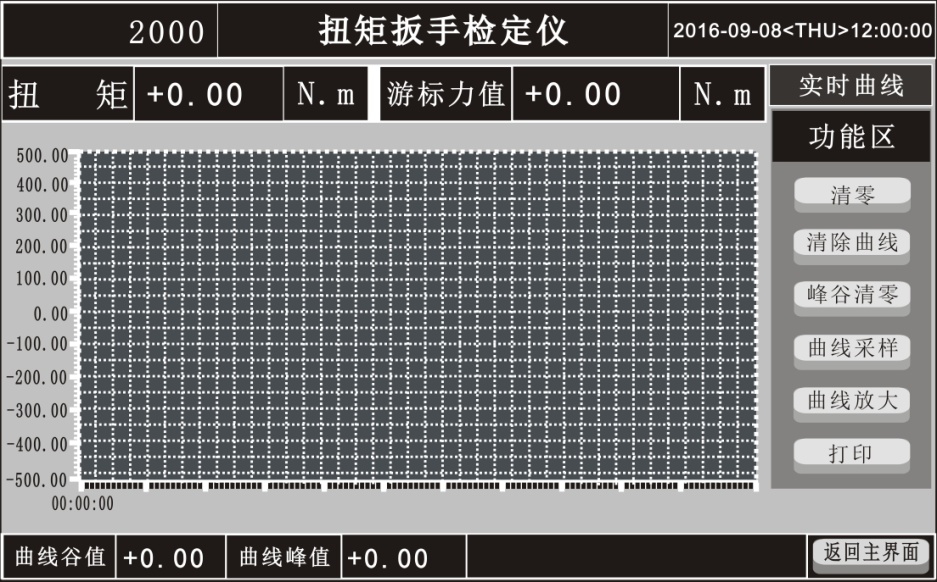

e, \"Real-time curve \": display the real-time test force value in a curve mode. Press \"Real-time curve \", it will enter \"Real-time curve \" interface, as shown below:

\"Cursor force value \": It is the force value at any point on the curve, (click the curve to point, \"cursor force value \" will display the value).

\"Clear \": Press \"Clear\" to clear the peak value of the curve.

\"Clear Curve \": Clear the curve on the screen. (The curve will not be cleared by pressing this key after pressing \"curve magnification \". You need to double-click the screen to restore the curve to the normal size, and then press this key to clear the curve).

\"Peak valley clear \": Clear the value of \"curve valley \" or \"curve peak \" displayed at the bottom of the screen (the value of \"curve peak \" is cleared when measuring peak value, and cleared when measuring valley value \"Curve Valley Value\".

\"Curve Sampling \": Let the force value be displayed in the form of a curve, click to start the curve force value display, and then click to pause.

\"Curve Zoom \": After pressing this key, dragging the screen curve will zoom in.

\"Return to main interface \": Click this button to return to the main interface.

f. Unit switching: The three units are switched between each other. One button switches one unit. There are three units in this instrument (N · m, kgf · cm, Ib · in).

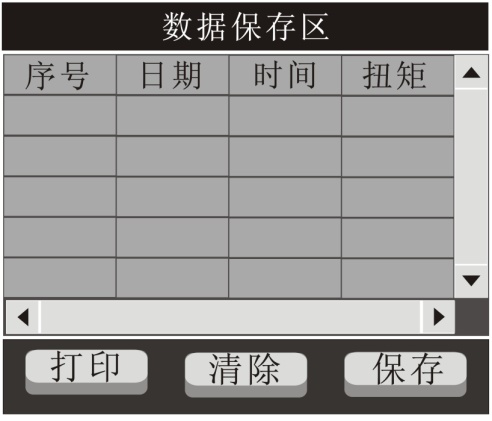

3. Data storage area

\"Save \" key: save the data.

\"Clear \" key: Clear the data.

4. Power interface: connect the power supply to use the instrument (this instrument has no charging function).

5. The square hole of bearing: connect with the square probe of the tested object.

6. Test object: such as torque wrench, torque wrench, etc.

7. Handwheel: Rotate the handwheel to detect.

8. USB jack: After the instrument is running, insert the U disk into the USB hole, and the data when the instrument is running will be automatically saved to the U disk in the form of Excel.

5. Working environment

1. Operating temperature: -10 ℃ ~ 40 ℃.

2. Operating humidity: ≤90% RH.

3. There is no vibration source and no corrosive environment around.

6. Operation steps

1. Plug in the power cable and put it into the square hole.

2. Turn on the hard switch.

3. Place the test object, and place the test probe of the test object into the load-bearing square hole of the tester.

4. The tail of the test object does not touch foreign objects, adjust the height adjustment block and length adjustment block, and the display screen is cleared.

5. Shake the handwheel to start detection.

6. If you want to change the unit during testing, press \"Unit Switch \", the three units switch between each other, and you can switch one unit by clicking. There are three units in this instrument (N · m, kgf · cm, Ib · in ).

7. If you want to see the curve display of the force value during detection, press \"Real-time curve \" key to enter \"Real-time curve \" interface, then press \"Curve sampling \", then shake the handwheel, the curve will appear When you want to pause, press \"curve sampling \" again, it will pause.

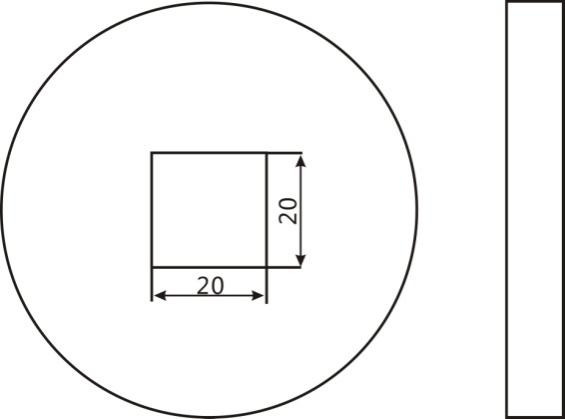

Seven, bearing square hole size

It is not allowed to hit the bearing square holes at will to avoid damage. The following is a plan view of a square hole bearing:

8. Matters needing attention, maintenance and repair

1. Do not overload the torque test, be sure to test the torque within the test range of the torque tester, otherwise the instrument will be damaged and more likely to be dangerous.

2. Do not strike or scratch the display screen with sharp objects such as heavy objects and sharp objects.

3. Do not use the torque tester where water, oil or other liquids are splashed. Store the torque tester in a cool, dry and vibration-free place.

4. Please do not open the cover behind the display, let alone adjust the trimming resistor inside.

5. Do not loosen the fixing screws of the torque test head.

6. Please use the matching power adapter to charge, otherwise it will cause circuit failure and even fire.

7. Insert the AC power adapter completely into the socket before use. Loose plug may cause a short circuit and cause electric shock or fire.

8. Do not use any power source other than the rated voltage of the power adapter, otherwise it may cause electric shock or fire.

9. Please do not pull out or insert the plug with wet hands, otherwise it may cause electric shock.

10. Please clean the machine with a soft cloth, immerse the dry cloth in the water soaked with detergent, wring it out and remove the dust and dirt. Do not use chemicals that emit easily, such as volatile agents, thinners, alcohol, etc.

11. Handle gently during use and handling.

12. Do not disassemble, repair or modify the machine by yourself. These actions may cause permanent failure of the instrument.

13. Please contact the original place of purchase or our company if a fault occurs.

14. Within one month from the date of sale, the product has quality problems under normal use and no damage to the appearance. The customer shall return the original specification of the sales invoice, valid warranty card and complete packaging to the original place of purchase or replace the same specifications For the model product, the replacement product will continue the warranty period and terms of the original product.

15. Within one year from the date of sale, under normal use, non-human faults are covered by the warranty (users dismantle the machine or repair the company's products at other repair points without warranty). Contact the original place of purchase with a valid warranty card to get a one-year free warranty from our company.

16. The terms of this product only apply to digital torque tester products sold in the Chinese market. For products that exceed the replacement period and warranty period, customers can check the original purchase place for maintenance or contact the company, provided by the company Paid maintenance.

Other supporting instruments

|

equipment name |

model |

equipment name |

model |

|

Digital push-pull force gauge |

HF |

Electric vertical machine |

AEV |

|

Pointer push-pull force gauge |

NK |

Electric single column vertical machine |

AEL |

|

Digital torque tester |

ANL |

Electric horizontal machine |

AEH |

|

Bottle Cap Torque Tester |

ANL—P |

Spiral side roll test machine |

ASC |

|

Pointer torque screwdriver |

ANQ |

Manual horizontal test stand |

AMH |

|

High-speed impact torque tester |

AGN |

Manual vertical and horizontal test stand |

ASL |

|

Dynamic torque tester |

AND |

Hand-pressed tensile and compression test stand |

AST |

|

Torque wrench tester |

ANJ |

Spiral tension and compression test stand |

ALX |

|

Torsion spring testing machine |

ANH |

Special testing machine for peeling force |

ABL |

|

Spring tension and compression testing machine |

ATH |

Ball pressure test device |

AQY |

|

Shore Rubber Hardness Tester |

LX |

Motorized hydraulic tension and compression test stand |

ALR |

|

Shore Hardness Test Stand |

LAC—J |

Button Tester |

ABQ |

|

Fruit Hardness Tester |

AGY |

Terminal tensile tester |

ADL |

|

Fruit Hardness Tester Stand |

GYJ |

Rope tension meter |

ASZ |

|

Tonometer |

ATN |

Side pressure tension tester |

HD |