AWEC Interchangeable head With angleTorque wrenchuse Explanation书

1,System Overview

1.1 Main uses and scope of application

AWECThe interchangeable headband angle digital display torque wrench is a new type of digital display wrench.Its own ratchet head can be replaced with plugs such as open head, plum head, movable open head, etc. It has powerful operation functions, including torque setting; unit setting; mode setting; value storage; value clearing; value output and user correction Features,The torque-angle value can be read directly and accurately, which is simple to use and easy to operate. It is suitable for bolt tightening and control in automobile industry and machinery industry.

1.2 Features

1.2.1 The torque-angle value can be read directly;

1.2.2 ± 1 ° (rotate 90 ° at 30 ° / sec);

1.2.3Clockwise ± 2%, counterclockwise ± 2.5% accuracy (20 ~ 100% of the maximum operating range)

1.2.4 Can measure clockwise and counterclockwise;

1.2.5 The buzzer, LED and vibrator prompt the target value;

1.2.6 Four torque units: N.m, kfg.cm, ft.lbf, in.lbf, etc.

1.2.7 The angle unit is degree (°)

1.2.8 Comes with 3.7V lithium battery, which can directly charge the lithium battery through USB;

1.2.9 comes with usb interface, you can upload and save data.

1.2.10 Measurement mode: Real-time mode, peak mode and preset mode are three measurement modes.

1.2.11 Automatic backlight function;

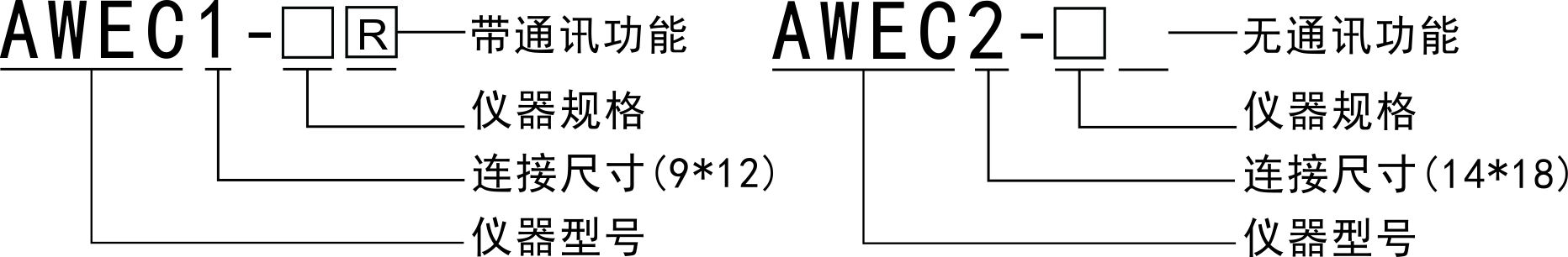

1.3 Product model selection

1.4Specifications

|

model |

Unified beltcommunication |

010R |

030AR |

030BR |

060R |

085R |

135R |

135R |

200R |

340R |

||

|

Minimum division value |

0.01 0.1 |

0.1 |

||||||||||

|

Maximum operating range (N.m) |

10N.m / 7.37ft.lb / 88.50in.lb / 101.97kgf. cm |

30N.m / 22.12ft.lb / 265.5in.lb / 305.91kgf.cm |

30N.m / 22.12ft.lb / 265.5in.lb / 305.91kgf.cm |

60N.m / 44.25ft.lb / 531.04in.lb / 611.82kgf. cm |

85N.m / 62.69ft.lb / 752.31in.lb / 866.75kgf. cm |

135N.m / 99.57ft.lb / 1195in.lb / 1376.61kgf. cm |

135N.m / 99.57ft.lb / 1195in.lb / 1376.61kgf. cm |

200N.m / 147.5ft.lb / 1770in.lb / 2039.43kgf. cm |

340N.m / 250ft.lb / 3009in.lb / 3467.03kgf. cm |

|||

|

Connector (inches) |

9 * 12 |

14 * 18 |

||||||||||

|

length |

390 |

420 |

535 |

655 |

||||||||

|

Torque accuracy * 1 |

±2%, 2.5% |

|||||||||||

|

Angle accuracy |

± 1 ° (the accuracy of the angle measured at a speed of 30 ° per second to 90 °) |

|||||||||||

|

Data storage capacity |

255 |

|||||||||||

|

Operating mode |

Peak mode (P) / real-time mode (T) / preset mode (Pre) |

|||||||||||

|

unit |

N.m, kgf.cm, ft.lbf, in.lbf |

|||||||||||

|

Ratchet head form |

Pre-installed ratchet head can be replaced with plugs such as open head, plum head, movable open head, etc. |

|||||||||||

|

Number of keys |

5 |

|||||||||||

|

battery |

3.7V lithium battery |

|||||||||||

|

Operating temperature |

-10 ℃ ~ 60 ℃ |

|||||||||||

|

storage temperature |

-20 ℃ ~ 70 ℃ |

|||||||||||

|

humidity |

90% without condensation |

|||||||||||

|

Drop test height |

1 meter |

|||||||||||

|

Vibration test conditions * 2 |

10G |

|||||||||||

|

Life test * 3 |

10000 times |

|||||||||||

Note: (030A / B can choose two ratchet head configurations, A- means 1/4, B- means 3/8, the factory default is 1/4 configuration)

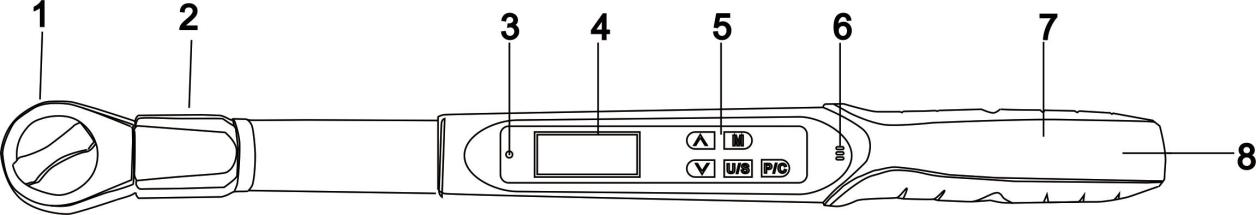

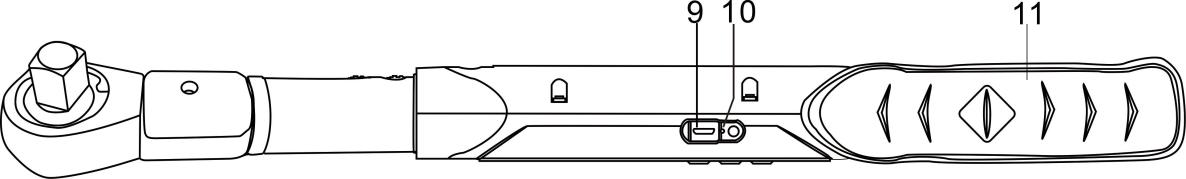

2. Product components

2.1 Product structure

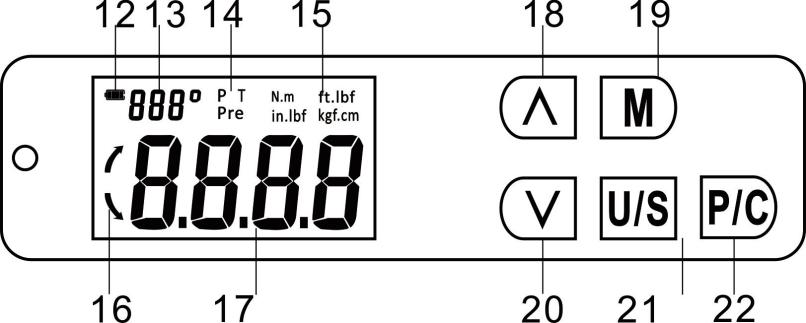

2.2 LCD display

1,Pre-installed ratchet head(Interchangeable)2,sensor

3. LED indicator4. LCD screen

%1,button6. Buzzer

7.Battery case 8. Battery cover

9, USB / charging interface 10,charging indicator

11, Grip 12、 Battery power display

13, Angle value display 14,Operating mode

15, Unit display 16, Torque direction

17, Torque value display 18, Up / preset value unlock button

19, Storage / view button20, Down / working mode switch button

21, Unit switch / Menu button 22, Power / zero button

3. Description of working mode

3.1 Working mode switch

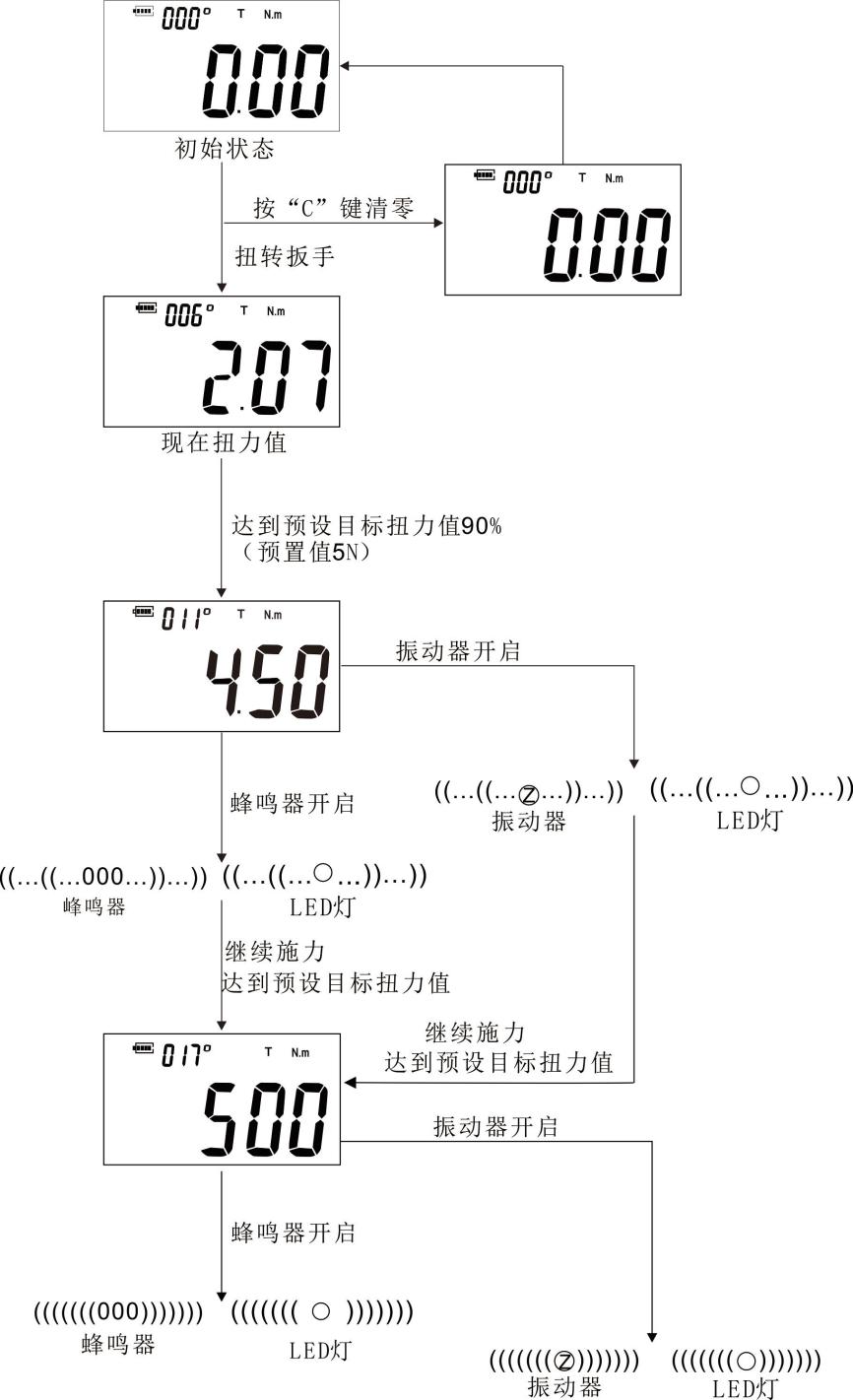

3.2 Real-time mode operation

The real-time measurement mode follows the applied torque value and the rotation angle value (when the rotation angle value is greater than 0, the selected angle is calculated) When unloading torque,Torque value to zero, The angle is automatically cleared.

When the LCD shows T,forIn real-time mode, if T is not displayed, press \" \"Key to switch the mode. The operation steps are shown in the following figure:

\"Key to switch the mode. The operation steps are shown in the following figure:

NOTE1: In real-time mode, when the torque value is greater than 0, the angle value will be displayed.

NOTE2: In real-time mode, when the preset target force value reaches 90%, the red light flashes after the buzzer is turned on, and the buzzer shortly sounds; after the vibrator is turned on, the red light flashes, the vibrator vibrates intermittently, and the vibration frequencyaccording toTorqueProximity increases vibration frequency

NOTE3: In real-time mode, after the buzzer is turned on, themore than theWhen the target torque value is preset, the red light is on and the buzzer is on; after the vibrator is turned on, the red light is on and the vibrator vibrates continuously.

NOTE4: The buzzer and vibrator cannot be enabled at the same time. If the user turns on the buzzer, the vibrator turns off automatically; if it turns on, the buzzer turns off automatically.

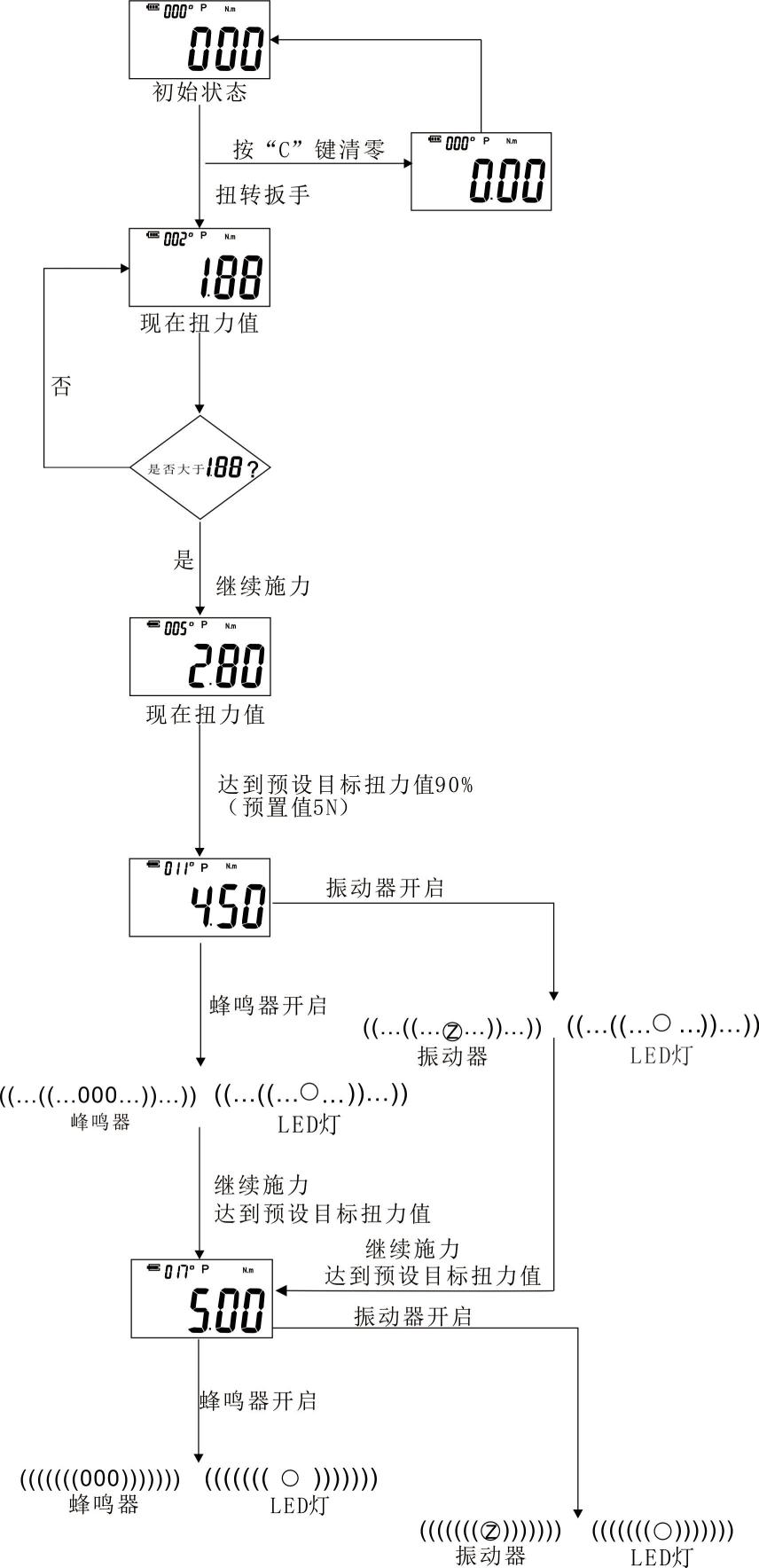

3.3 Peak mode

In peak measurement mode, when torque is applied, the wrench will lock the maximum applied torque and maximum angle, and will其Displayed on the LCD screen. When unloading torque, peak torqueAnd peak angleWill be locked and the LCD screen will be loaded when loaded againLocked peaks will not be updated. When the automatic save function is turned on, the wrench will automatically save the force value and angle, and automatically clear it.需get onIn the next measurement, load torque directly. When the auto save function is not enabled, it can be saved by pressing \"M \" or cleared by pressing \"P / C \".

The LCD screen displays P as the peak mode. If P is not displayed, press\" \"To switch. The operation steps of peak mode are shown in the figure below:

\"To switch. The operation steps of peak mode are shown in the figure below:

NOTE1: In peak mode, when the torque value is greater than 0 during the first measurement, the wrench displays the angle and torque value; but when the force is applied (when the value is not cleared and the value is not saved), the torque value measured this time is greater than the first measurement The angle value will follow the torque value when the force value changes.

NOTE2: In peak mode, when 90% of the preset target torque value is reached, the red light blinks after the buzzer is turned on, and the buzzer sounds shortly; after the vibrator is turned on, the red light blinks and the vibrator vibrates intermittently.

NOTE3: In real-time mode, after the buzzer is turned on, when the preset target torque value is reached, the red light is on and the buzzer is on; after the vibrator is turned on, the red light is on and the vibrator vibrates continuously.

NOTE4: The buzzer and vibrator cannot be enabled at the same time. If the user turns on the buzzer, the vibrator turns off automatically; if it turns on, the buzzer turns off automatically.

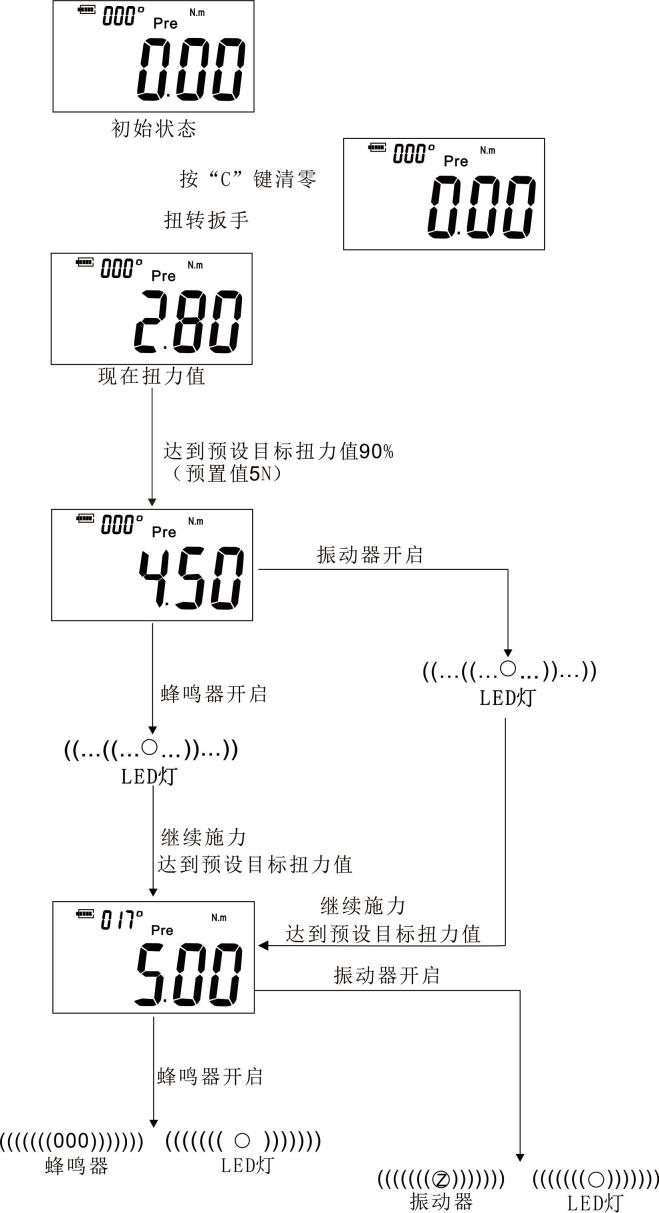

3.4 Preset mode

The preset mode is designed after the torque value reaches the target value, and continues to give the screw a certain angle. When the applied torque value is greater than or equal to the target torque value, the wrench starts to calculate the angle value. When the torque is unloaded, the torque and angle values are automatically locked.

The LCD screen displays Pre as the preset mode. If Pre is not displayed, press\" \"To switch. The operation steps of preset mode are shown in the figure below:

\"To switch. The operation steps of preset mode are shown in the figure below:

NOTE1: In preset mode, the wrench will only display the angle when the preset target torque value is reached.

NOTE2: In the preset mode, when the preset target torque value reaches 90%, the red light flashes.

NOTE3: In preset mode, after the buzzer is turned on, when the preset target torque value is reached, the red light is on and the buzzer is short; after the vibrator is turned on, the red light is on and the vibrator vibrates continuously.

NOTE4: The buzzer and vibrator cannot be enabled at the same time. If the user turns on the buzzer, the vibrator turns off automatically; if it turns on, the buzzer turns off automatically.

4. How to use

4.1 Switch on

Short press the\"\" P / C \"button to turn on the power. If the power display is insufficient after the start, it will be automatically turned off and charged for normal use.

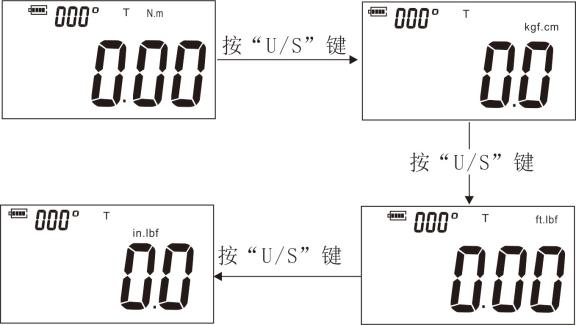

4.2 Unit switching

4.3 Setting preset values

First press \"P / C \" key to boot, press \" \"Key to determine whether the key lock is turned on. If the key lock is turned on, you can turn off the key lock function through \" key lock \"in the system settings (see \" System Settings \"below). Open, it will display the letter \"

\"Key to determine whether the key lock is turned on. If the key lock is turned on, you can turn off the key lock function through \" key lock \"in the system settings (see \" System Settings \"below). Open, it will display the letter \" \", Then you can press \"

\", Then you can press \" \"Key to increase the target value, or press \"

\"Key to increase the target value, or press \" \"Key to decrease the target value. After setting, press \" U / S \"key to save and exit.

\"Key to decrease the target value. After setting, press \" U / S \"key to save and exit.

4.4 Clear

①When the wrench force value is 0, press \"P / C \" key, \" \", Which means that the angle calibration is cleared. AtWhen the angle is cleared, please place the wrench on a flat surface to rest,untilAngle reset completed。

\", Which means that the angle calibration is cleared. AtWhen the angle is cleared, please place the wrench on a flat surface to rest,untilAngle reset completed。

②When the force value of the wrench is displayed, press \"P / C \" to directly reset the force value, The angle is not clear。

4.5 Data saving and viewing

4.5.1 Data storage

① Short press \"M \" on the measurement interface to display \" \"When it means save successfully. WhenWhen the force value is zero, it cannot be saved, it will prompt\"

\"When it means save successfully. WhenWhen the force value is zero, it cannot be saved, it will prompt\" \".

\".

②Auto save: In peak mode and preset mode, when the auto save time is not set to 0 in the system settings, the wrench will automatically save the torque value. When the auto-save time is 0, the wrench will not automatically save the torque value, the user needs to manually press \"M \" to save the torque value.

4.5.2 View saved data

Press \"P / C \" key to boot orUnder the boot measurement interface, Long press \"M \" key, you can view the saved data, inData viewing interface canby,\" \"or\"

\"or\" \"key,View saved records whenAfter viewing, press \"U / S\"Key to exit.

\"key,View saved records whenAfter viewing, press \"U / S\"Key to exit.

4.6 Delete stored data

①On the measurement interface, long press the\"M\" key to enter the data viewing interface, and short press the\"P / C\" key to display \",or\"

\",or\" \", When displayed \"

\", When displayed \" \",thenPress \"U / S \" to display \"

\",thenPress \"U / S \" to display \" \", That means all data is deleted (this instrument cannot delete data one by one).

\", That means all data is deleted (this instrument cannot delete data one by one).

② On the measurement interface, long press the\"M\" key to enter the data viewing interface, press the\"P / C\" key to display \" \", Continue to press \" P / C \"to switch the display \"

\", Continue to press \" P / C \"to switch the display \" \", Then press \" U / S \"to return directly to the measurement interface, indicating that the data will not be deleted.

\", Then press \" U / S \"to return directly to the measurement interface, indicating that the data will not be deleted.

4.7 System settings

4.7.1 Angle setting: the setting range is 0 ~ 999, the user can press \" \"Key and \"

\"Key and \" \"Key to set the value you need. When the angledisplay999 hours,再Adding up will cycle into0,Also when the angle is displayed0时,press\"

\"Key to set the value you need. When the angledisplay999 hours,再Adding up will cycle into0,Also when the angle is displayed0时,press\" \"Key downMinus time, angleWill jump to 999.

\"Key downMinus time, angleWill jump to 999.

4.7.2 Key lock: for preset target torque value. Users can press \" \"Key and \"

\"Key and \" \"Key to set the key lock on or off, \" 1 \"is on, \" 0 \"is off.

\"Key to set the key lock on or off, \" 1 \"is on, \" 0 \"is off.

4.7.3 Auto save time: the settable range is 0 ~ 5 (seconds), 0 means turn off the auto save function. Users can press \" \"Key and \"

\"Key and \" \"Key to set the automatic save time.

\"Key to set the automatic save time.

4.7.4 Buzzer: Set the buzzer on or off. 1 is on, 0 is off. Users can press \" \"Key and \"

\"Key and \" \"Key to set buzzer on or off.

\"Key to set buzzer on or off.

4.7.5 Vibrator: Set the vibrator on or off. 1 is on, 0 is off. Users can press \" \"Key and \"

\"Key and \" \"Key to set the vibrator on or off.

\"Key to set the vibrator on or off.

4.7.6 Auto power off: Auto power off time setting, the setting range is 0 ~ 30 (minutes). 0 is to turn off the automatic shutdown function, the user can press \" \"Key and \"

\"Key and \" \"Key to set the automatic shutdown time you need.

\"Key to set the automatic shutdown time you need.

4.7.7 Restore factory settings: Users can restore the instrument to factory settings through this function. By pressing \" \"Key and \"

\"Key and \" \"Key to select \"

\"Key to select \" \"(Restore factory settings) or \"

\"(Restore factory settings) or \" \"(Do not restore factory settings). If you choose to restore factory settings, choose \"

\"(Do not restore factory settings). If you choose to restore factory settings, choose \" \"After quickly pressing the \" U / S \"key, the LCD screen will appear \"

\"After quickly pressing the \" U / S \"key, the LCD screen will appear \" \"(The factory settings have been restored), and the system automatically returns to the measurement interface. If you choose not to restore the factory settings, select \"

\"(The factory settings have been restored), and the system automatically returns to the measurement interface. If you choose not to restore the factory settings, select \" \"Just.

\"Just.

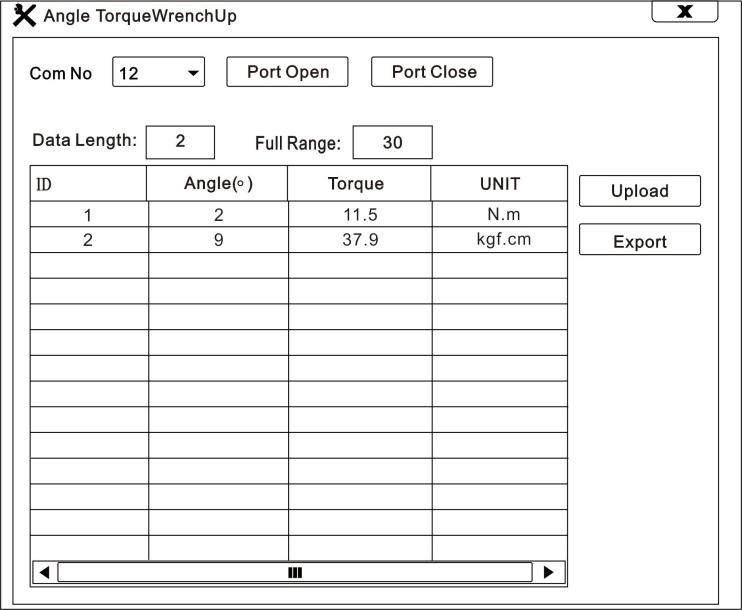

5. Communication and uploading data

This wrench uses USB communication mode, you can upload the saved data to the PC, you can also upload real-time measurement data to the PC.

Use the CD provided by the manufacturer, install the communication software on the computer, and then connect the digital display wrench to the computer with the data cable when the digital display wrench is turned on. Double-click the software icon to open the software. \", Then click \" Part Open \", and then click \" Upload \", then the stored data in the instrument will appear on the table, indicating that the host computer has been successfully connected and the purpose of reading the stored data has been achieved. As shown below:

Communication settings: baud rate 4800, 8 data bits, no parity, 1 stop bit.

Communication format:

3 bytes data header + 1 byte function code + 2 bytes data length + N bytes data length + 1 byte checksum

Data header: 0xEB 0x00 0x55

|

function code |

meaning |

example |

|

F0 |

PC sends a handshake command to the wrench |

Instruction: EB 00 55 f0 00 00 30 |

|

F1 |

Wrench handshake confirmation command to PC |

Return instruction: EB 00 55 F1 00 00 62 |

|

F5 |

The PC requests the wrench to store data |

Instruction: EB 00 55 f5 00 00 35 |

|

01 |

Spanner sends span data |

Return instruction: EB 00 55 01 00 02 00 1E C2 |

|

02 |

Wrench send storage data size |

Return instruction: EB 00 55 02 00 02 00 06 94 |

|

03 |

Wrench send storage data size |

Return instruction: EB 00 55 03 00 12 00 01 00 00 00 04 00 00 00 00 00 02 00 00 00 00 00 00 B8 |

|

04 |

Wrench sending data has been sent |

Return instruction: EB 00 55 04 00 00 88 |

|

FC |

PC requests real-time data |

Instruction: EB 00 55 FC 00 00 3C |

Seven, prompt information

|

Prompt message |

meaning |

Solution |

|

ER-2 |

Abnormal memory |

The memory is full, or the memory is damaged. Clear stored data or return to factory for repair. |

|

ER-3 |

Abnormal sensor or circuit board |

The force value is greater than 5% and the zero point is cleared, and the unloading force value is then reset. If the unloading force value cannot clear the error message, return to the factory for repair. |

|

ER-4 |

Overrange |

If it exceeds 120% of full scale, it will prompt ER-4. After unloading the force value, press [P / C] to clear the error. |

|

SUCC |

Prompt operation completed |

After an operation is completed, it returns automatically. |

|

Fail |

Prompt operation failed |

An operation fails and returns automatically. |

8. Maintenance and storage

8.1 Note:

In order to maintain good accuracy, it is recommended to recalibrate once every year.

8.2 Excessive torque may cause damage or loss of accuracy (more than 105% of the maximum torque range).

8.3 Do not shake the wrench violently or drop the wrench on the ground.

8.4 Do not use the wrench as a hammer.

8.5 Do not place the wrench in high temperature, high humidity or direct sunlight.

8.6 Do not use wrenches near water.

8.7 If you accidentally get the wrench wet, wipe it dry with a dry towel immediately. Salt in the sea water may damage the wrench.

8.8 Do not use organic solvents to clean the wrench, such as alcohol or paint thinner.

8.9 Do not put the wrench near magnetic objects.

8.10 Do not place the wrench in a place where there is a lot of dust or sand. This will cause serious damage to the wrench.

8.11 Do not stress the LCD screen.

Nine, random accessories

|

1 |

With angleDigital torque wrench (pre-installed ratchet head) |

1 |

|

2 |

lithium battery |

1 knot |

|

3 |

Instructions |

1 serving |

|

4 |

Battery cover key |

1 |

|

5 |

Certificate of conformity |

1 serving |

|

6 |

Warranty Card |

1 serving |

|

7 |

Inspection certificate |

1 serving |

|

8 |

Desiccant |

1 package |

|

9 |

PC installation CD |

1 |

|

10 |

Charger + data cable |

1 set |