I. Overview

1.1 Main uses and scope of application

Economic torque tester is a precision measuring instrument used to detect and test and calibrate various torques. It is used to detect and calibrate various electric screwdrivers, torque screwdrivers, torque wrenches. Various products involve the test of tightening force, and the parts are damaged by torsion Sex test, etc. Widely used in electrical manufacturing, machinery manufacturing, automotive light industry, professional scientific research and testing industries.

1.2 Product features

1.2.1 Accuracy ± 1%.

1.2.2 Four units: N.m, kgf.cm, ft.lbf, in.lbf.

1.2.3 The test modes include peak hold, first peak and real-time mode.

1.2.4 USB communication function, data format adopts Modbus communication.

1.2.5 Can be automatically shut down at a preset time.

1.2.6 Buzzer and LED warning.

1.2.7 Preset target value function: target value and target value tolerance range can be preset.

1.3 Product specifications

|

model |

unit |

ANL-1B |

ANL-2B |

ANL-5B |

ANL-10B |

ANL-20B |

|

Torque measurement Range |

N.m |

0.1000 ~ 1.0000 |

0.200 ~ 2.000 |

0.500 ~ 5.000 |

1.000 ~ 10.000 |

2.00 ~ 20.00 |

|

kgf.cm |

1.0197 ~ 10.197 |

2.039 ~ 20.39 |

5.098 ~ 50.98 |

10.197 ~ 101.97 |

20.39 ~ 203.9 |

|

|

ft.lbf |

0.07375 ~ 0.7375 |

0.1475 ~ 1.475 |

0.3687 ~ 3.687 |

0.7375 ~ 7.375 |

1.475 ~ 14.75 |

|

|

in.lbf |

0.8850 ~ 8.850 |

1.770 ~ 17.70 |

4.425 ~ 44.25 |

8.850 ~ 88.50 |

17.70 ~ 177.0 |

|

|

Index value |

N.m |

0.0001 |

0.001 |

0.001 |

0.001 |

0.01 |

|

kgf.cm |

0.001 |

0.01 |

0.01 |

0.01 |

0.1 |

|

|

ft.lbf |

0.0001 |

0.001 |

0.001 |

0.001 |

0.01 |

|

|

in.lbf |

0.001 |

0.01 |

0.01 |

0.01 |

0.1 |

|

|

Accuracy |

± 1% |

|||||

|

Transmission function |

Support USB transmission |

|||||

|

Operating mode |

First peak / real-time mode / peak hold |

|||||

|

Unit selection |

N.m / kgf.cm / ft.lbf / in.lbf |

|||||

|

Operating temperature |

5 ℃ ~ 40 ℃ |

|||||

|

Storage temperature |

-20 ℃ ~ 70 ℃ |

|||||

|

humidity |

90% without condensation |

|||||

|

power supply |

7.4V lithium battery |

|||||

|

charger |

Input: AC 220V 50HZ Output: DC 12V 300 / 500mA |

|||||

|

Weight (Kg) |

1.58 |

|||||

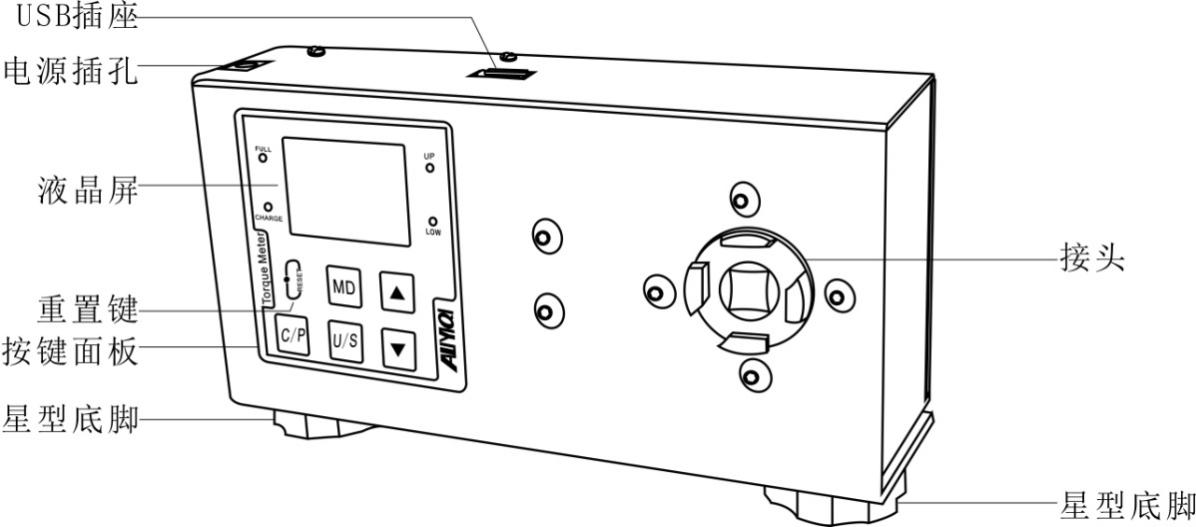

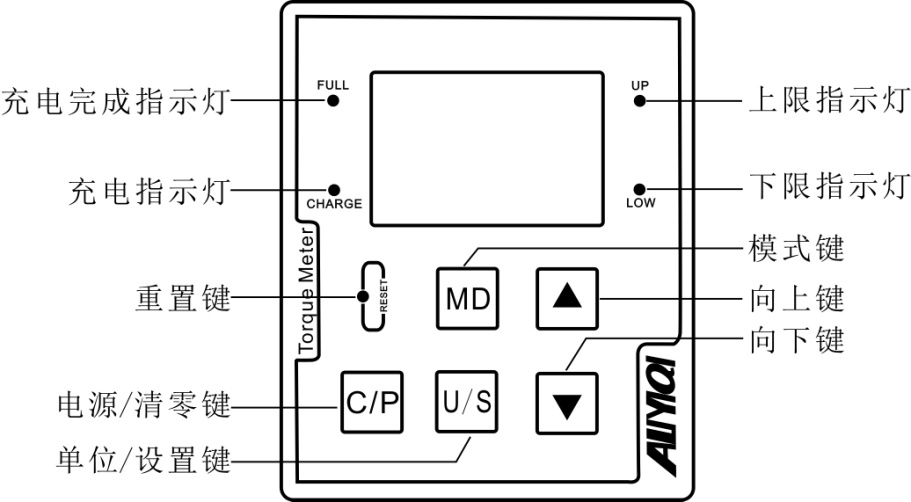

Second, the overall product structure

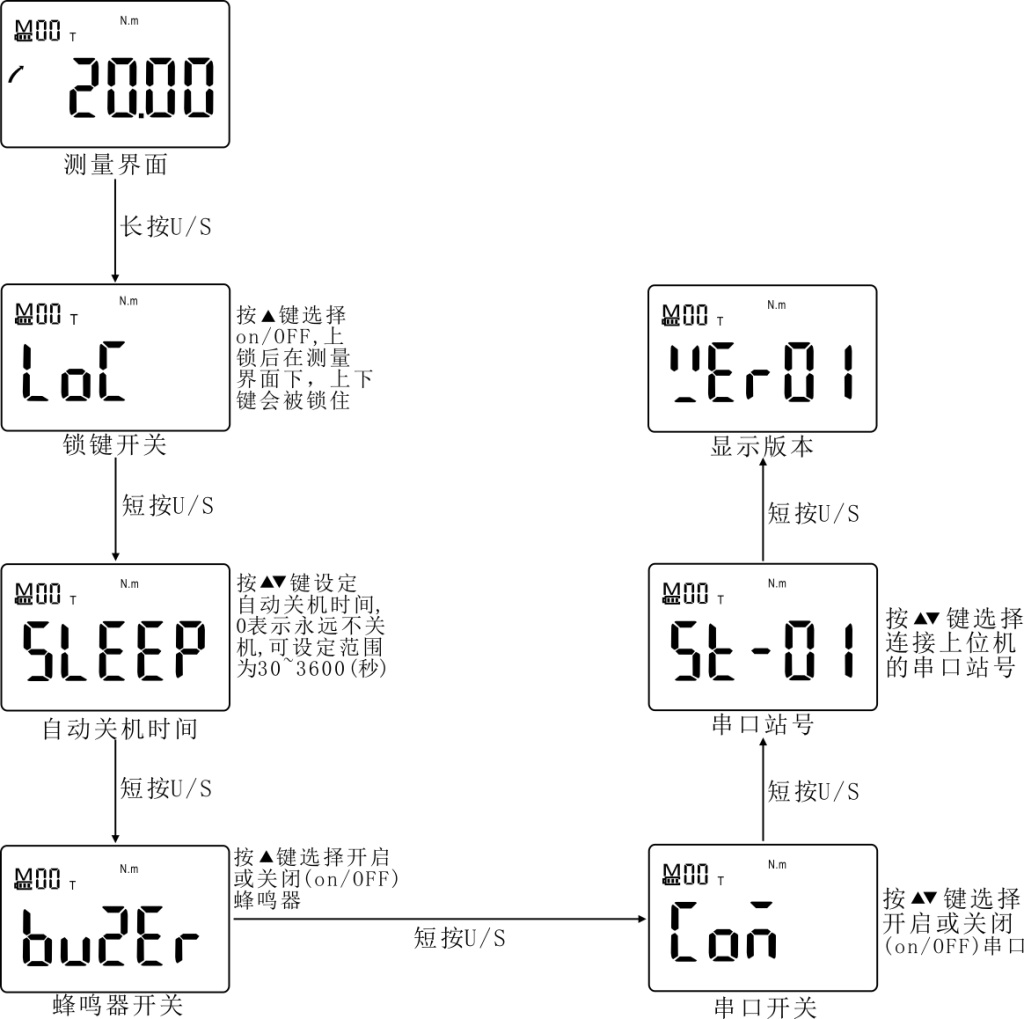

Three, menu function introduction

3.1 System function settings

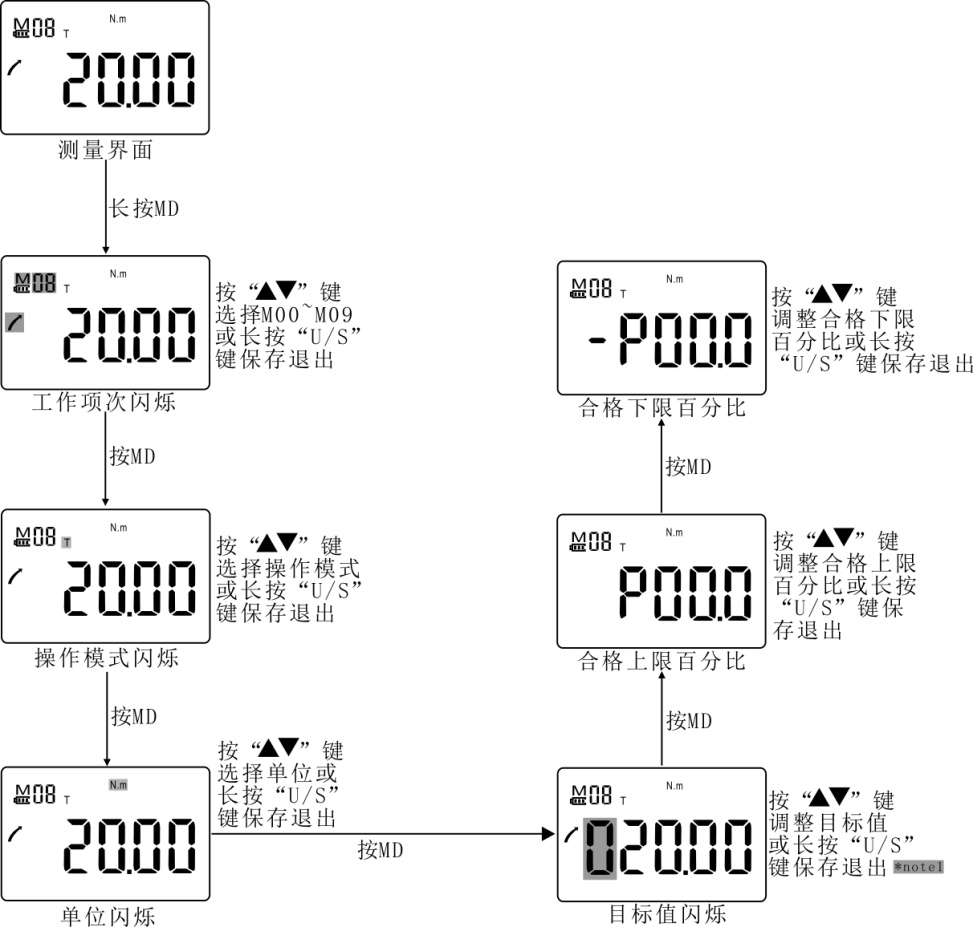

3.2 Preset work item settings

* NOTE1: If the target value is set to full scale (for example, full scale is 20), the upper limit percentage cannot be set, and the target value must be between the upper limit and the lower limit.

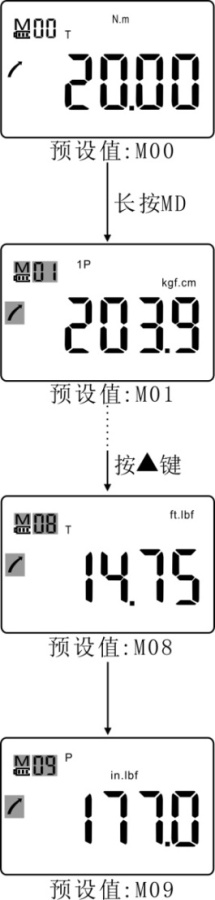

3.3 Select preset work item

3.4 Select torque unit

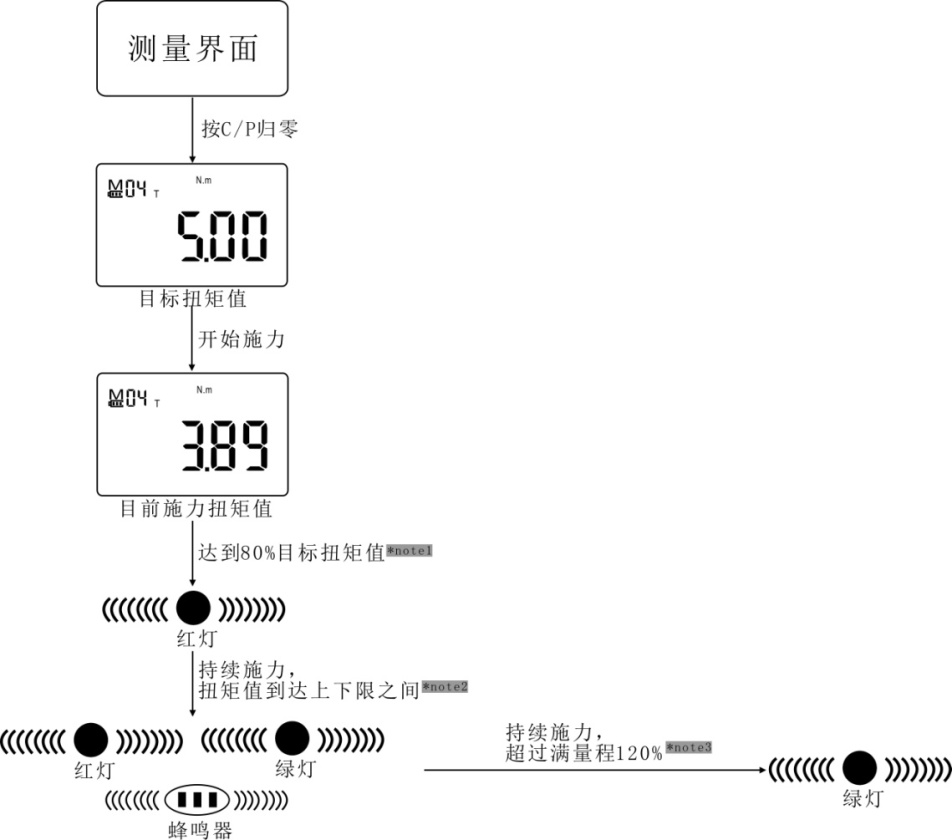

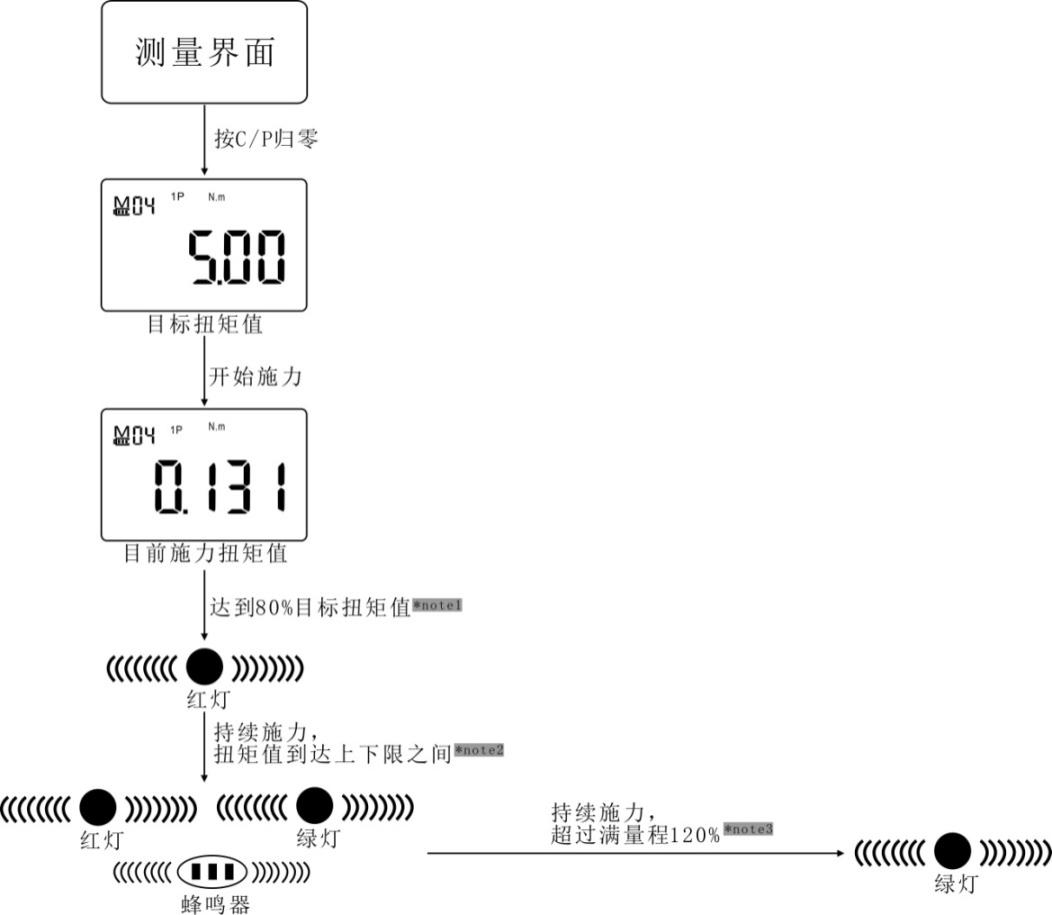

3.5 Operation steps in real-time mode

* Note1: When the applied torque value reaches 80% of the target torque value, \"LOW \" red light is on.

* Note2: When the applied torque value reaches the qualified torque value (higher than the lower limit value and lower than the upper limit value), the green lights of\"UP\" and the red lights of\"LOW\" will be on and the buzzer will sound.

* Note3: When the applied torque value exceeds the upper limit, the green light of\"UP\" will be on continuously.

* Note4: When the applied torque value exceeds 120% of full scale, the green light of\"UP\" will be on continuously.

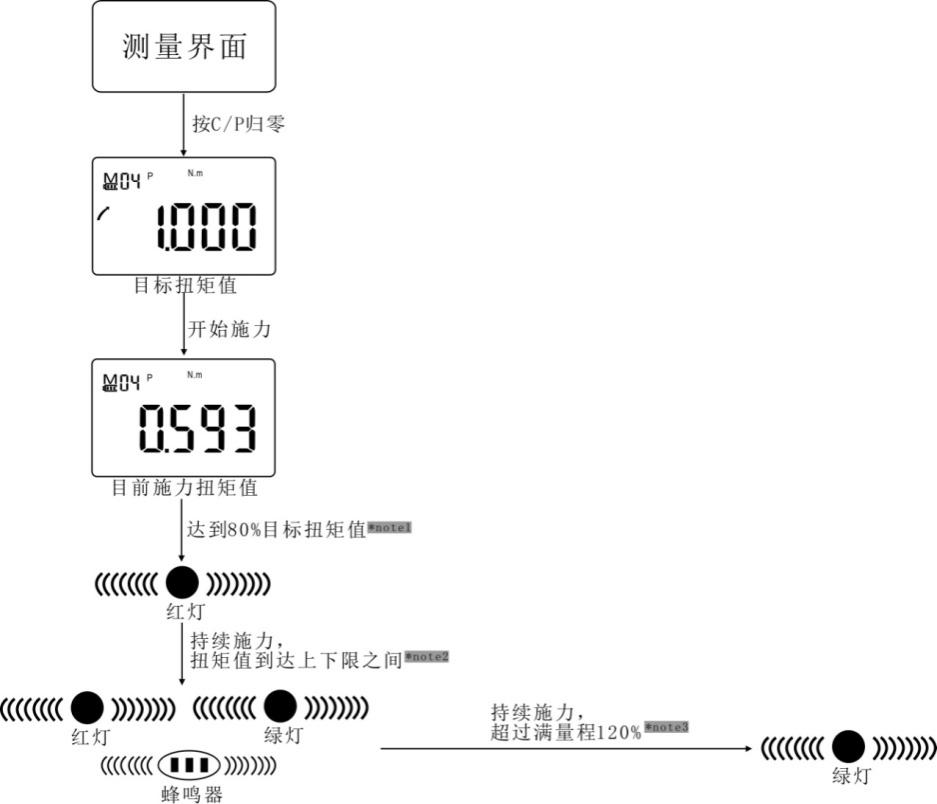

3.6 Peak mode operation steps

* Note1: When the applied torque value reaches 80% of the target torque value, \"LOW \" red light is on.

* Note2: When the qualified torque value is reached (higher than the lower limit value and lower than the upper limit value), \"UP \" green light and \"LOW \" red light are on and the buzzer sounds.

* Note3: When the torque value exceeds the upper limit, \"UP \" green light is on.

* Note4: When 120% of full scale is exceeded, the green light of\"UP\" will be on.

3.7 Operation steps of the first peak mode

* Note1: When the applied torque value reaches 80% of the target torque value, \"LOW \" red light stays on.

* Note2: When the qualified torque value is reached (higher than the lower limit value and lower than the upper limit value), \"UP \" green light and \"LOW \" red light are on and the buzzer sounds.

* Note3: When the torque value exceeds the upper limit, \"UP \" green light is on.

* Note4: When the full range exceeds 120%, the green light is on.

4. Communication

In order to facilitate the customer's need for convenient communication, the instrument uses Modbus protocol to communicate with the host computer. Users can communicate with the instrument's host computer software (non-standard configuration) or modbus general software to communicate with the instrument.

The communication format is as follows:

Real-time data: Modbus 3x address: 00 32BIT Float

Range: Modbus 3x Address: 02 32BIT Float

Working mode unit: Modbus4x address 02 16BIT BIT high 8-bit working mode low 8-bit unit

5. Maintenance and storage

5.1 In order to maintain good accuracy, it is recommended to recalibrate once every year.

5.2. Use exceeding the full-scale value may cause damage to this product or loss of accuracy (more than 110% of the full-scale torque value).

5.3 Do not use the torque tester as a percussion tool.

5.4. Please make sure all components are connected correctly before use.

5.5. Do not press the LCD screen heavily.

5.6 Do not use organic solvents to clean the tester, such as alcohol or paint thinner.

5.7 Do not use unauthorized sockets or accessories.

5.8 Do not attempt to disassemble or repair this tester, otherwise the tester may be damaged.

5.9. When not using the tester, this product should be stored in an appropriate location.

5.10. Do not touch the power plug with wet hands to avoid the possibility of electric shock.

V. Random accessories

|

1 |

Economic torque tester |

1 set |

|

2 |

buffer |

1 set |

|

3 |

Power Adapter |

1 |

|

4 |

user's Guide |

1 copy |

|

5 |

Product inspection certificate |

A copy |

|

6 |

Product Certificate Warranty Card |

One |

|

7 |

M3 Allen wrench |

1 |