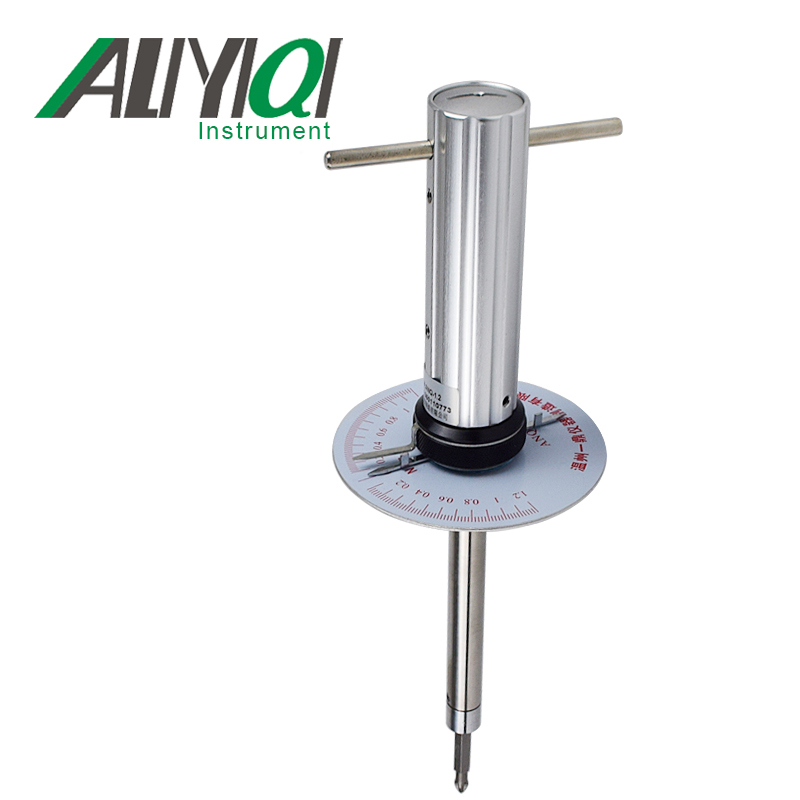

1. Performance:

The pointer torque screwdriver is a new product developed by our company that is suitable for the automotive, motorcycle, machinery manufacturing, electronics and other industries, as well as the professional testing industry. It is mainly used for the tightening and tightening force detection of components with moderate torque It is easy to hold and operate, easy to use, and maintains clarity for a long time. It is a tool for assembling and maintaining the equipment and testing the performance of the tightening parts.

2. Features:

1. Dial pointer indication: the pointer indicates the torque value, the reading is convenient, accurate and high precision.

2. There is a driven needle: when the customer rotates to the corresponding measured value, the driven needle stops and it is convenient for the customer to read the accurate measured value.

3. It can be twisted left and right: the product can rotate clockwise or counterclockwise.

4. Reasonable design: hand-held operation, long-term use without fatigue.

5. Easy operation: As long as the zero position is aligned, anyone can operate and use it in the same way.

6. A screwdriver head with a cross and a flat head is attached, allowing customers to replace the screwdriver head according to the items they want to measure.

7. There is a stiffener, when customers use a large range of torque drivers, they can better operate this product.

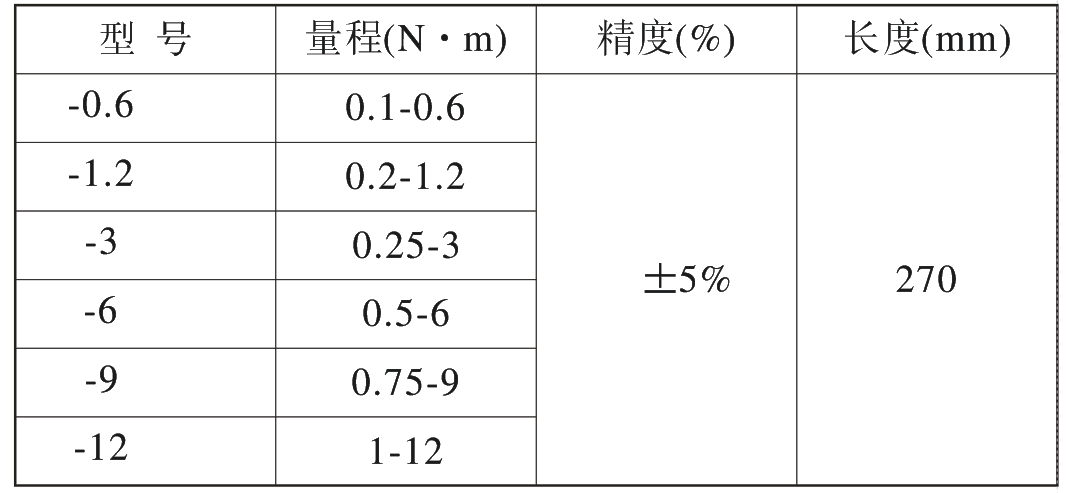

3. Product size:

Length (L): 270 (mm)

Width (W): 98 (mm)

High (H): 100 (mm)

4. Various models:

5. How to use:

1. The zero must be adjusted before use, so as to ensure the measurement accuracy of this product. The specific zero adjustment method is as follows:

(1): Loosen the lock nut on the torque driver, turn the dial to align the fixed pointer to the zero position, and then tighten the lock nut on the torque driver;

(2): After aligning with the zero position, if you need to measure clockwise, gently twist the handle clockwise, and then release it naturally to align the fixed pointer with the zero position of the dial. If the zero position is not aligned, align the fixed pointer to the zero position again according to the first method. After aligning with the zero position, it can be turned clockwise.

(3): After aligning with the zero position, if you need to measure counterclockwise, gently twist the handle counterclockwise and then loosen naturally to align the fixed pointer with the zero position of the dial. If the zero position is not aligned, the fixed pointer is aligned with the zero position again according to the first method. After aligning with the zero position, it can be turned counterclockwise.

2. During use, this product must be kept in a vertical state with the items to be measured by the customer, otherwise it will reduce the measurement accuracy of this product and will also reduce the service life of this product.

3. After use, adjust to zero position for future use.

Six, matters needing attention:

1. This product is only suitable for tightening and testing within the calibration range, and is not allowed to be used as other tools.

2. The measured value of this product has been corrected, it is not allowed to open the back cover, and loosen the set screw on the product, so as not to cause errors in the measurement accuracy.

3. This product should not be in contact with acids, alkalis and corrosive gases.

Special Note:

There are many specifications of pointer torque screwdrivers for users to choose. Users can choose instruments of corresponding specifications according to the force value of the desired test product. The scientific test range is 10% to 100% of full scale, and the metrology department recommends not to use less than 1% of full scale.

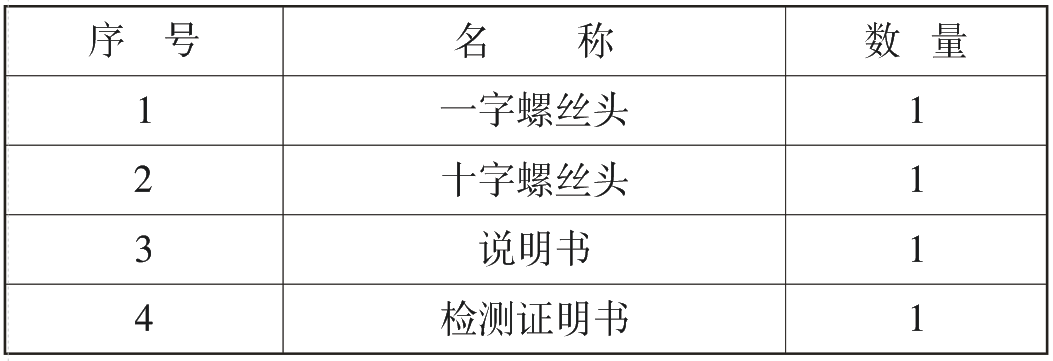

Six, packing list

Dear Customer:

Hello! Thank you very much for choosing our company's pointer torque screwdriver. When you buy, please check whether the accessories are complete.