一、Overview

1.1、AQBH digital torque meter is used for measurement, observation and tightening in a small range. The direct digital reading is easy to adjust to the appropriate torque value. The three-jaw keyless assembly is more suitable for clamping the tested product.In peak working mode, with automatic and manual storage100Group torque peak function,The time for automatically storing the torque peak value can be selected and set within the time range of (0.0 ~ 4) seconds;It can be directly connected to the computer through the USB data line for communication, and the stored data can be downloaded, viewed, analyzed, backed up, deleted, and printed out through the host computer software.

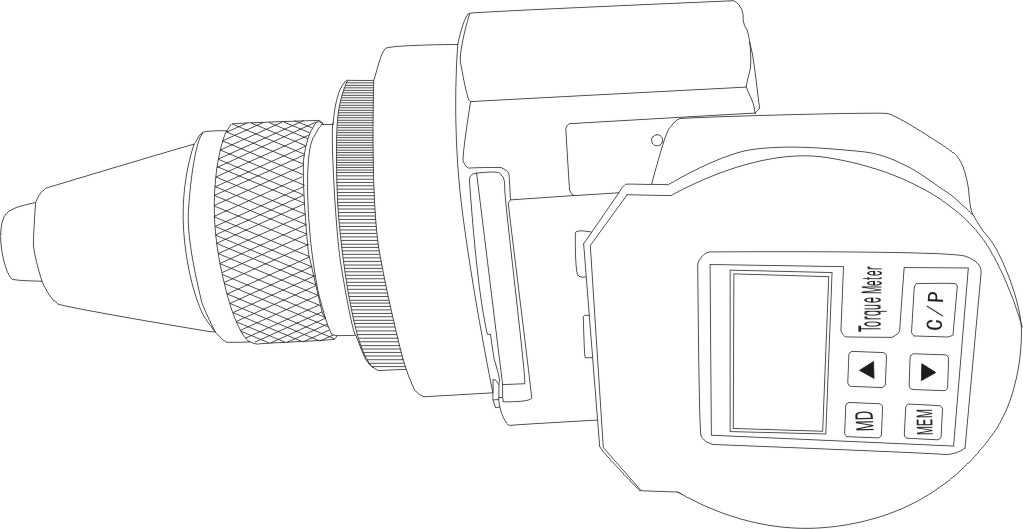

Second, the shape and structure

2.1 Basic structure

①Three claws

The three-jaw device can freely tighten and loosen with the tightening and loosening of the thread, and clamp the measured object.

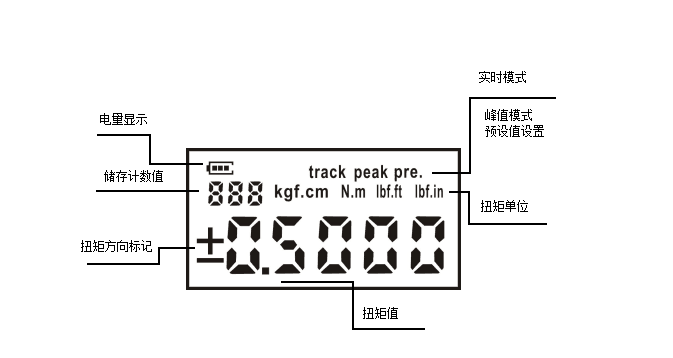

②LCD Monitor:

The 4-digit LCD display includes power display, two working modes, preset value setting, torque unit, torque value, torque direction mark, and stored count value.

③USB communication interface

Connect a computer to transfer data, and connect a charger to charge the battery.

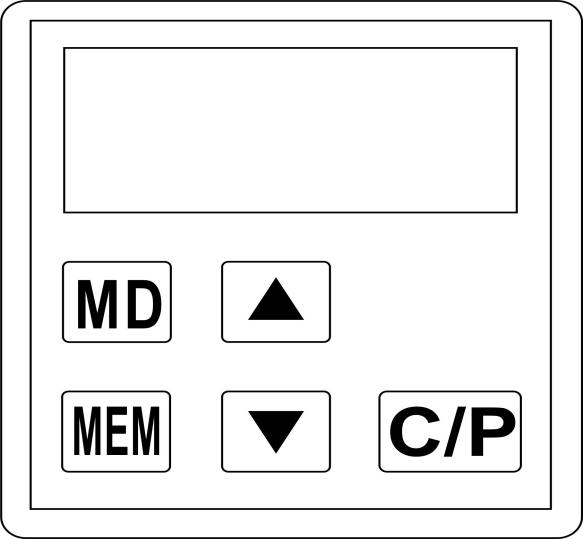

④Button panel

Key panel includes 、

、 、

、 、

、 、

、 Five buttons

Five buttons

: Flip up to store data,Change settings.

: Flip up to store data,Change settings.

: Enter data view mode, scroll down to store data,Switch the interface and change the settings.

: Enter data view mode, scroll down to store data,Switch the interface and change the settings.

:dataStore, switch or save when setting parameters.

:dataStore, switch or save when setting parameters.

: Switch the working mode.

: Switch the working mode.

: On / off, confirm zero,delete data.

: On / off, confirm zero,delete data.

%1,Features

Features include: mode settings、Numerical storage(automatic/Manual)、Data cleanup、data communication.

3.1、Torque reading

3.2、Accuracy±2%

3.3、Can operate clockwise and counterclockwise

3.4、Real-time measurement mode (track), peak mode (peak), save peak calculation mode (pre)

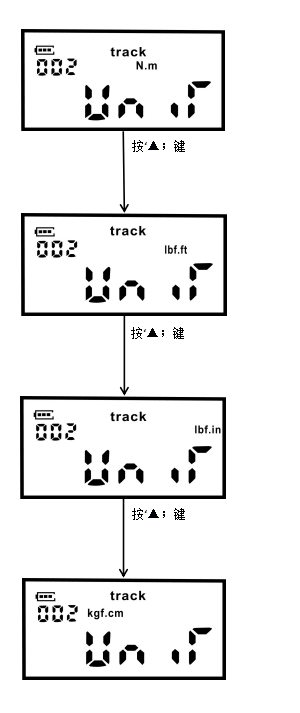

3.5、Unit: N.m,lbf.ft,lbf.in,kgf.cm four engineering unitsAvailable for selection and conversion.

3.6、Data storage function, can store 100 test values, The 3 digital tubes in the upper left corner show the amount of data currently saved.

3.7、Communication function

3.82. You can set the automatic shutdown to the required automatic shutdown time. When the automatic shutdown is set to 0, the automatic shutdown will not be performed.

3.9、With charging function

%1,Technical Parameters

4.12. Power supply: Lithium battery, equipped with charger, which can be charged through USB communication interface;

4.22. The battery has low power consumption and has the function of automatic detection of battery power;

4.3.Can operate clockwise and counterclockwise;

4.4, Can be stored in peak mode100Group torque value;

4.53. Operating environment: temperature (0 ~ 40) ℃, humidity ≤85%;

4.61. Storage environment: (-10 ~ 60) ℃.

%1,Instructions

|

model |

量程 (N.m) |

Index value (N.m) |

Accuracy |

Nominal size of inner six parties |

net weight (Kg) |

Clamping range |

||||

|

inch |

mm |

mm |

||||||||

|

AQBH-0.5 |

0.1-0.5 |

0.0001 |

±2% |

1/4 |

6.35 |

0.8 |

1-8 |

|||

|

AQBH-1 |

0.2-1 |

0.001 |

±2% |

1/4 |

6.35 |

|||||

|

AQBH-2 |

0.4-2 |

0.001 |

±2% |

1/4 |

6.35 |

|||||

5.1. Operating instructions

P / C: boot and reset button

MD: Mode switch

MEN: data storage, setting window switching, pre data viewing

Up Arrow / Down Arrow: Change settings, flip up and down to store data

① Press and hold the power button for 2 seconds to power on and initialize the system

② In Track mode: data measurement is possible,

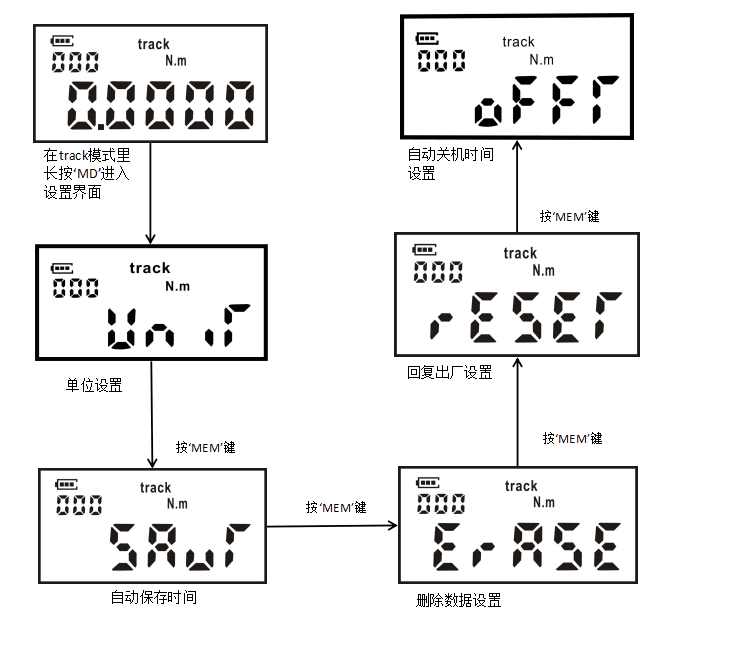

Data cannot be saved in current mode, long press MD key to enter setting mode

③Setting mode

1、Press MEN to switch, press MD to exit the setting mode and return to Track mode,UNIT unit setting press up and down key to switch

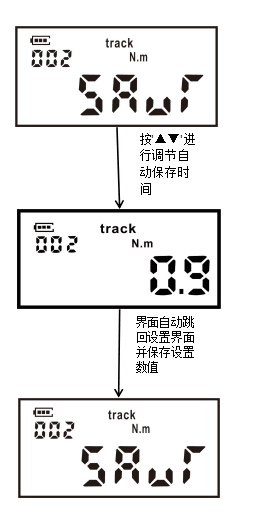

2、SAUT Peak mode automatically saves the data time setting, when set to 0, it is manually saved(Press the MEM keysave), Press the up and down keys to set the time MAX is 4 seconds,saveData can be saved100 groups。

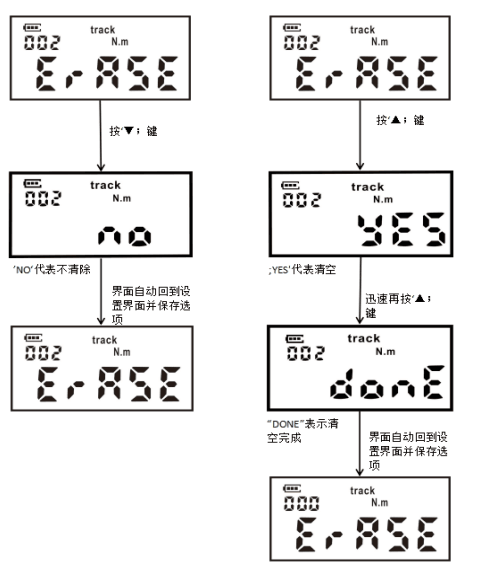

3、ERASE Delete all data. The operation is to press the up key twice (the screen first displays YES and displays done) and the upper left corner of the digital tube is cleared (when the number becomes 000), all the data has been deleted

4、RESET to restore factory settings Same as above (ERASE)

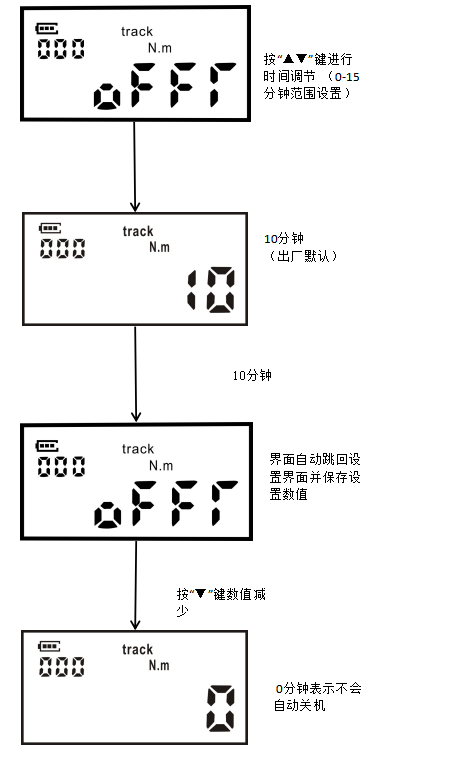

5、OFFT Automatic shutdown time setting, press the up and down keys to set

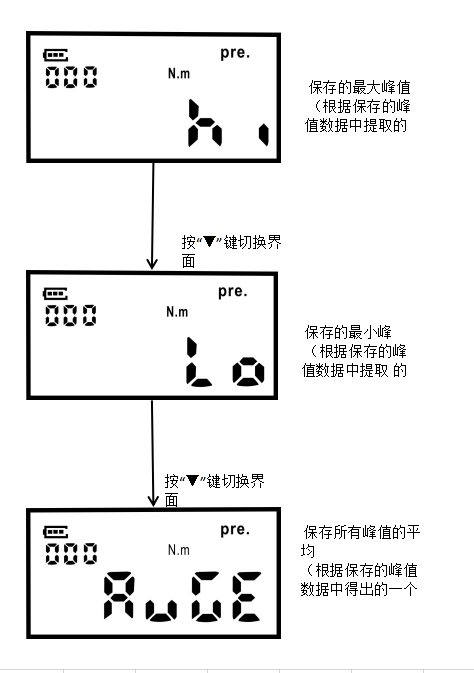

④ Track mode short press MD to switch to pre mode, up and down keys to switch interface, MEN to view data

There are three interfaces in Pre mode:

1、HI:Saved MAX peak

2、LO: saved MIN peak

3、AVGE: save the average of all peaks

Remarks:The data viewed in pre mode without positive and negative directions is Absolute value

⑤ PEAK mode: In this mode, when the SAUT time period> 0, the measurement data will be automatically saved. The time period for saving can be set in the setting mode.

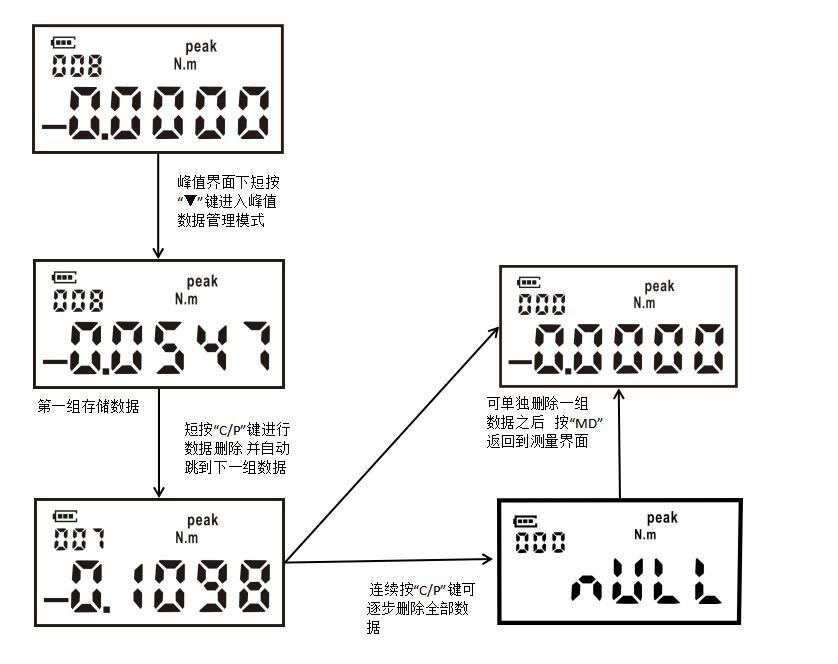

⑥ 在PEAK (In the peak value mode, press the down key to enter the peak data viewing interface, and use the down or up keys to view each set of data. P / C key can delete the current data. MD key to return to peak mode。

5.2. Working parameter setting

5.2.1. Setting items

5.2.2 Unit setting

5.2.3 Automatic save time

5.2.4 Clear data

5.2.5 Delete a single set of data

5.2.6 Automatic shutdown time

5.2.7 Peak average

5.3, Data output

The stored data can be transferred to the computer through the USB port, and data processing can be realized with the software produced by the manufacturer.

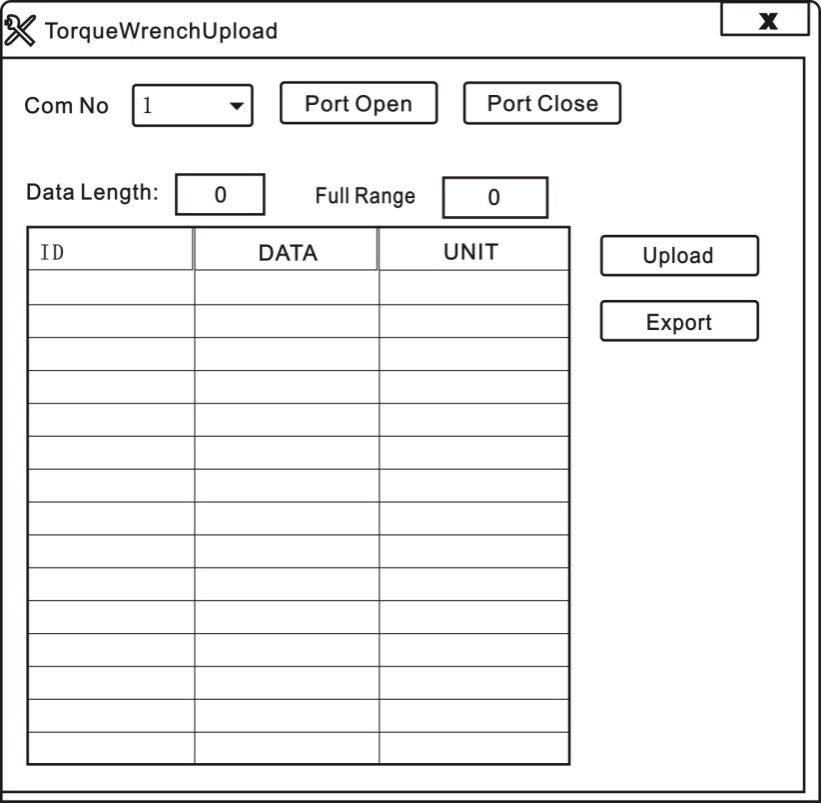

The software interface is as follows:

Use the CD provided by the manufacturer, install the communication software on the computer, and then use the digital display torque表Connect digital torque with data cable when power on表With the computer, double-click the software icon to open the software, select \"Com No (port number) \", then click \"Port Open \", and then click \"Upload \" Stored data indicates that the host computer has been successfully connected and the purpose of reading stored data has been achieved.

Sixth, repair and maintenance

In order to ensure the accuracy of the product, the product should be regularly verified to ensure its normal use.

①Verification requirements:

According to the use frequency requirements of the product, determine the verification period.

②Verification period:

The verification period is generally 12 months, and the verification period for frequently used products is 6 months. Bolts and nuts tightened in important positions should be verified before each use to ensure their accuracy.

③Qualification:

The verification personnel are manufacturers or professionally qualified measurement personnel, and the verification equipment is a verification instrument with a system error of less than or equal to 0.3%.

④Don't use it as a hammer during use, try to avoid knocking and falling.

⑤It is strictly forbidden to use it to avoid damage to the sensor of the product.

⑥It is strictly forbidden to disassemble the product at will. If you encounter problems, please contact our company in time.

⑦After using the product, it should be placed in the box.

Seven, random accessories

|

1 |

Digital torque meter |

1 |

|

2 |

Instructions |

1 serving |

|

3 |

Certificate of conformity |

1 serving |

|

4 |

Desiccant |

1 package |

|

5 |

Android phone data cable |

1 |

|

6 |

5V charger |

1 |