I. Overview

1.1 Main uses and scope of application

This type of torque screwdriver is suitable for thread tightening with fixed torque. It can tighten the workpiece to the specified torque. Mainly used for high-precision thread connection, widely used in automobiles, motorcycles, machinery manufacturing, electronics (mobile phone circuit board installation) and other industries. It is a tool for assembling and maintaining complete equipment and testing the performance of rotating parts. This instrument complies with GB / T 15729-2008 national standard.

1.2 Product features

1.2.1 Universal bit, easy to load and unload standard bit;

1.2.2 Can operate clockwise and counterclockwise in both directions;

1.2.3 Preset torque value;

1.2.4 Screwdriver idling when it exceeds the preset value;

1.2.5 The preset torque value can be locked.

1.3 Specifications

|

model |

Torque adjustment range |

Overall length mm |

Weight g |

Accuracy |

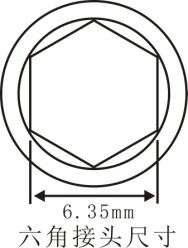

Joint size mm |

Applicable fasteners |

|

|

Min ~ Max (kg.cm) |

Indexing |

Screws |

|||||

|

AQTH6 |

1 ~ 6 |

0.05 |

128 |

130 |

± 5% |

6.35 (Hexagon) |

M2.5, M3 |

|

AQTH12 |

2 ~ 12 |

0.1 |

M3, M4 |

||||

|

AQTH26 |

6 ~ 26 |

0.2 |

155 |

320 |

M4 |

||

|

AQTH50 |

10 ~ 50 |

0.5 |

M5, M6 |

||||

Second, the overall product structure

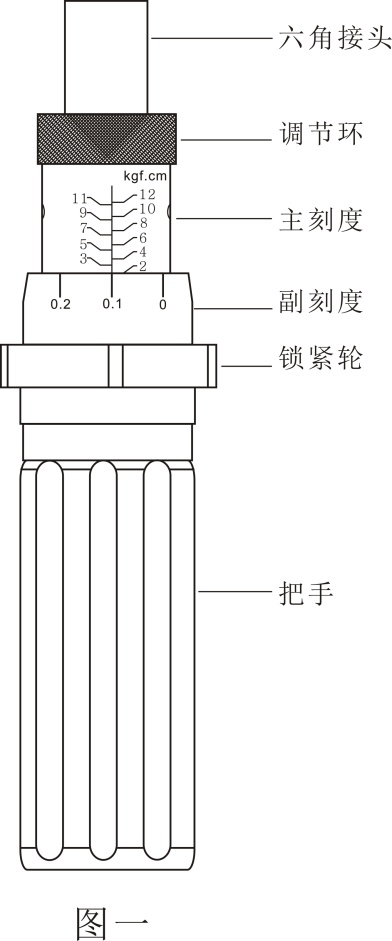

2.1 Shape and structure

3. Use and operation

3.1 Operation and instructions in use

3.1.1 Select the appropriate torque driver according to the torque range required when the fastener is tightened.

3.1.2 Set the torque value of the torque driver according to the torque required for tightening the fastener; turn the locking wheel in the opposite direction of \"LOCK\" to unlock (the scale lines of the main scale and auxiliary scale must be as shown in Figure 1 Only when the display is aligned, can it be turned and unlocked in the opposite direction of \"LOCK\". Loosen the adjustment ring, and adjust the position of the adjustment ring by hand or the attached hook wrench. The working torque value is the main scale indication + subscale indication . As shown in Figure 1, the torque value is: 2 + 0.1 = 2.1kg.cm. After completing the setting, turn the locking wheel to lock in the direction marked with \"\" LOCK \"\" (the scale lines of the main scale and sub-scale must be aligned as shown in Figure 1 before turning and locking in the direction of \"LOCK\") .

3.1.3 According to the form of the head of the fastener (cross, straight, plum, etc.), select the appropriate bit from the attachment and insert it into the hexagonal joint of the head of the torque driver.

3.1.4 Hold the handle and align the bit with the fastener, and turn the torque screwdriver until the tightening torque of the fastener reaches the set value. The torque screwdriver forwards the sound signal empty, accompanied by obvious hand vibration, prompting to complete the operation .

Four, maintenance and warranty

4.1 Confirm the torque range of the torque screwdriver before use, do not use it beyond the range.

4.2 Do not disassemble or modify the torque driver yourself.

4.3 Please use the tool normally, do not drop, press or replace it as other tools.

4.4 Do not engage in underwater operations or contact with water.

4.5 When this tool forwards voice signals empty, please stop tightening the fasteners.

4.6 Please store the tool in a clean place and keep it properly.

4.7 If not used for a long time, please adjust the torque value of the torque driver to the minimum.

5. Warranty

The company will provide free maintenance if the customer has a small quality problem within one year after the purchase. If the problem occurs one year later or if the problem is caused by human factors within one year, the company will provide maintenance and the customer will bear the relevant costs.

Six, packing list

|

Numbering |

name |

Quantity |

|

1 |

Packing box |

1 |

|

2 |

body |

1 |

|

3 |

First batch |

2 |

|

4 |

Product Manual |

1 |

|

5 |

Product certificate and warranty card |

1 |

|

6 |

Desiccant |

1 |

|

7 |

Hook wrench (optional) |

1 |