I. Overview

1.1 Main uses and scope of application

Digital display torque wrenches are different from general torque wrenches and have powerful operating functions, including torque setting; unit setting; mode setting; value storage; value clearing; value output and user correction function. It is easy to operate, and the requirement for the operator is reduced by installing a digital display. It is suitable for bolt tightening and control in automobile industry and machinery industry.

1.2 Features

1.2.1 Digital display torque reading

1.2.2 Clockwise ± 2%, counterclockwise ± 2.5% accuracy (20 ~ 100% of maximum operating range)

1.2.3 Both clockwise and counterclockwise operation

1.2.4 Peak hold and real-time mode

1.2.5 Buzzer and LED indication (when the predetermined torque value is reached)

1.2.6 Four engineering units (ft.lb, in.lb, N.m, kgf.cm)

1.2.7 100 records can be stored

1.2.8 Communication function

1.2.9 Automatic shutdown in 5 minutes

1.3 Product model selection

①: The highest accuracy

|

Accuracy |

|

± 2% -clockwise / ± 2.5% -counterclockwise |

②: Whether with communication function

|

Communication transmission function |

|

|

无 |

无 |

|

R |

有 |

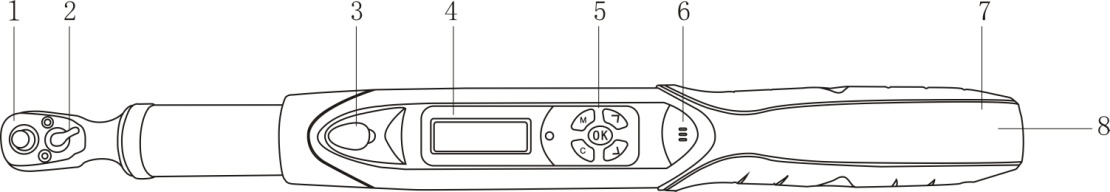

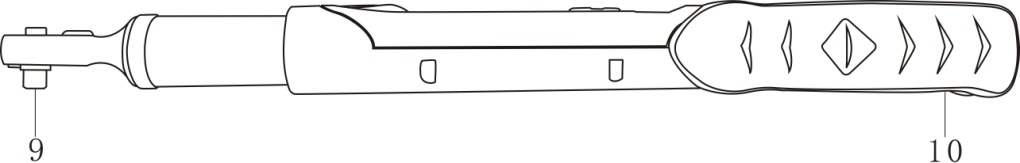

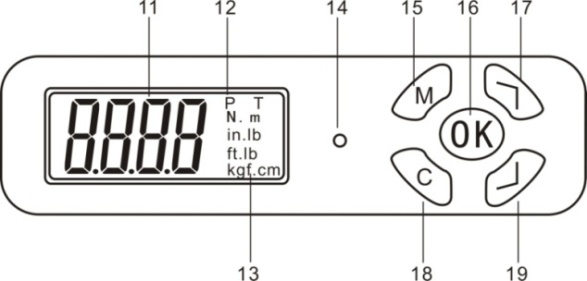

2. Function and name of each component

1. Two-way ratchet head 11. Torque value

2. Steering paddles 12, P (peak mode), T (real-time mode)

3. Communication hole 13. Unit (N.m, in.lb, ft.lb, kgf.cm)

4. LCD screen 14. LED indicator

5. Button 15. Menu button

6. Buzzer 16. Confirm button

7. Battery box 17. Up button

8. Battery cover 18. Cancel button

9. Ratchet torque square head 19. Down button

10. Grip

3. Product Technical Specifications

|

model |

Without communication |

-0010 |

-0030 |

-0030 |

-0060 |

-0085 |

-0135 |

-0135 |

-0200 |

-0340 |

-0500 |

-0850 |

||||||

|

With communication |

-0010R |

-0030R |

-0030R |

-0060R |

-0085R |

-0135R |

-0135R |

-0200R |

-0340R |

-0500R |

-0850R |

|||||||

|

Minimum division value |

0.01 |

0.1 |

||||||||||||||||

|

Maximum operating range (N.m) |

10N.m / 7.37ft.lb/88.50in.lb/101.97kgf.cm |

30N.m / 22.12ft.lb/265.5in.lb/305.91kgf.cm |

30N.m / 22.12ft.lb/265.5in.lb/305.91kgf.cm |

60N.m / 44.25ft.lb/531.04in.lb/611.82kgf.cm |

85N.m / 62.69ft.lb/ 752.31in.lb/866.75kgf.cm |

135N.m / 99.57ft.lb/1195in.lb/1376.61kgf.cm |

135N.m / 99.57ft.lb/1195in.lb/ 1376.61kgf.cm |

200N.m / 147.5ft.lb/ 1770in.lb/ 2039.43kgf.cm |

340N.m / 250ft.lb/ 3009in.lb/ 3467.03kgf.cm |

500N.m / 4424in.lb/ 368.7ft.lb/ 5098.58kgf.cm |

||||||||

|

Connector (inches) |

1/4 |

3/8 |

1/2 |

3/4 |

||||||||||||||

|

Buzzer setting range (N.m) |

0.5 ~ 10 |

1.5 ~ 30 |

1.5 ~ 30 |

2 ~ 60 |

4.25 ~ 85 |

6.75 ~ 135 |

6.75 ~ 135 |

10 ~ 200 |

17 ~ 340 |

25 ~ 500 |

42.5 ~ 850 |

|||||||

|

length |

390 |

420 |

535 |

655 |

||||||||||||||

|

Accuracy * 1 |

Clockwise: ± 2% Counterclockwise: ± 2.5% |

Clockwise: ± 2.5% Counterclockwise: ± 3.5% |

||||||||||||||||

|

Data storage capacity |

100 |

|||||||||||||||||

|

Operating mode |

Peak hold (P) / real-time mode (T) |

|||||||||||||||||

|

unit |

N.m, in.lb, ft.lb, kgf.cm |

|||||||||||||||||

|

Ratchet head form |

Two-way ratchet head |

|||||||||||||||||

|

Ratchet head teeth |

36 |

48 |

||||||||||||||||

|

Number of keys |

5 |

|||||||||||||||||

|

battery |

2 1.5V AAA batteries |

|||||||||||||||||

|

Operating temperature |

-10 ℃ ~ 60 ℃ |

|||||||||||||||||

|

storage temperature |

-20 ℃ ~ 70 ℃ |

|||||||||||||||||

|

humidity |

90% without condensation |

|||||||||||||||||

|

Drop test height |

1 meter |

|||||||||||||||||

|

Vibration test conditions * 2 |

10G |

|||||||||||||||||

|

Life test * 3 |

10000 times |

|||||||||||||||||

*: Please refer to the comments at the back of the table

note:

* 1. The accuracy guarantee range is 20% to 100% of the maximum operating value, and the last digit is ± 1. Torque accuracy is the normal value. The correction accuracy is based on the middle groove of the five grooves on the grip as the correction point. To ensure accuracy, it is recommended to calibrate once a year.

* 2. Life test includes horizontal test and vertical test.

* 3, \"Once \" means to apply the wrench from 0N.m to the maximum operating setting value of the wrench, and then return to 0N.m.

4. Precautions before using the wrench

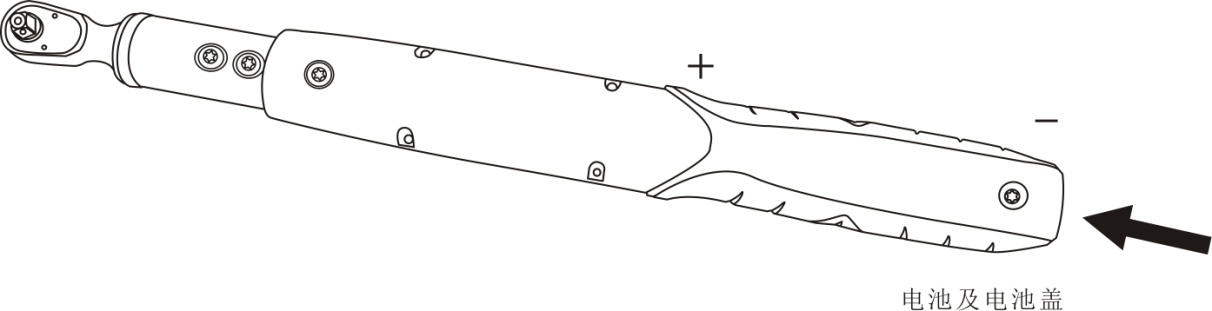

4.1. Insert the battery

4.1.1. Take out the battery cover.

4.1.2. Put two No. 5 batteries into the battery box, please pay attention to the positive and negative directions.

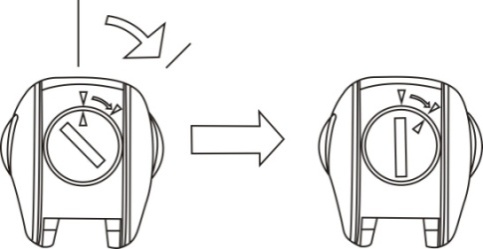

4.1.3. Close the battery cover, and rotate the battery cover to the position shown below and below.

4.2. Power on and reset

4.2.1. Press \"C \" to turn on the wrench

4.2.2. After the power is turned on, before using it, press \"C \" to reset the wrench

note:

1. If the wrench has external force applied to the wrench before turning on the power, an offset value will be displayed on the screen after turning on the power / resetting.

2. \"N.m \" and \"T \" are loaded from EEPROM. Once the user changes the unit or mode, there will always be EEPROM.

4.3 Wake up the wrench during sleep

4.3.1. In order to save power, if there is no operation. It will enter sleep mode after about 5 minutes. Press \"C \" to wake up the wrench

4.4 Low voltage protection

4.4.1. If the system detects that the battery voltage is lower than 2.2V, the wrench will cut off the power; when the wrench voltage is lower than 2.2V, the wrench will automatically shut down.

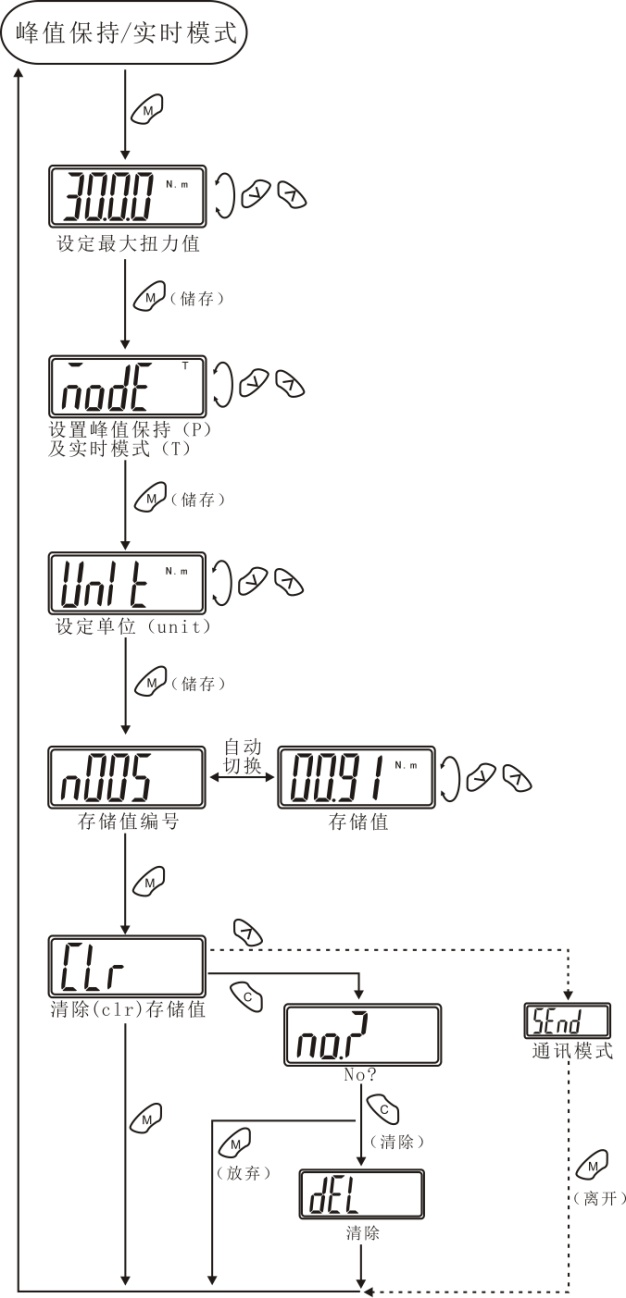

5. Setting

note:

1. If there is no data in the memory, the screen displays \"n000 \", and then automatically switches to the stored value \"0000 \".

2. The communication mode is used to upload records to the computer.

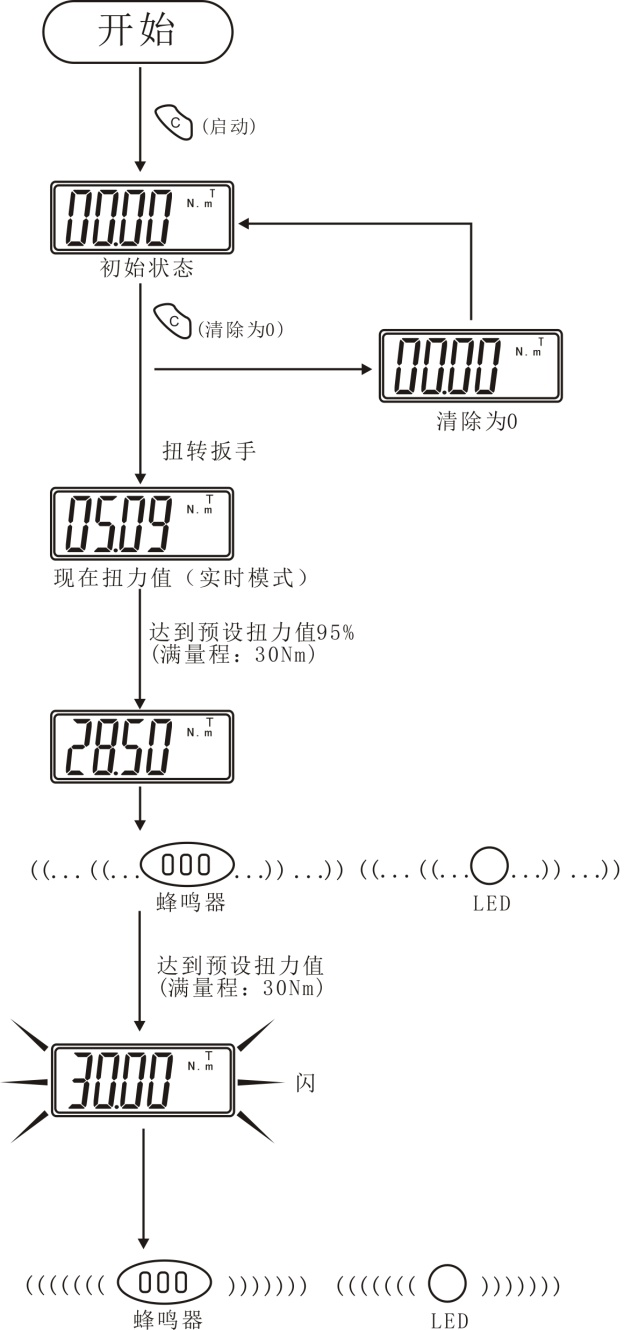

Six, real-time mode

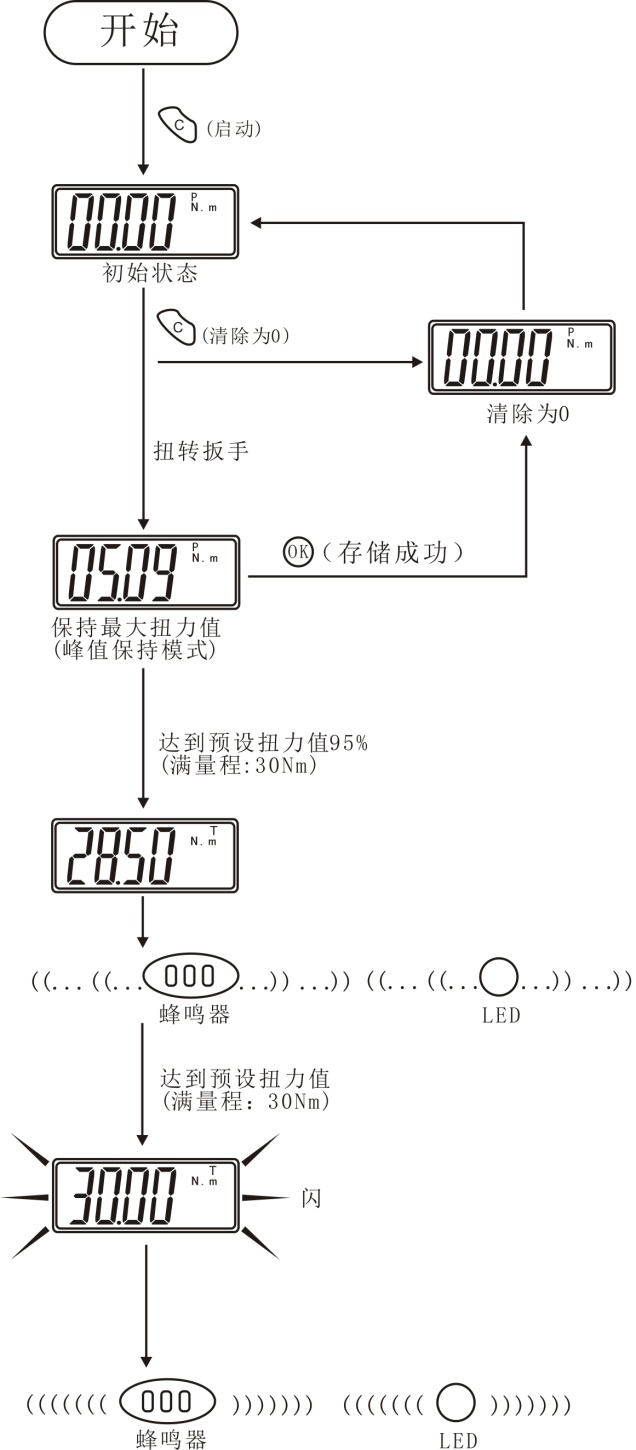

Seven, peak hold mode

8. Communication function

8.1. Connect the communication cable

8.1.1. After turning off the power of the wrench, use the attached communication cable to connect the computer communication hole and the wrench.

8.2. Upload stored value

8.2.1. Make sure that the PC and wrench are properly connected.

8.2.2. Press the wrench operation mode to \" \". (Refer to \" Settings \"chapter)

\". (Refer to \" Settings \"chapter)

8.2.3. Start uploading software on the PC.

8.2.4. When uploading the software, first select the correct Com No and click \"Port Open \" to open the port.

8.2.5. Next, click the upload button to transfer the stored value to the computer.

8.2.6. Finally, click \"Export \", the system will automatically open the uploaded data in Excel format.

8.2.7. Select the appropriate storage path to save the data table you uploaded.

Nine, maintenance and storage

9.1 Note:

In order to maintain good accuracy, it is recommended to recalibrate once every year.

9.2. Excessive torque may cause damage or loss of accuracy (more than 105% of the maximum torque range).

9.3 Do not shake the wrench violently or drop the wrench on the ground.

9.4 Do not use the wrench as a hammer.

9.5. Do not place the wrench in high temperature, high humidity or direct sunlight.

9.6 Do not use wrenches near water.

9.7 If you accidentally get the wrench wet, please wipe it dry with a dry towel immediately. Salt in the sea water may damage the wrench.

9.8 Do not use organic solvents to clean the wrench, such as alcohol or paint thinner.

9.9 Do not put the wrench near magnetic objects.

9.10. Do not place the wrench in a place where there is a lot of dust or sand. This will cause serious damage to the wrench.

9.11. Do not press the LCD screen heavily.

Ten, battery handling

10.1. If the torque wrench is not used for a long time, please remove the battery.

10.2. When you need to travel long distances or in cold areas, please prepare spare batteries.

10.3. Do not mix batteries of different brands, and do not mix new and old batteries.

10.4. Sweat, oil, etc. will hinder the contact of the battery electrodes. Please wipe the battery clean before putting in the torque wrench.

10.5. Please discard the used batteries in the designated recycling place. Do not put the battery into fire.

11. List of random attachments

|

1 |

Digital torque wrench |

1 |

|

2 |

Instructions |

1 serving |

|

3 |

Battery cover key |

1 |

|

4 |

Certificate of conformity |

1 serving |

|

5 |

Warranty Card |

1 serving |

|

6 |

Inspection certificate |

1 serving |

|

7 |

Desiccant |

1 package |

|

8 |

5 # battery |

2 knots |