I. Overview:

AYQ preset torque driver is used for tightening and tightening workpieces with torque requirements. The product operates clockwise and counterclockwise, and the torque value can be preset. If the screwdriver is idling beyond the set value, the thread tightening can be controlled preferentially. It is suitable for the occasions that have high requirements for screw locking and precision of screw locking and circuit board fixing of precision instruments. Widely used in various electrical, light industry, machinery manufacturing, scientific research structure and other industries.

2. Features:

1. The torque value can be preset, and there is an audible alarm prompt. When the tightening torque of the fastener reaches the preset torque value, it will automatically send out a signal \"click\", accompanied by obvious vibration of the hand, which prompts the completion of the work. After the force is released, all related parts are automatically reset.

2. Automatic switching in reverse direction, easy to use in both directions.

3. Adopt the scale ring and scale wheel, the scale line reading is clear and accurate.

4. Forged aluminum alloy material, durable and long life.

5. This torque screwdriver implements the relevant regulations of GB / T 15729——2008.

6. Two Phillips screwdriver heads are included, allowing customers to replace the screwdriver heads according to the items they want to measure.

3. Specifications:

|

model |

AYQ-0.6 |

AYQ-1.2 |

AYQ-3 |

AYQ-6 |

|

|

Range |

0.1 ~ 0.6 (N.m) |

0.2 ~ 1.2 (N.m) |

0.5 ~ 3 (N.m) |

1 ~ 6 (N.m) |

|

|

Index value |

0.01N.m |

0.02N.m |

0.05N.m |

0.1N.m |

|

|

Accuracy |

± 4% |

||||

|

Dimensions |

161mm |

186mm |

|||

|

Handle diameter |

Φ26mm |

φ31mm |

|||

|

Connector size |

6.35 hexagon |

||||

|

net weight |

About 0.3Kg |

About 0.4Kg |

|||

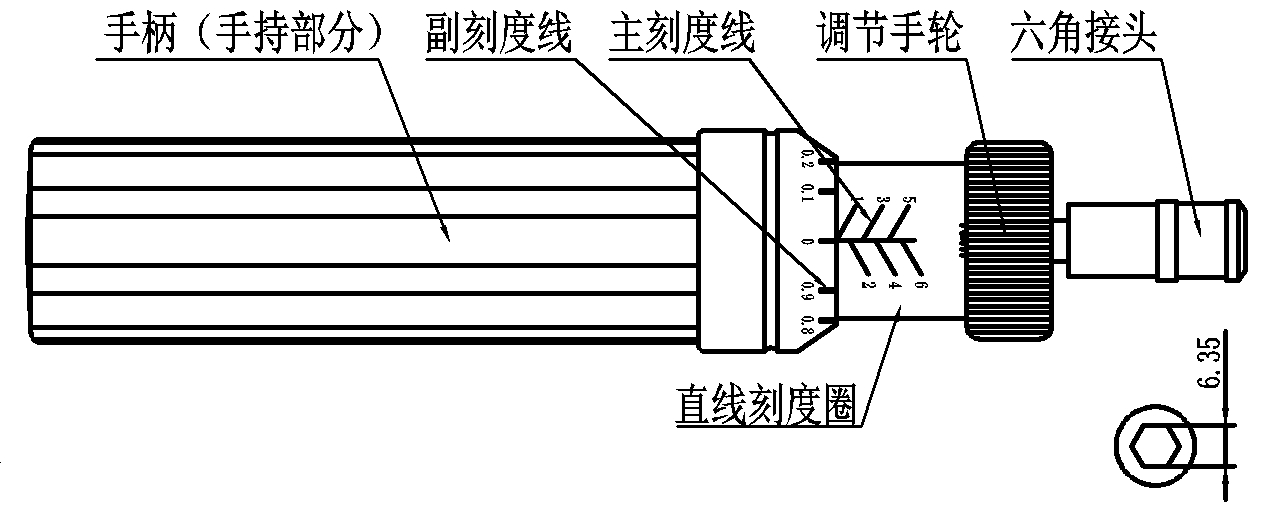

4. Product structure:

5. How to use:

1. Set the torque value of this screwdriver according to the torque required for tightening the fastener; when presetting the torque value, first hold the hand-held part with the other hand, hold the adjustment handwheel with the other hand, and turn it toward the linear scale ring Press in the direction, and then rotate the adjustment handwheel clockwise to drive the linear scale ring, so that the values of the main scale line and the auxiliary scale line reach the required torque value, and then release the adjustment handwheel to complete the preset torque value.

2. According to the form of the head of the fastener, select the bit from the accessory and insert it into the hexagonal joint of this screwdriver (if there is no suitable bit in the accessory, you can process the bit for connection by yourself. The size of the hexagonal joint is as shown in the above figure. Show).

3. Install a screwdriver of the corresponding specification on the screwdriver, hold the handle to align the screwdriver with the fastener, and turn the screwdriver until the tightening torque of the fastener reaches the set value, the screwdriver idling occurs. An audible signal, accompanied by obvious hand vibration, prompts the completion of the operation.

4. If it will not be used for a long time, adjust the scale to the minimum torque value and place it.

Six, matters needing attention:

1. This product is only suitable for tightening and testing within the calibration range.

2. Do not strongly impact during use.

3. It is absolutely not allowed to be used as another tool.

4. Please don't continue to apply force after the driver's\"click\" alarm.

5. The measured value of this product has been corrected, and it is not allowed to disassemble it privately, so as not to cause errors in the measurement accuracy.

6. After use, the torque value should be adjusted to zero position to maintain the accuracy of the screwdriver and extend the service life.

7. Do not contact this product with acids, alkalis, and corrosive gases.

Seven, maintenance instructions:

1. Please contact the original place of purchase or our company if a fault occurs.

2. This product has quality problems within one month from the date of sale, under normal use and without damage to the appearance. The original customer invoice, valid warranty card and complete packaging are sent to the original place of purchase or the company replaces the product of the same specification and model. The replaced product will continue the warranty period and terms of the original product.

3. This product is within one year from the date of sale. Under normal use, non-human faults are covered by the warranty (users disassemble the machine or repair it at other maintenance points. The company does not guarantee the warranty). The warranty card can be contacted to the original place of purchase for a free one-year warranty.

4. The warranty clause of this product is only applicable to this series of products sold in the Chinese market. For products that exceed the replacement period and warranty period, customers can consult the original purchase place for repairs or contact the company, which will provide paid repair .

Eight, packing list:

|

Numbering |

name |

Quantity |

|

1 |

Packing box |

1 |

|

2 |

body |

1 |

|

3 |

First batch |

2 |

|

4 |

Product Manual |

1 |

|

5 |

Product certificate and warranty card |

1 |

|

6 |

Desiccant |

1 |