AEL single column vertical machine instruction manual

1. Function:

AEL single-column vertical machine is a push-pull load test stand specially used for HF series and NK series push-pull force gauges. This product adopts double pole structure, which has the advantages of good stability, wide application range, convenient use, etc., and has stepless speed regulation, manual (jog), automatic control switching functions. It is suitable for the testing of push-pull load, insertion force, destruction test of rubber and plastic, light industrial textile, building doors and windows, composite materials, wire and cable, auto parts, power machinery, scientific research institutions and other industries.

2. Features:

1. Electric loading, stepless speed regulation, gear transmission

2. Compact structure and stable transmission

3. The operation is simple and can be used in combination with various fixtures

3. Specifications:

· Maximum load: 500N

· Effective stroke: 200mm 400mm 700mm optional

· Test speed: 0-280 mm / min

· Working voltage: 220V

· Dimension (mm): 280 * 340 * 780 (200mm) 280 * 340 * 980 (400mm) 280 * 340 * 1270 (700mm)

· Net weight: 30kg

Four, dynamometer installation method:

Built-in sensor: put 4-M6 screw into the 4-φ6.2 hole of the fixing block, insert a washer in the thread direction, and tighten it with the 4-M6 thread on the dynamometer mounting plate to install the dynamometer On the board, the dynamometer mounting holes are divided into two groups, 30x145 and 40x90, respectively. Users can determine according to their needs.

5. How to use the control panel:

1. Power switch: When the button is pressed, the power is turned on, and when pressed again, the power is turned off.

2. Speed control: Due to the different measured objects and user requirements, when adjusting the knob of the governor, the movement speed of the carrier is 20 ~ 200mm / min.

6. Function control:

Manual / Automatic, when the knob is turned to manual, if you move the carrier, you need to press the up or down key, and the movement will stop when disconnected. When the knob is turned to automatic, if the carrier moves, press the up or down key directly.

Seven, itinerary adjustment:

There are two screws on the rear side of the column, which are loosened with the standard hexagon wrench, adjusted to the appropriate position, and the sliding block is controlled to meet the requirements.

8. How to use the counter:

The upper part of the counter is a digital display screen to record the number of tests, and the lower part is a total of four preset buttons, from left to right are one, ten, one hundred, one thousand, indicating that the preset can be set in the range of 0 ~ 9999. For example: the user performs continuous testing on a certain product, the number of tests is 9999, need to be adjusted on 4 buttons, adjust to display as 9999, and then press the manual / automatic button, you can test 9999 times, after running 9999 times automatically Stop, if you need to test again, just press the stop button.

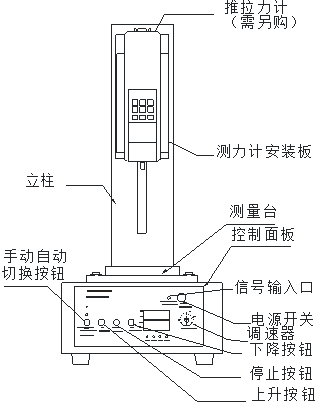

Nine, structural diagram: