Electric vertical double column machine

1. Function:

The electric vertical double-column testing machine is a push-pull load test stand specially used for digital display and pointer push-pull force gauge series. This product adopts double pole structure, which has the advantages of good stability, wide application range, convenient use, etc., and has stepless speed regulation, manual (jog), automatic control switching functions. Suitable for rubber and plastic, light industrial textiles, building doors and windows, composite materials, wires and cables, auto parts, power machinery, scientific research institutions, etc.

The industry's push-pull load, insertion force, destruction test and other tests.

2. Features:

■ Electric loading, stepless speed regulation, gear transmission;

■ Compact structure and stable transmission;

■ Simple operation and can be used in combination with various fixtures.

3. Specifications:

· Maximum load: 5000N;

· Effective stroke: 220 / 450mm;

· Test speed: 60 ~ 240 mm / min;

· Working voltage: 220V;

· Dimensions: (mm): 640x400x2400;

· Net weight: 56 (58 for heightened type) kg.

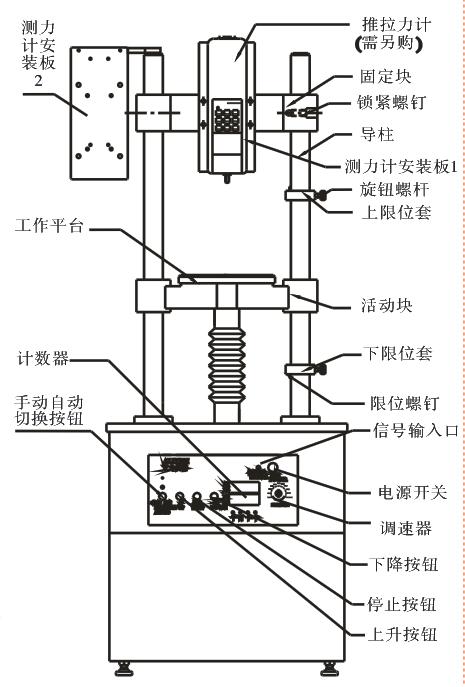

Fourth, the structure diagram (as shown on the right):

Five, dynamometer installation method:

1. Built-in sensor: thread the 4-M6 screw into the 4-φ6.2 hole of the fixing block, insert a washer in the thread direction, and tighten the 4-M6 thread on the dynamometer mounting plate 1 to measure On the force gauge mounting plate 1, the force gauge mounting holes are divided into two groups, 30x145 and 40x90, respectively. Users can determine according to their needs;

2. External sensor type: first remove the meter mounting plate 1, and then insert the 2-M8 screw into the 2-φ8.5 hole of the fixing block, so that the external sensor connection block and the fixing block are firmly connected, and the M12 nut is inserted The through hole of the connecting rod should be connected firmly with the sensor, and the control system can be installed on the dynamometer mounting plate 2.

6. Height adjustment of dynamometer:

There is a locking screw on both sides of the fixed block of the electric vertical double-column test machine. First, loosen the locking screw, and then move the fixed block up or down to the required height, and then tighten the locking screw Just lock it.

Seven, itinerary adjustment:

There are two stroke limit screws on the guide post (Note: The limit screws are prohibited to be disassembled). The limit sleeve is only allowed to move within the stroke range. Adjust the position of the limit sleeve according to the user's measurement to achieve the purpose of use.

8. How to use the control panel:

1. Power switch: when the button is pressed, turn on the power, press it again, the power is off;

2. Governor: control the moving speed of the active block within the adjustment range of 0 ~ 240mm / min, the user can choose the appropriate moving speed according to their requirements;

3. UP button: move the working platform upward;

4. STOP button: stop the working platform from moving;

5. DOWN button: make the working platform move downward;

6. Manual / automatic switch button: A. When the button is switched to manual, if you want to make the working platform move, you need to press and hold the UP button or press and hold the DOWN button, when you release the UP ) Or DOWN button to stop the movement; B. When the button is switched to automatic, if you want to move the working platform, you can directly press the UP or DOWN button to continue the round-trip movement, press Stop (STOP) button is dynamic stop;

7. How to use the counter: There are two lines of digital display on the counter, the upper is the recording test times (that is, the real-time measurement times), and the lower is the preset buttons, a total of 4, from left to right are respectively, ten, hundred, Thousands, indicating that the preset can be set in the range of 0 to 9999 (the preset is an arbitrary setting). For example: the user performs continuous testing on a certain product, the number of tests is 9999, need to be adjusted on 4 buttons, adjust to display as 9999, and then press the manual / automatic button, you can test 9999 times, after running 9999 times automatically Stop, if you need to test again, just press the stop button.

Nine, matters needing attention:

The power supply of the equipment must have a ground wire (ground resistance must be ≤ 4 ohms).

Ten, warranty:

During testing, the micro switch is guaranteed within 100,000 times, exceeding the number of uses, the above accessories

Charge for costs.